Manufacturer of End Milling Machine Aluminium - Tungsten Carbide Rotary Burrs Burr Bits For Metal – MSK

Manufacturer of End Milling Machine Aluminium - Tungsten Carbide Rotary Burrs Burr Bits For Metal – MSK Detail:

PRODUCT DESCRIPTION

Carbide rotary files are mainly used for power tools or pneumatic tools, and can also be installed on machine tools.

FEATURE

Carbide rotary file is an indispensable advanced tool for fitters and grinding tools. It is characterized by replacing the small grinding wheel with a handle without dust pollution, the service life is equivalent to hundreds of small grinding wheels with a handle, and the processing efficiency is increased by more than 5 times. It is easy to control, simple to use, safe and reliable, greatly reducing heavy manual labor and production costs.

Uses: Carbide rotary files are widely used, and are used in the processing and manufacturing of abrasive tools. Machining of chamfering, rounding and grooves for mechanical odd jobs, cleaning of flash edges of castings, forgings, and welding parts; finishing of pipes, impeller runners, and arts and crafts carving of metal and non-metallic materials (bone, jade, stone) .

NOTICE

1. Before operation, please read the operating speed to select the appropriate speed range (please refer to the recommended starting speed conditions). Low speed will affect product life and surface finish, while low speed will affect product chip evacuation, mechanical chatter and premature product wear.

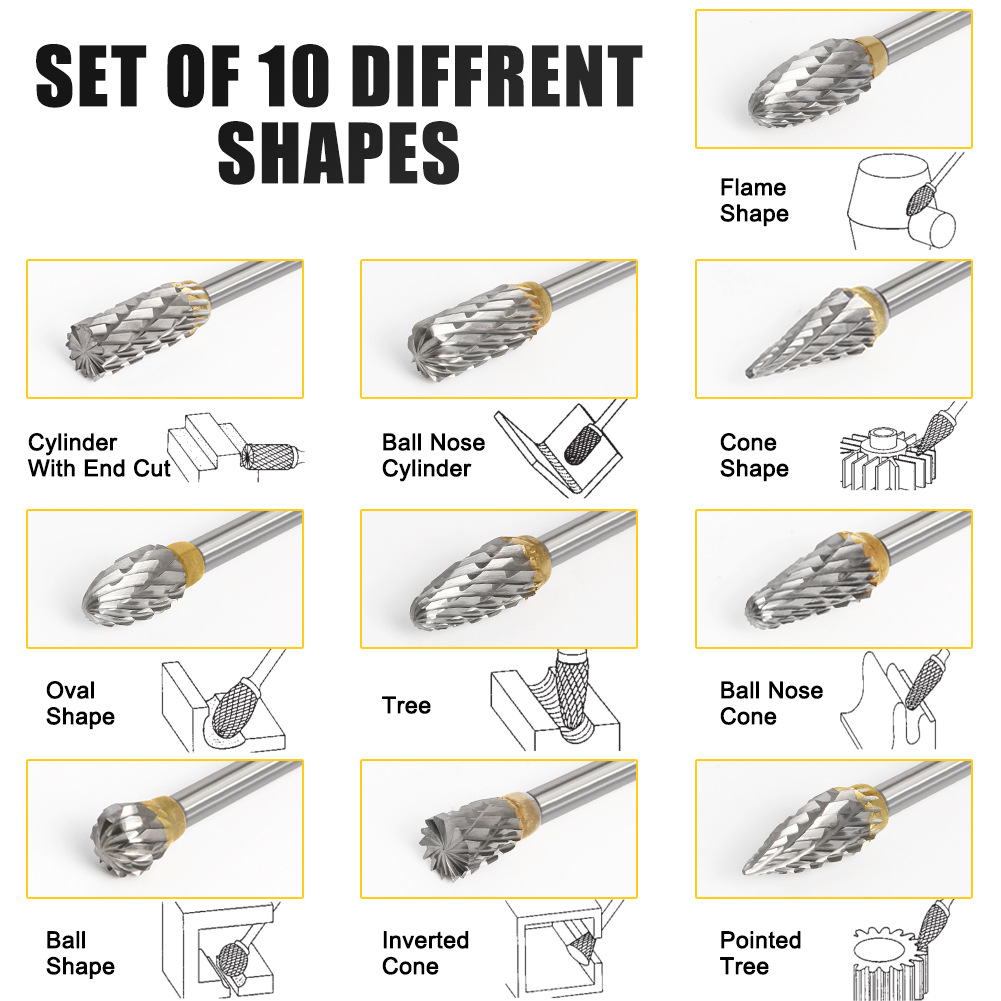

2. Select the appropriate shape, diameter and tooth profile for different processing.

3. Choose a suitable electric grinder with stable performance.

4. The length of the exposed part of the handle clamped in the chuck is at most 10mm. (Except the extension handle, the speed is different)

5. Idling before use to ensure good concentricity of the rotary file, eccentricity and vibration will cause premature wear and workpiece damage.

