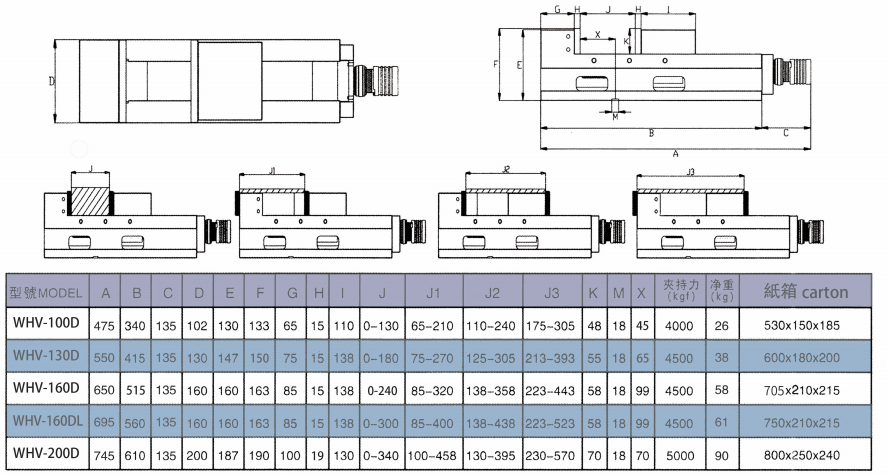

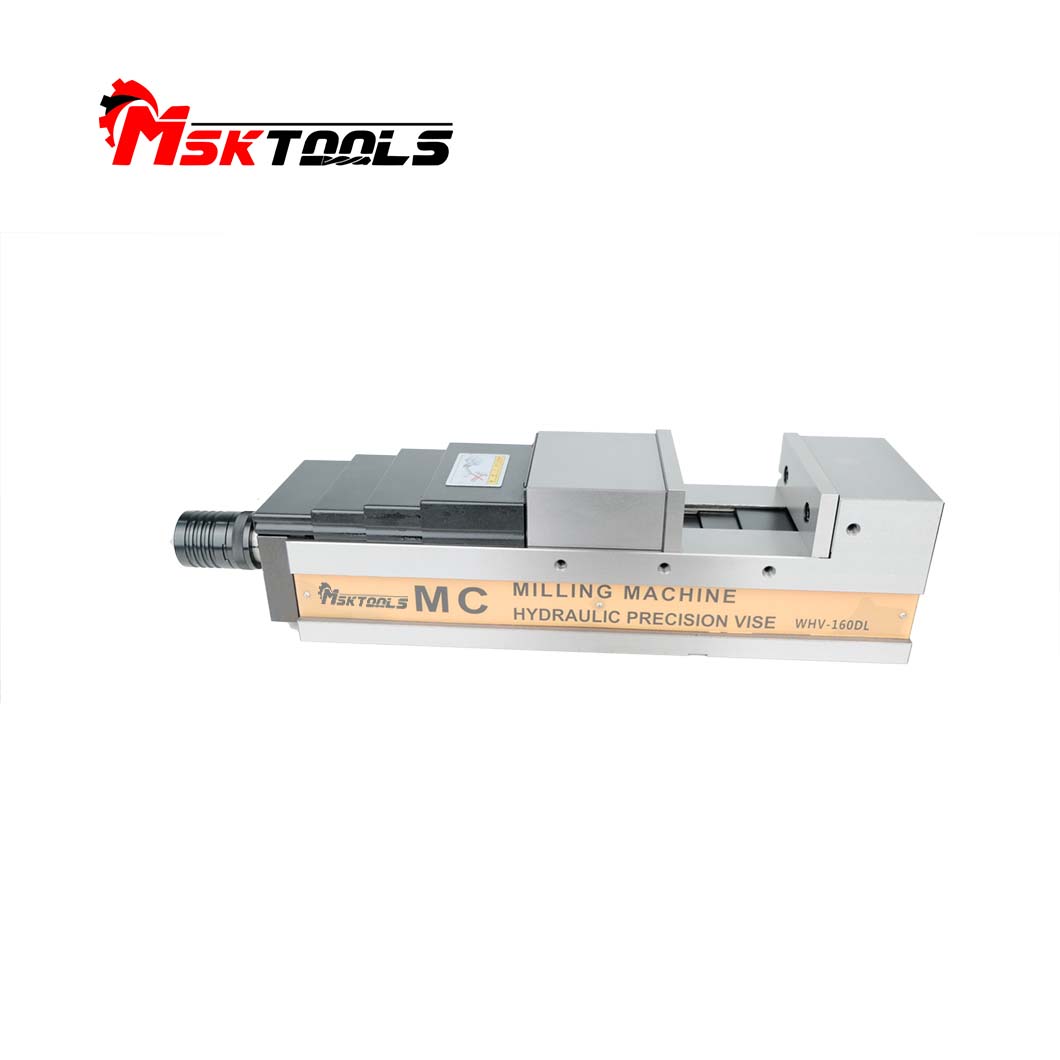

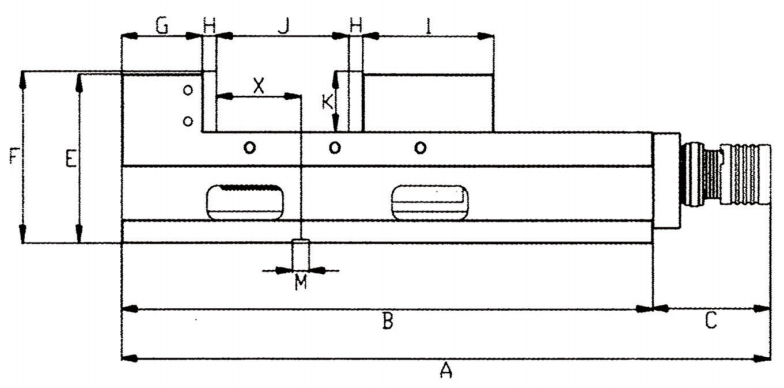

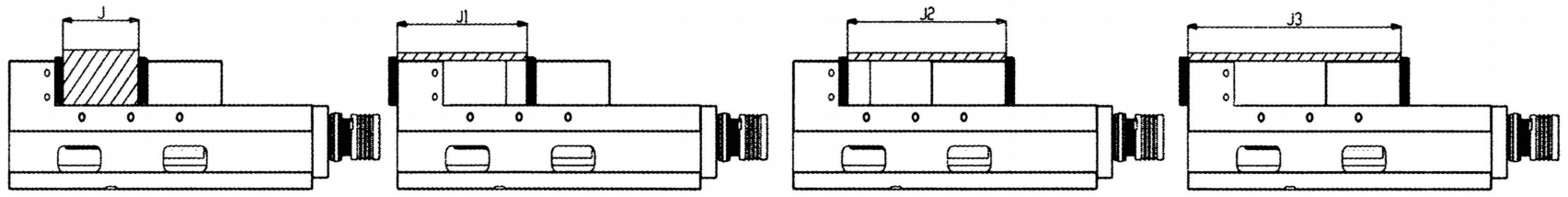

MC Power Machine Vise-Hydraulic Type

The MC Power Machine Vise-Hydraulic Type flat-jaw vise is manufactured using precision machining and grinding processes, making it suitable for precision machining on vertical/horizontal machining centers. Its body is integrally cast from high-ductility ductile iron, and the slide rails and jaws are heat-treated and hardened, combining high precision, high wear resistance, and superior clamping force. A patented design enables rapid pressure induction, and it is equipped with a chip-resistant structure to effectively extend its service life.

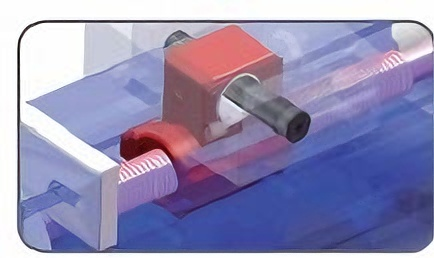

Built-in anti-floating transmission mechanism

The downward force also acts during clamping, so the amount of floating of the workpiece and the movable body is minimal. The main body and the fixed jaws are an integrated structure, which can effectively prevent the clamp body from tipping over.

