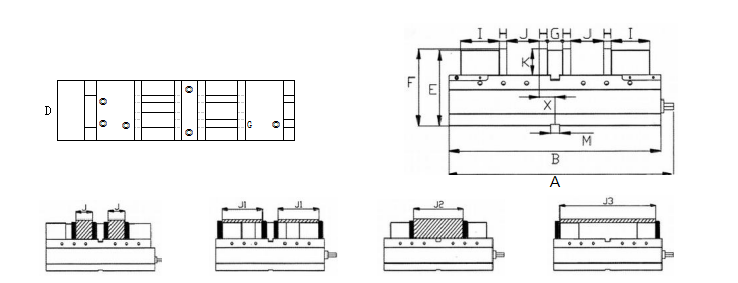

MC Double Lock &Anglock Machine Vise

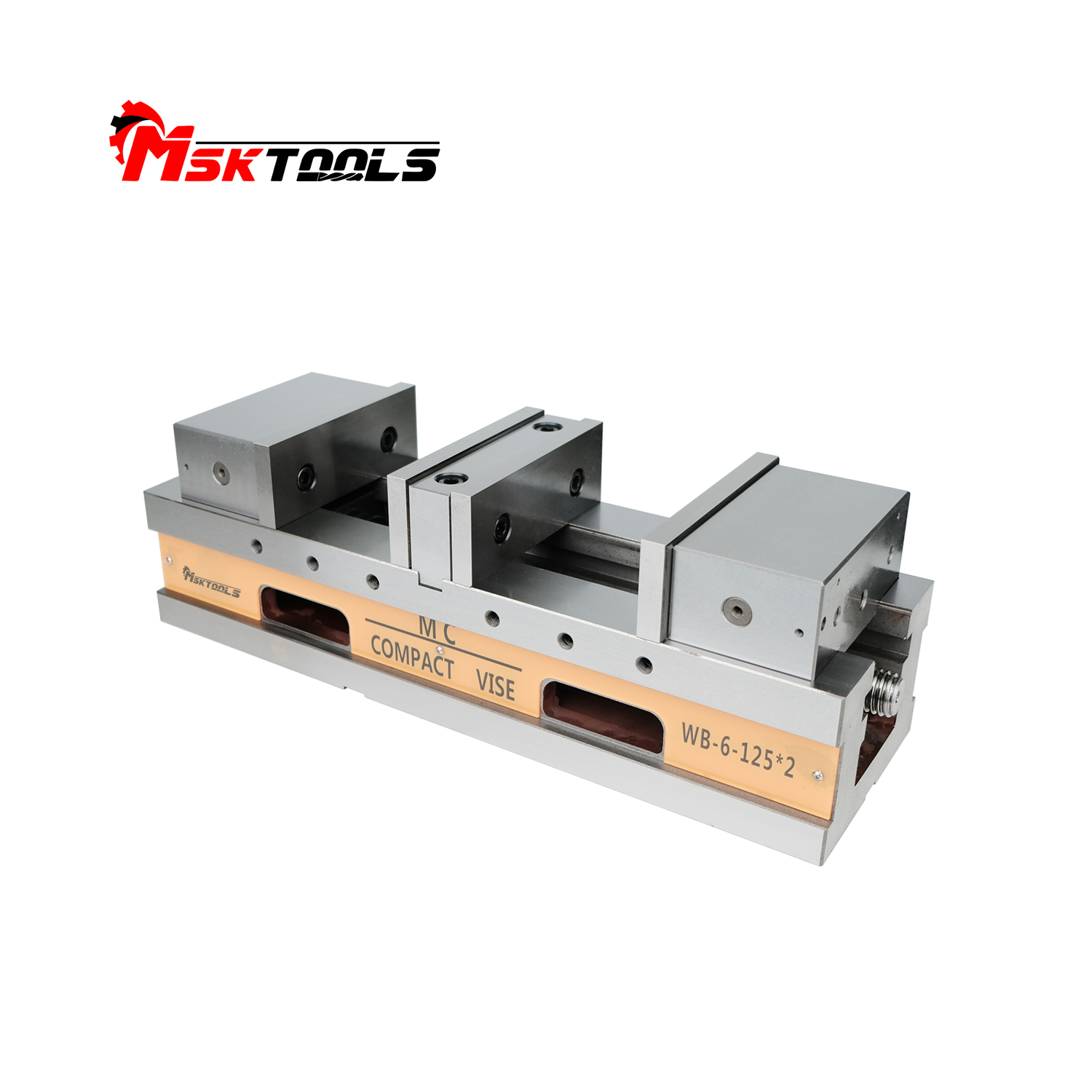

The MC Double Lock & Anglock Machine Vise is made of high-strength ductile iron (FCD600) and features independently adjustable jaws on both sides and a modular design, allowing for flexible expansion of the clamping range and simultaneous machining of two workpieces of different sizes. Its high-rigidity structure, combined with heat-treated guideways (HRC42°), ensures automatic clamping and high-precision positioning on CNC vertical machining centers. Multiple units can be used in combination, significantly improving batch processing efficiency.

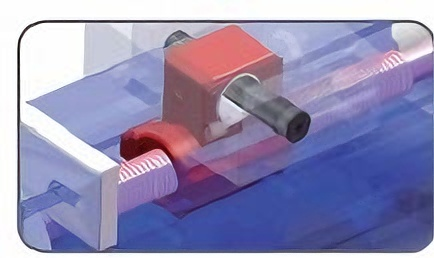

The built-in floating downward transmission can generate a locking force, which can eliminate the upward floating of the gripper plate and the tilting of the working surface.

The MC Double Lock & Anglock Machine Vise is a single-piece cast vise made of high-tensile-strength ductile iron (FCD600), ensuring a robust and deformation-resistant body. The side guides are heat-treated to HRC42°, guaranteeing excellent wear resistance and high precision for long-term use.

Its core dual-jaw mechanism allows for independent adjustment of the opening, supporting the simultaneous clamping of two workpieces of different sizes. The clamping range can be expanded by disassembling the intermediate module. Combined with an automatic workpiece pressing design, it performs stably and efficiently on CNC vertical machining centers. Multiple units can be combined for multi-unit operation, significantly improving batch processing efficiency.

What customers say about us

FAQ

1. What are the core advantages of this vise?

The core advantage of this product lies in its "dual-station, high efficiency." It allows you to process two workpieces of different sizes simultaneously in a single clamping operation and can be used in combination with multiple machines, greatly improving the utilization rate of CNC machine tools and batch processing efficiency.

2. What size workpiece can it clamp? Is the clamping range fixed?