6. It is not advisable to use too much pressure during use. Too much pressure will reduce the life and efficiency of the tool.

7. Check that the workpiece and the electric grinder are clamped correctly and tightly before use.

8. Wear suitable protective glasses when using.

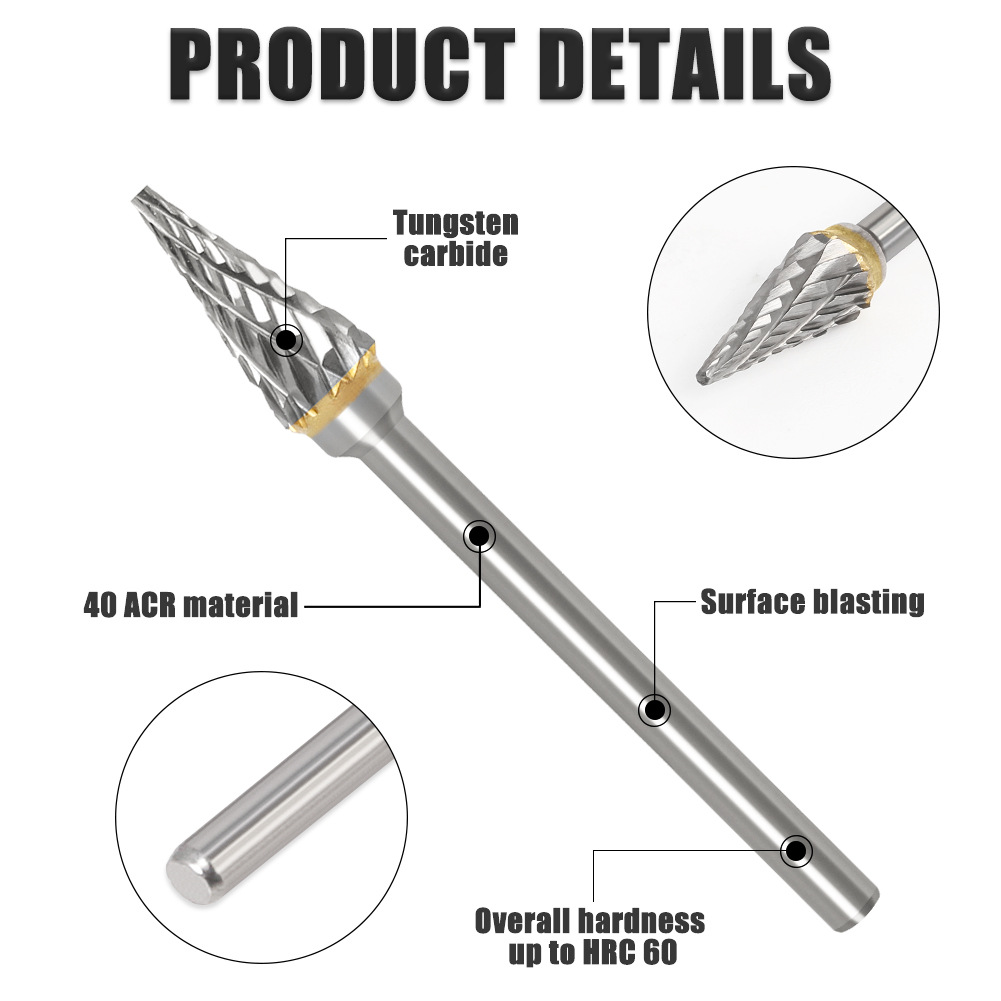

Product detail pictures:

Related Product Guide:

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for Manufacturer of End Milling Machine Aluminium - Tungsten Carbide Rotary Burrs Burr Bits For Metal – MSK , The product will supply to all over the world, such as: Argentina, Cannes, Russia, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.