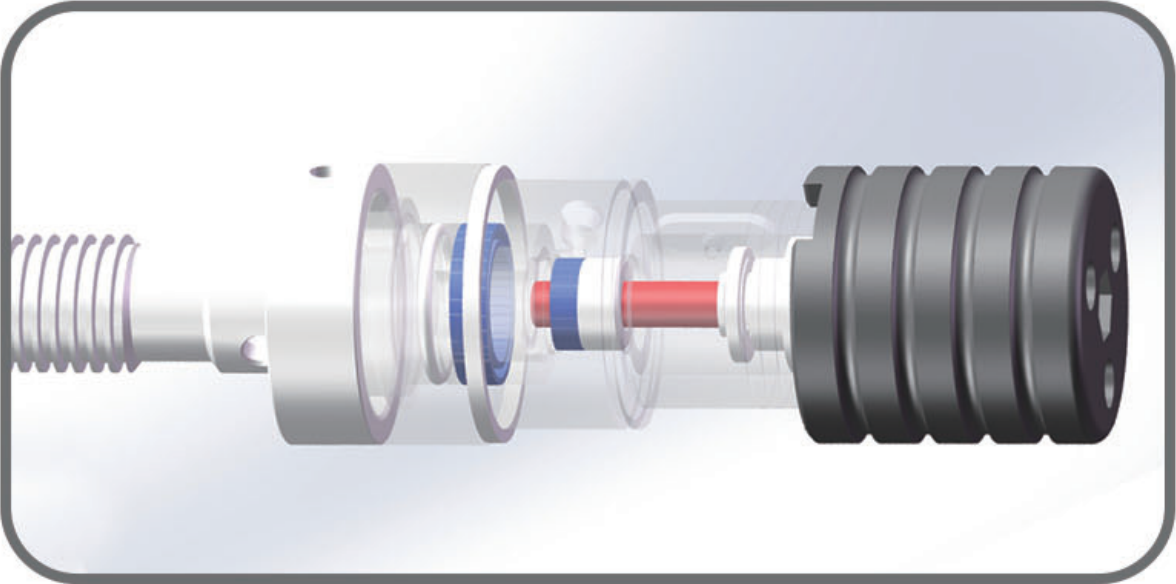

The unique hydraulic sealing structure helps you achieve safe and pressure-free operation.

The MC precision hydraulic vise is designed for heavy-duty machining and is suitable for vertical and horizontal machining centers and FMS systems.

Manufactured from a single piece of high-tensile ductile iron, its robust structure is resistant to deformation. Combined with a hardened sliding surface with a hardness of HRC42 or higher, it ensures long-term wear resistance and machining stability. The precision hydraulic force-multiplying mechanism provides powerful and convenient clamping force, while its unique one-piece vise design effectively reduces backslip during clamping, ensuring machining accuracy and operational safety.

What customers say about us

FAQ

1. What machining scenarios is this vise suitable for?

It is specifically designed for precision heavy-duty cutting, suitable for vertical or horizontal machining centers, and compatible with FMS (Flexible Manufacturing System), capable of stably performing various cutting operations from light to heavy-duty.

2. How does the product's structure ensure high precision and high rigidity?

The vise employs three core design features:

One-piece molding: The body and fixed jaws are a single unit, significantly reducing jaw tilting and body leaning during clamping, ensuring rigidity.

Anti-lift mechanism: A downward force is generated during clamping, effectively suppressing the workpiece and movable jaws from lifting, improving positioning accuracy.

Wear-resistant treatment: The sliding surfaces of the body and jaws are hardened to a hardness of HRC42 or higher, ensuring long-term precision and wear resistance.

3. What are the unique advantages of its hydraulic system?

The hydraulic system boasts two highlights:

Precision force-boosting design: Provides a powerful clamping force of up to 5000 kg, with convenient operation and rapid pressurization.

Unique Sealing Structure: The optimized sealing device achieves safe, reliable, and "zero-pressure relief" functionality, ensuring stable and undiminished clamping force during machining.

4. What are the material characteristics?

The vise body is made of high-tensile-strength ductile iron (FCD600), with a tensile strength of 60 kgf/mm² (approximately 80,000 psi). This material possesses excellent strength and toughness, allowing the vise to remain stable and resistant to deformation under heavy cutting.

