Hydraulic Machine Vise-Inside

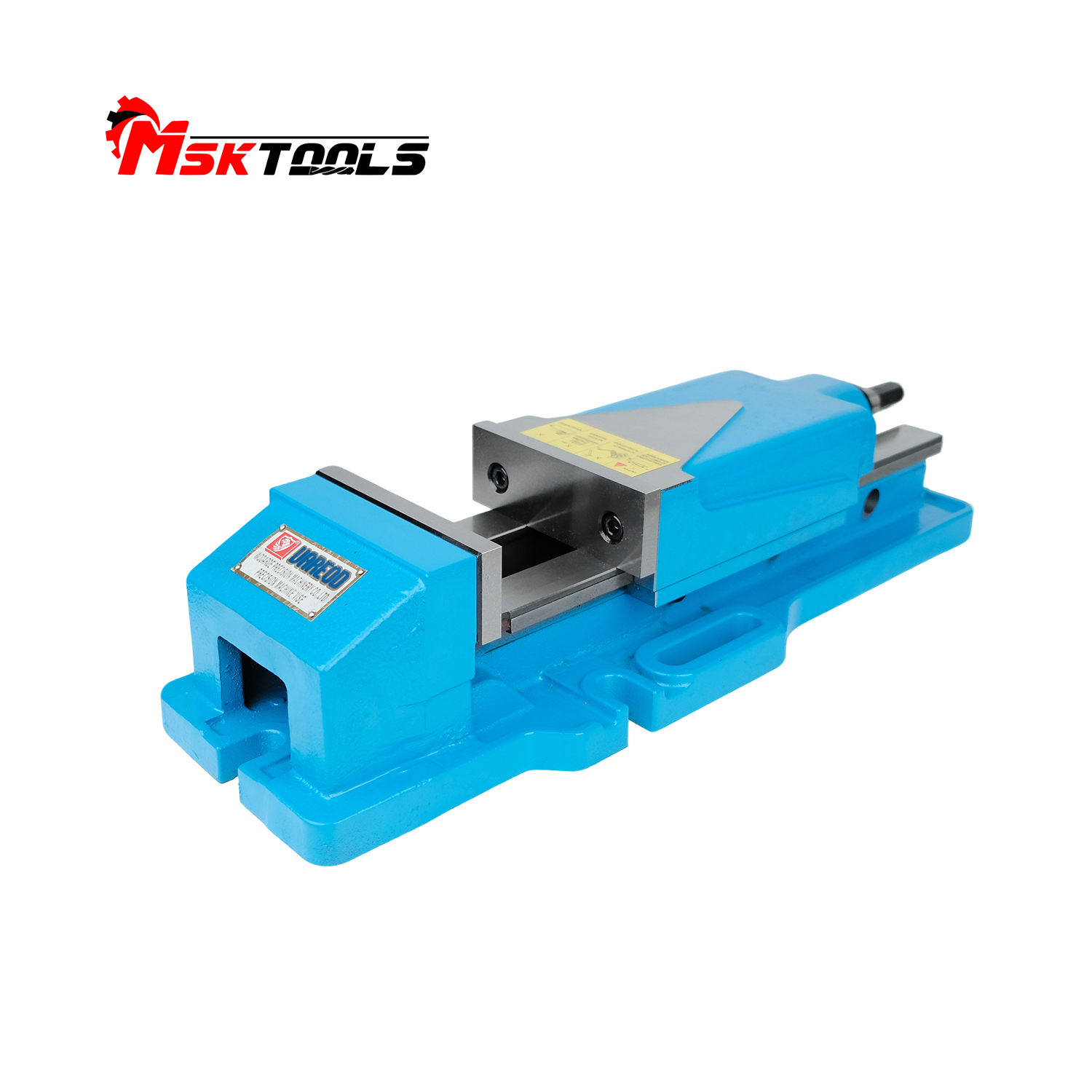

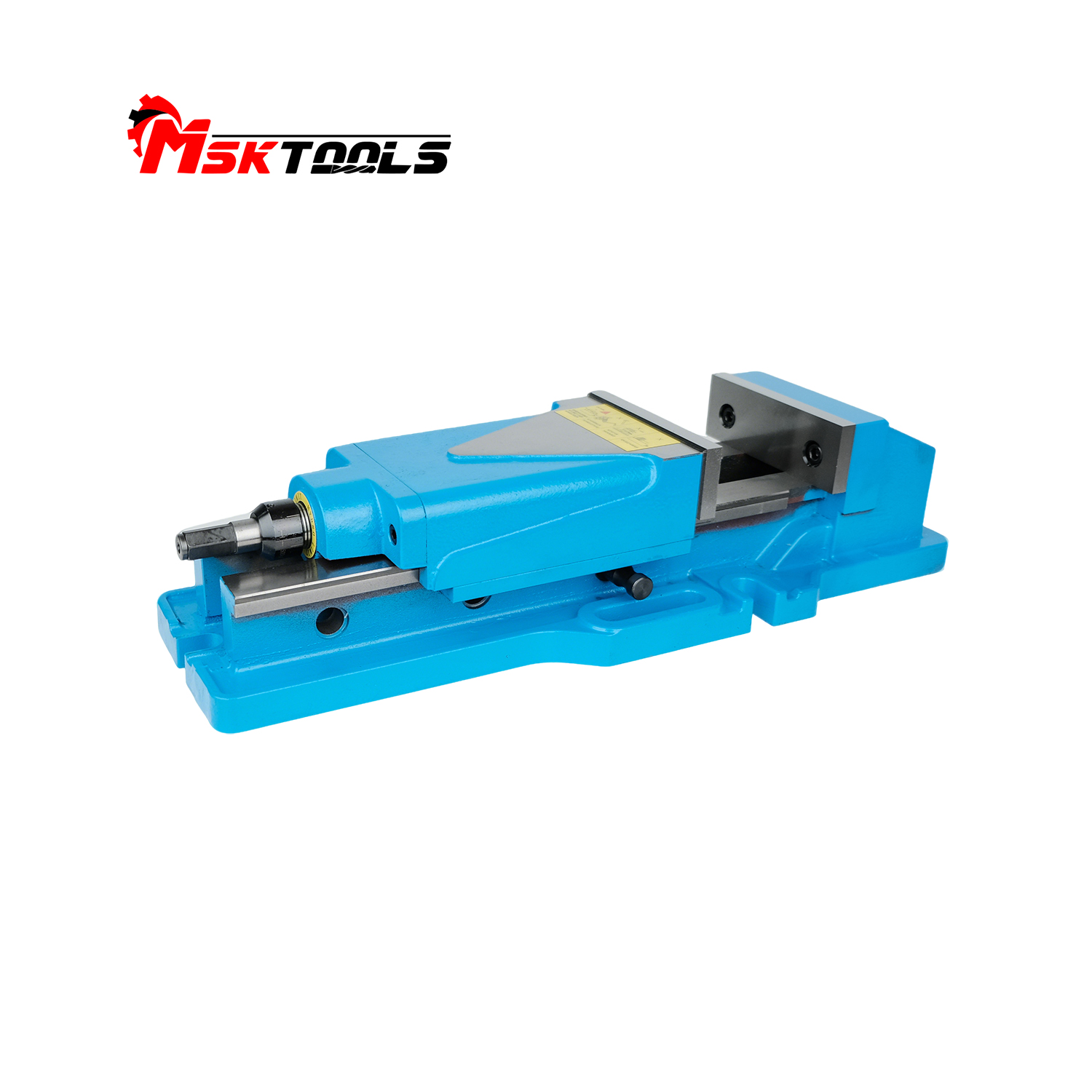

The Hydraulic Machine Vise-Inside features a patented hydraulic cylinder design, providing powerful and stable clamping force to effectively resist vibrations during heavy cutting and ensure machining accuracy. The vise body is made of high-ductility cast iron, with the key slide hardened to HRC42°, combining high wear resistance, high tensile strength, and a large opening for rapid movement. Its structure balances economy and durability, and is easy to maintain, making it ideal for heavy cutting and high-stability machining applications.

This hydraulic pressure-boosting vise features a patented hydraulic cylinder design, providing strong and stable clamping force while effectively suppressing machining vibrations, making it especially suitable for heavy-duty cutting operations. It offers quick pressure release and easy maintenance, is economical, durable, and highly efficient.

The vise body is made of high-ductility cast iron, with the side slides hardened and heat-treated to HRC42°, combining high precision, high wear resistance, and high tensile strength. Furthermore, the vise body has a large opening, allowing for rapid back-and-forth movement of the workpiece, significantly improving operational flexibility.

What customers say about us

FAQ

1. Q: What are the advantages of this hydraulic vise's clamping force? Why is it suitable for heavy cutting?

A: This product uses a patented hydraulic cylinder design, providing greater clamping force and more stable clamping force, effectively resisting vibrations during machining. This allows it to firmly hold the workpiece during heavy cutting, preventing displacement and ensuring machining accuracy and safety.

2. Q: What are the practical benefits of the vise's "wide opening function"?

A: The "wide opening function" refers to the vise's larger opening range. Combined with its rapid back-and-forth movement capability, it significantly reduces clamping and adjustment time, improving work efficiency, and is especially suitable for machining scenarios requiring frequent workpiece changes or adjustments.

3. Q: How is the product's durability and precision guaranteed?

A: The vise body is made of high-ductility cast iron, with a robust structure and high tensile strength. Key sliding parts (side sliders) undergo hardening heat treatment (hardness up to HRC42°), ensuring high wear resistance, high precision retention, and a long service life.

4. Q: Is this hydraulic system easy to maintain?

A: Yes. The patented hydraulic cylinder design combines easy pressure release and maintenance. This design ensures strong and stable clamping force while considering ease of use and low maintenance costs, making it economical and durable.

