Low MOQ for Tapered End Mills - HRC70 carbide tungsten ball milling cutter – MSK

Low MOQ for Tapered End Mills - HRC70 carbide tungsten ball milling cutter – MSK Detail:

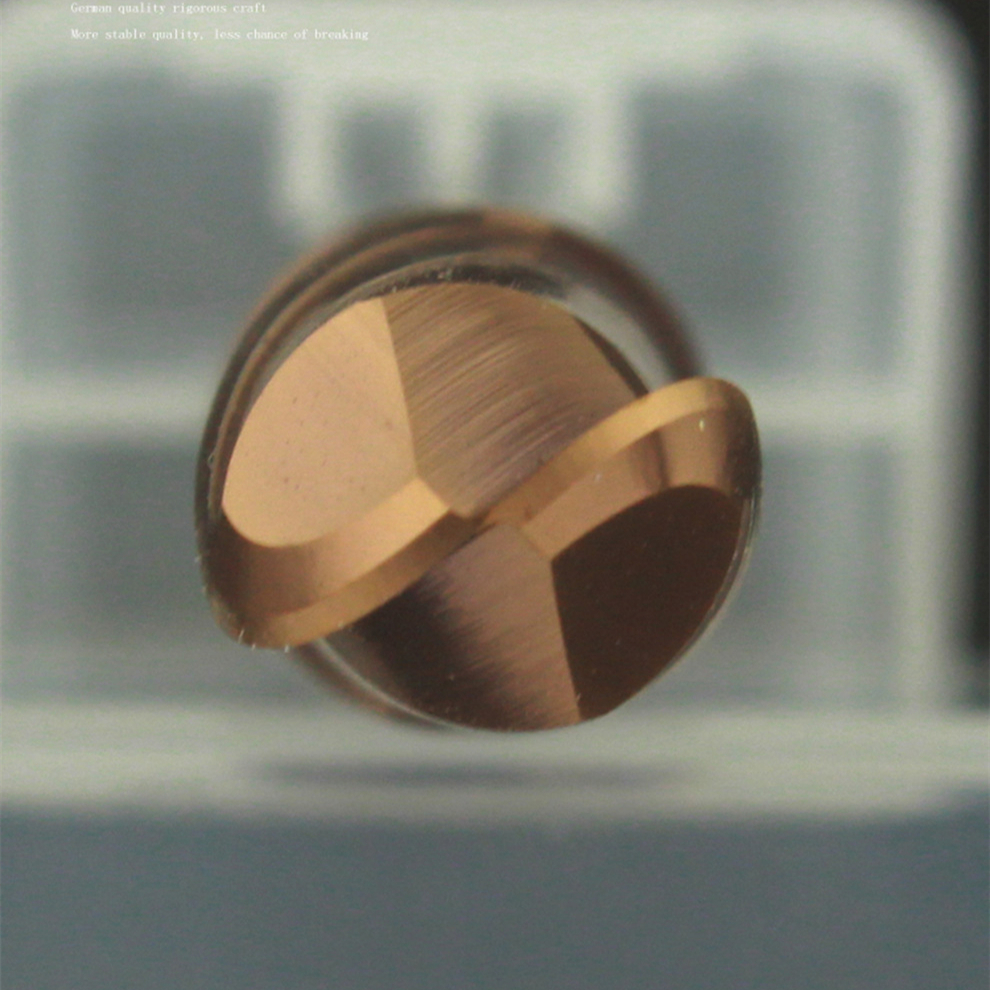

| Product Name | HRC70 carbide tungsten ball milling cutter | Material | Tungsten Steel |

| Workpiece Material | High manganese steel, hardened steel, cast iron, stainless steel, 45# steel, quenched and tempered steel and other difficult-to-process materials | Numerical Control | CNC machining centers, engraving machines, engraving machines and other high-speed machines. |

| Transport Package | Box | Flute | 2 |

| Coating | Yes for steel, no for aluminium | Hardness | HRC55 |

This milling cutter adopts high-hardness bronze nano-coating, specially processing HRC70 hardness workpiece material, so it is called super-hard tungsten steel ball-end milling cutter. Non-standard products, need to be customized, fast delivery.

And Suitable for CNC machining centers, engraving machines, engraving machines and other high-speed machines.

Feature:

1.New cutting edge design, cutting like mud, 0.002mm micro-grain tungsten steel, more stable quality, lower probability of tool breakage

2.Large chip flute, larger capacity. Improve efficiency, use German imported resin grinding wheel, fine grinding, make the cutting edge in the groove smoother, fast chip removal, refuse to stick to the knife, and improve all-round

3.Adopt Swiss bronze nano-coating, 5-layer spraying technology composite coating to increase the hardness, enhance the thermal conductivity of the tool, realize high-efficiency processing, and effectively reduce wear.

4.Long-lasting stability, shank diameter tolerance within 0.005mm, international standard straight shank, the processing process can effectively suppress chattering.

Product detail pictures:

Related Product Guide:

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for Low MOQ for Tapered End Mills - HRC70 carbide tungsten ball milling cutter – MSK , The product will supply to all over the world, such as: Greece, Vietnam, Ottawa, To have much more enterprise. ompanions, we've got updated the item list and seek for optimistic co-operation. Our web-site shows the latest and complete information and facts about our goods list and company. For further acknowledge, our consultant service group in Bulgaria will reply to all of the inquiries and complications immediately. They're going to make their finest effort to meet buyers need. Also we support the delivery of absolutely free samples. Business visits to our business in Bulgaria and factory are generally welcome for a win-win negotiation. Hope to expertise a happy company co-operation perform with you.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!