5. Are there any special designs for machining environments?

Yes. The product is designed with an anti-chip structure that effectively prevents chips from falling into the vise, and the internal structure facilitates the removal of any chips that have already entered. This design reduces maintenance needs and significantly extends the equipment's service life.

The MC series precision hydraulic vise is an industrial-grade clamping tool designed for modern, demanding machining environments. It integrates a high-rigidity structure, precision hydraulic force amplification, and an innovative anti-floating design, aiming to provide a powerful, precise, and reliable workpiece clamping solution for vertical and horizontal machining centers and flexible manufacturing systems. It is particularly suitable for a wide range of demanding machining tasks, from light to heavy cutting.

Core Design and Components

One-piece high-strength body: The vise body is cast from a single piece of high-tensile-strength ductile iron. The integrated design of the body and the fixed jaws creates an extremely stable and rigid foundation, fundamentally eliminating the tipping and backward tilting problems caused by the structural separation of traditional vises.

Precision hardening treatment: All key sliding surfaces and jaws are hardened to a hardness of HRC42 or higher, ensuring long-term dimensional stability and excellent wear resistance.

Patented Hydraulic Force-Boosting Mechanism: Built-in unique hydraulic seals and force-multiplying structure enable rapid generation of a powerful clamping force of up to 5000 kg, while ensuring easy operation and stable pressure without loss.

Concealed Anti-Floating Transmission Mechanism: An innovative mechanical design generates a downward force simultaneously during clamping, effectively preventing the workpiece from floating upwards from the movable jaws.

Anti-Chip Design: A specially designed structure prevents metal chips from entering the vise, and the internal chip removal is easy, extending service life and reducing maintenance requirements.

Core Functions and Advantages

Superior Rigidity, Rock-Solid Stability: The integrated high-rigidity structure ensures that the vise body remains undeformed and tilt-free during heavy cutting, guaranteeing machining accuracy.

Powerful Clamping, High Efficiency and Labor Saving: The patented hydraulic mechanism achieves rapid pressure boosting and superior clamping force, balancing efficiency and safety.

Precision Anti-Float, Enhanced Accuracy: The active anti-float design minimizes workpiece float, making it ideal for machining applications requiring high perpendicularity and repeatability.

Durable Wear Resistance, Easy Maintenance: Hardened key components and chip-resistant design ensure the vise maintains long-term accuracy and reliability even in harsh machining environments.

Typical Applications:

Precision Machining: Suitable for machining molds, aerospace components, automotive precision parts, and other applications requiring extremely high clamping rigidity and precision.

Automated Production Lines: Ideal for integration into flexible manufacturing systems, machining center clusters, and automated production lines for efficient and stable batch production.

Heavy-Duty Cutting Tasks: Performs exceptionally well in large-mass milling and drilling operations on difficult-to-machine materials such as steel and cast iron.

Multi-Face Machining: Its high rigidity and anti-float characteristics make it ideal for multi-face machining operations requiring workpiece rotation. Challenges and Design Considerations

In modern high-speed, heavy-duty machining, traditional mechanical vises often face challenges such as insufficient clamping force, workpiece float, insufficient rigidity leading to vibration, and metal shavings intrusion affecting lifespan. The MC Precision Hydraulic Vise is designed to address these pain points:

Overcomes insufficient clamping force with hydraulic amplification.

Solve workpiece floatation with an anti-floating mechanism.

Resist cutting vibration and deformation with a one-piece high-rigidity cast iron body.

Protects against environmental wear with chip-resistant and hardened designs.

The MC Precision Hydraulic Vise is more than just a clamping tool; it's a systems engineering solution integrating materials science, precision mechanics, and hydraulic technology. Through its one-piece high-rigidity structure, patented hydraulic amplification and anti-floating mechanism, and comprehensive wear-resistant and chip-resistant design, it provides high-end manufacturing with the ultimate clamping solution to ensure machining accuracy, improve production efficiency, and reduce overall operating costs. Whether facing precision light cutting or challenging heavy-duty machining, it is a reliable and robust foundation.