5. Q: What are the main features and application scenarios of the product?

A: The main features can be summarized as follows: ① Hydraulic booster, large and stable clamping force, vibration resistant; ② Large opening, rapid movement, efficient operation; ③ Hardened treatment of key components, high precision, high wear resistance; ④ High strength and durability of structural materials; ⑤ Easy maintenance of the hydraulic system.

It is ideal for machining environments requiring heavy cutting, high precision, and frequent clamping, such as mold manufacturing and heavy parts processing.

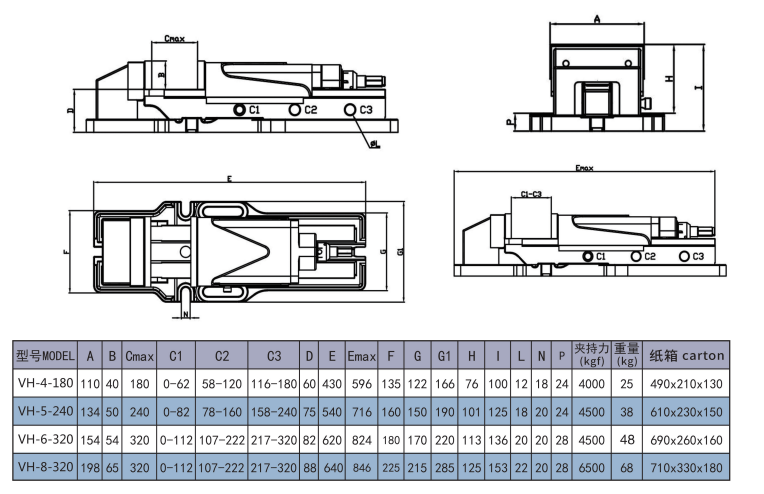

This series of hydraulic pressure vises is designed for heavy-duty cutting and high-precision machining. Utilizing a patented hydraulic cylinder structure, it provides powerful and stable clamping force, effectively suppressing machining vibration. The vise body features a large opening, enabling rapid reciprocating movement while maintaining high efficiency and durability.

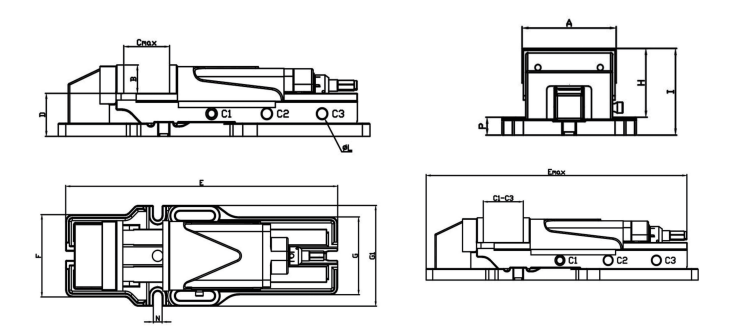

Design and Components

Patented Hydraulic Cylinder: Provides stable clamping force, excellent vibration resistance, and easy pressure release and maintenance.

Vise Body: Constructed from high-ductility cast iron, ensuring a robust and durable structure.

Hardened Slides: Both slides are heat-treated to HRC42°, providing high wear resistance and tensile strength.

Large Opening Mechanism: Supports rapid opening and closing and reciprocating movement, improving operational smoothness.

Functions

High-Pressure Stable Clamping: Hydraulic pressure technology ensures high and consistently stable clamping force, suitable for heavy-duty cutting.

Fast Operation: The large opening design combined with rapid reciprocating movement reduces clamping time.

High Rigidity and Vibration Resistance: Optimized structure and materials effectively absorb vibration, maintaining machining stability.

Easy Pressure Release and Maintenance, Reducing Downtime.

Applications: Suitable for heavy-duty cutting, milling, drilling, and other machining scenarios.

Applied to mold manufacturing, batch processing of parts, and high-load machine tool support.

Suitable for production lines requiring frequent workpiece changes and prioritizing both efficiency and precision.

Precision Machining: Hardened slider treatment and high-precision manufacturing processes ensure the vise maintains micron-level repeatability over the long term.

High wear-resistant design extends service life, maintaining machining consistency even under high-frequency use.

High structural rigidity effectively transmits cutting forces, preventing precision loss due to workpiece displacement or vibration.

Challenges and Considerations: Under extreme heavy-duty cutting conditions, ensuring the hydraulic system's sealing and pressure stability is crucial.

During installation, attention must be paid to the accuracy of the base plane and the even distribution of clamping force to maximize efficiency.

Regularly inspect the hydraulic circuit and slider wear to maintain long-term performance.

This hydraulic booster vise integrates patented hydraulic technology, a high-ductility cast iron structure, and a hardened slider design, providing powerful clamping force and vibration resistance while balancing operational efficiency and ease of maintenance. Its high rigidity, high wear resistance and high precision make it a reliable choice for heavy cutting and precision machining, which can significantly improve machining stability, efficiency and workpiece quality.