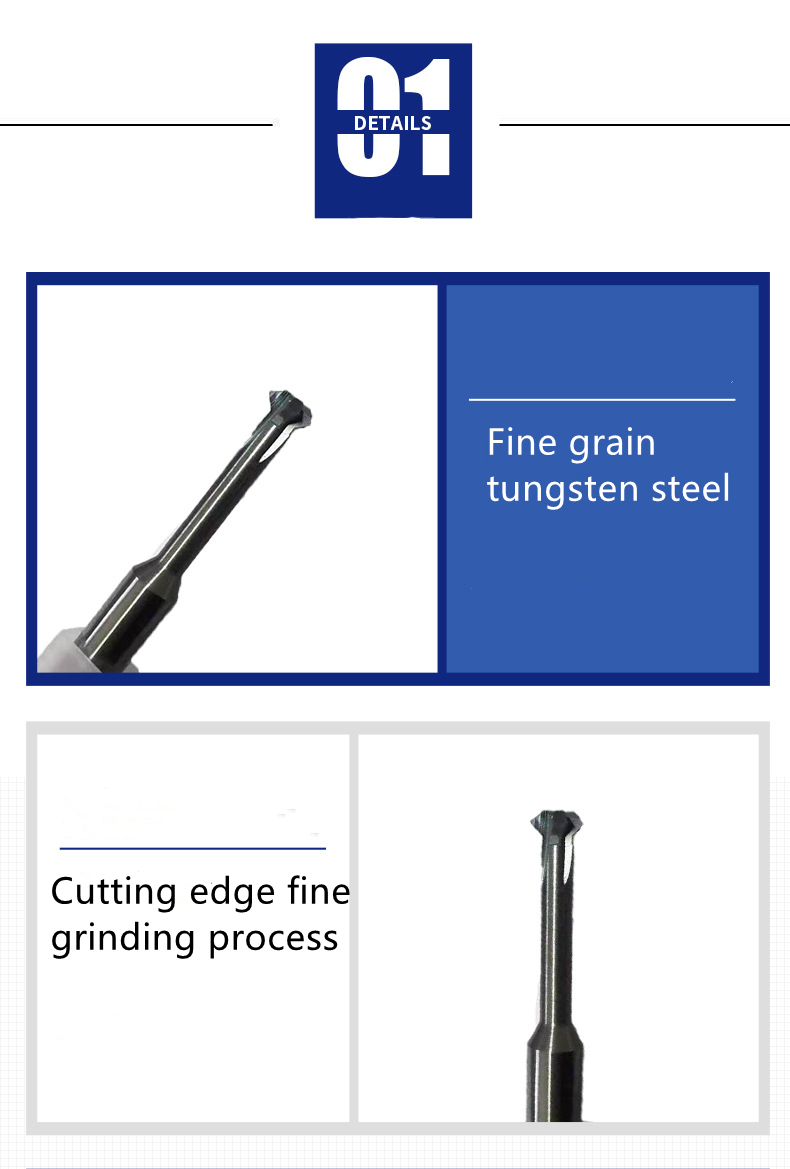

High Quality Surfacing End Mill - Carbide Chamfer End Mill for deburring and chamfering – MSK

High Quality Surfacing End Mill - Carbide Chamfer End Mill for deburring and chamfering – MSK Detail:

Inner hole chamfering knife is also called chamfering device. It has a wide range of applications, not only suitable for chamfering of ordinary machined parts, but also for chamfering and deburring of precision difficult-to-chamfer machining parts.

Chamfering cutters are assembled on milling machines, drilling machines, planers, chamfering machines and other machine tools for processing 60-degree or 90-degree chamfering and taper holes, and chamfering corners of workpieces, and they belong to end mills.

Advantage:

1) Convenient clamping, no special clamping head is required, almost all rotating processing equipment and tools can be used, such as: drilling machines, milling machines, lathes, machining centers, power tools, etc.

2) Wide range of application, not only suitable for chamfering of ordinary machined parts, but also suitable for chamfering and deburring of precision difficult to chamfer parts. Such as: aviation, military industry, automobile industry oil, gas, electric valve, engine block, cylinder, sphere through hole, inner wall hole.

3) High working efficiency, fast processing operation can be realized due to its own elastic strength, no matter manual free operation or automatic timing feed can obtain good processing results.

4) It can be repeated grinding, suitable for mass production, and can effectively reduce costs.

5) Use this product before tapping; using it after tapping may damage the threads.

About Us

Founded in 2015, MSK (Tianjin) International Trading CO.,Ltd has grown continuously and passed Rheinland ISO 9001 authentication.

With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end, professional and efficient CNC tool.

Our specialty is the design and manufacturing of all kinds of solid carbide cutting tools: End mills, drills, reamers, taps and special tools.

Our business philosophy is to provide our customers with comprehensive solutions that improve machining operations, increase productivity, and reduce costs. Service + Quality + Performance.

Our Consultancy team also offers production know-how, with a range of physical and digital solutions to help our customers navigate safely into the future of industry 4.0.

take a practical approach to applying high levels of metal cutting competence to overcoming customers’ challenges. Relationships built on trust and respect are vital to our success. We work closely with customers to understand their needs.

For more in-depth information on any particular area of our company, please explore our site or use the contact us section to reach out to our team directly.