The clamping range can be flexibly expanded. The standard configuration is suitable for workpieces of common sizes. When larger workpieces need to be clamped, simply remove the middle jaw module to extend the clamping distance, overcoming the limitation of insufficient opening in traditional vises.

3. How is machining accuracy and stability guaranteed?

We ensure high accuracy and stability through a triple design:

High-strength material: The vise body is made of FCD600 ductile iron, which has strong resistance to deformation.

Key component hardening: The sliding guide rails on both sides are heat-treated to HRC42°, with high wear resistance, ensuring a long-term precision lifespan.

Automatic Downward Pressure and Anti-Floating: The built-in floating downward pressure transmission mechanism generates downward pressure during locking, effectively preventing the workpiece from floating or tilting during machining.

4. What do "fixed height" and "multiple units can be used together" mean in the product information?

"Fixed height" refers to the consistent height of the critical installation and positioning dimensions of all vises. This allows multiple vises to be easily and seamlessly installed side-by-side and precisely aligned on the machine tool table, facilitating the rapid construction of large-scale workpiece clamping matrices, ideal for high-volume order production.

5. What types of machine tools is it primarily suitable for?

This product is specifically optimized for CNC vertical machining centers. Its structural rigidity, automatic downward pressure function, and precision characteristics perfectly match the high-efficiency, high-precision machining requirements of these machine tools, making it an ideal fixture for enhancing the productivity of modern CNC workshops.

Product Introduction

This product is a high-efficiency, high-precision modular double-station vise designed specifically for modern CNC machining centers. Its core advantage lies in its ability to simultaneously clamp and process two workpieces of different sizes, and it supports multi-unit combination expansion, making it an ideal fixture solution for mass production and improved production efficiency.