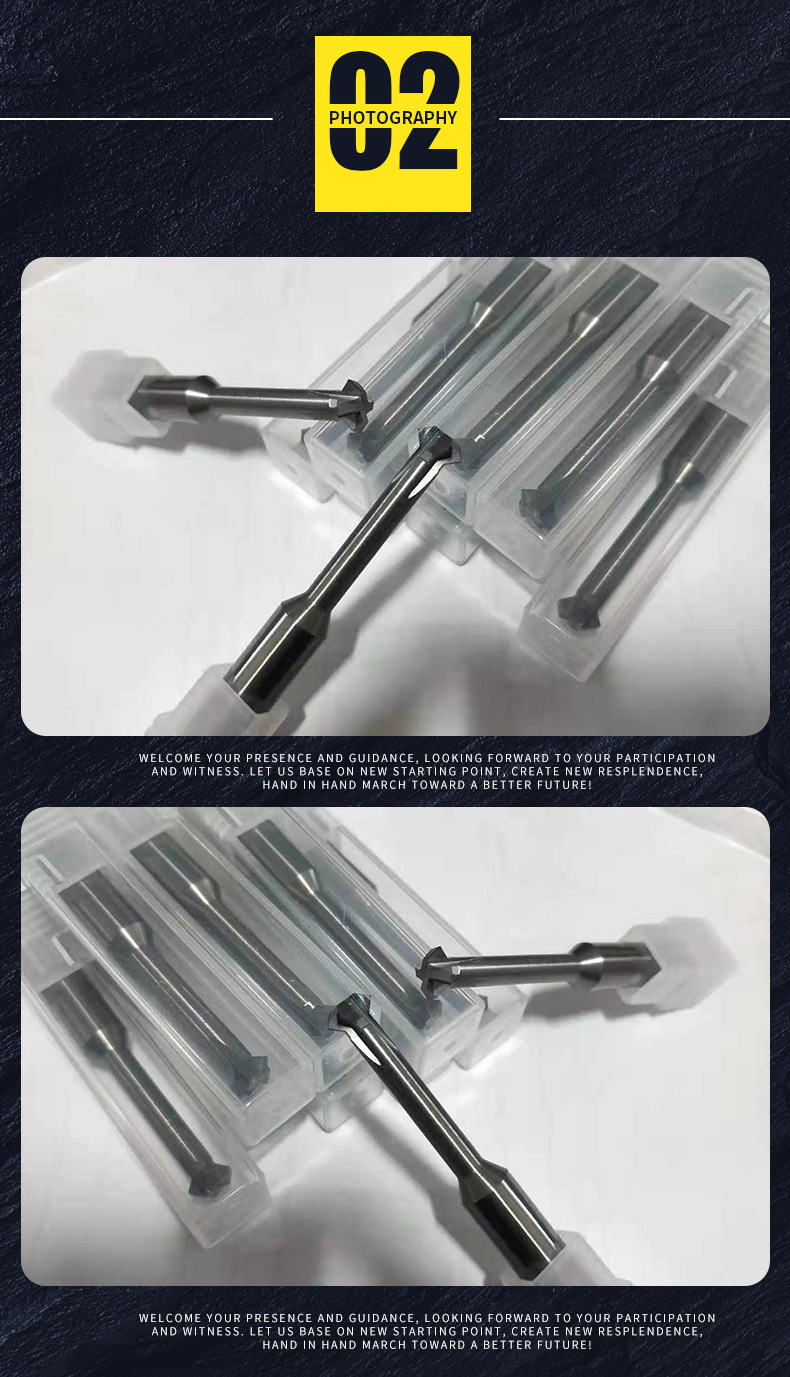

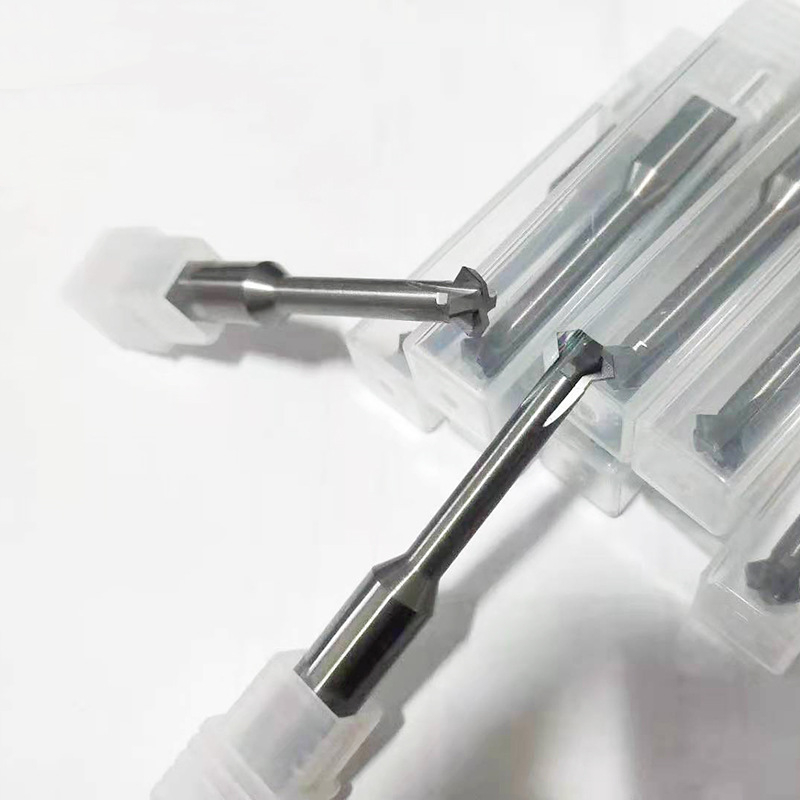

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for High Quality Surfacing End Mill - Carbide Chamfer End Mill for deburring and chamfering – MSK , The product will supply to all over the world, such as: Rio de Janeiro, Paris, Brisbane, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to provide customers with high quality products, provide high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!