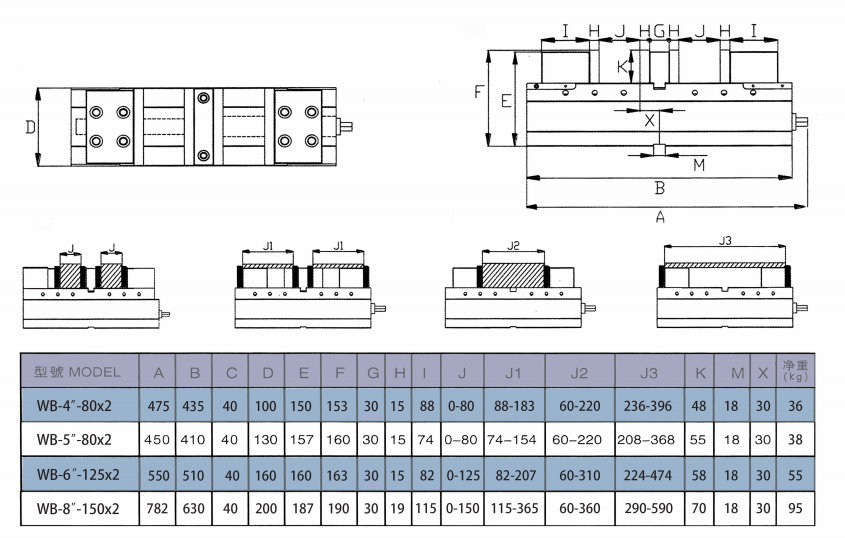

Design and Composition

Main Body Material: The vise body is made of high-tensile-strength, high-ductility ductile iron (FCD600, tensile strength ≥60 kgf/mm²), ensuring overall rigidity and resistance to deformation.

Key Components:

Dual Independent Jaw Mechanism: The opening range of the two jaws can be adjusted independently.

Modular Jaw Design: The middle jaw block is detachable for flexible changes in clamping range.

Hardened Guide Rails: The sliding surfaces on both sides are heat-treated to HRC42°, providing extremely high wear resistance.

Built-in Floating Downward Pressure Transmission Mechanism: Integrated inside the vise body, it automatically generates downward pressure during locking.

Core Functions

Simultaneous Dual Workpiece Machining: Two workpieces can be machined in a single clamping operation, doubling efficiency.

Adaptive Clamping Range:** Clamping capacity can be easily expanded by removing the intermediate module to handle larger workpieces.

Automatic Downward Pressure and Anti-Floating:** The built-in mechanism generates a downward locking force during locking, effectively eliminating workpiece float and vise tilting, ensuring stable clamping.

High-Precision Positioning:** The robust cast body combined with hardened guideways provides repeatability and long-term dimensional stability.

High Standardization:** The "height-fixed" design facilitates seamless side-by-side combination of multiple vises on the machine tool table, creating large-scale workpiece matrices.

Application Scenarios:** Suitable for various CNC vertical machining centers.

Metalworking scenarios requiring small-batch, multi-variety, or medium-batch production.**

Precision parts manufacturing with high requirements for machining accuracy and clamping efficiency.**

Value in Precision Machining:** This product, through its high-rigidity material, anti-floating design, and hardened guideways, directly ensures the stability and dimensional accuracy of the machining process. Its "two-piece-per-time" machining mode minimizes machine tool downtime, translating the high-speed cutting capabilities of CNC equipment into tangible productivity.

Challenges and Considerations

Initial Investment: Compared to traditional single-station vises, this product has a more complex structure and higher initial cost.

Process Planning: More meticulous machining sequence arrangement and programming are required to fully leverage the advantages of dual-station machining.

Applicability: Its advantages may not be fully realized for ultra-large or highly irregularly shaped single workpieces.

In summary, this modular dual-station precision vise is an advanced clamping tool designed to improve efficiency and ensure accuracy. It cleverly integrates a robust FCD600 cast iron base, expandable jaw design, and an innovative built-in pressing mechanism, providing powerful process equipment support for manufacturing enterprises pursuing efficient and precise production.