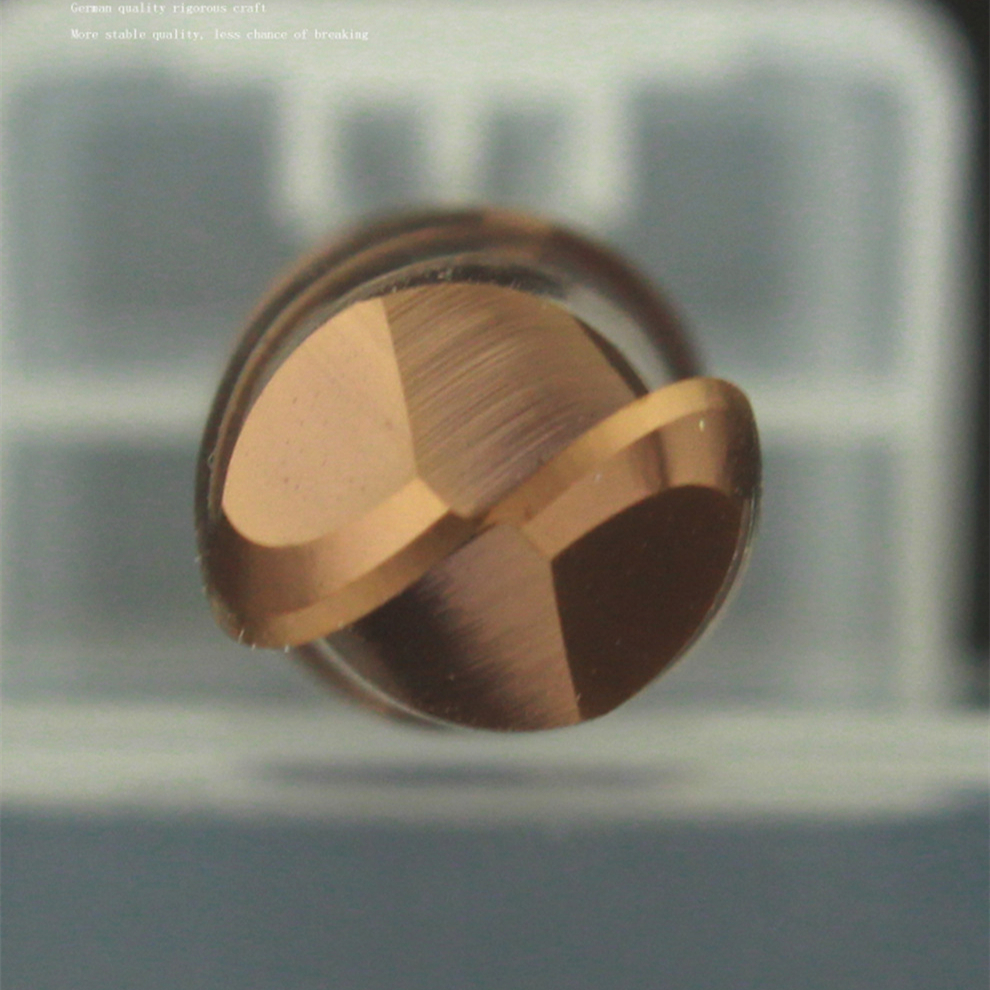

Excellent quality Ball Mill Bit - HRC70 Yellow Nano 2 Flutes End Mill – MSK

Excellent quality Ball Mill Bit - HRC70 Yellow Nano 2 Flutes End Mill – MSK Detail:

| Product Name | HRC70 Yellow Nano 2 Flutes End Mill | Material | Tungsten Steel |

| Workpiece Material | High manganese steel, hardened steel, cast iron, stainless steel, 45# steel, quenched and tempered steel and other difficult-to-process materials | Numerical Control | CNC machining centers, engraving machines, engraving machines and other high-speed machines. |

| Transport Package | Box | Flute | 2 |

| Coating | Yes for steel, no for aluminium | Hardness | HRC70 |

|

Number of flutes |

2 |

Material |

Aluminum alloy / copper alloy / graphite / resin |

|

Brand |

MSK |

Flute Diameter D(mm) |

1-20 |

|

Coating |

No |

Type |

flat surface |

|

Package |

Box |

Length |

50-100 |

This milling cutter adopts high-hardness bronze nano-coating, specially processing HRC70 hardness workpiece material, so it is called super-hard tungsten steel ball-end milling cutter. Non-standard products, need to be customized, fast delivery.

And Suitable for CNC machining centers, engraving machines, engraving machines and other high-speed machines.

| Product Name | HRC70 Yellow Nano 2 Flutes End Mill | Material | Tungsten Steel |

| Workpiece Material | High manganese steel, hardened steel, cast iron, stainless steel, 45# steel, quenched and tempered steel and other difficult-to-process materials | Numerical Control | CNC machining centers, engraving machines, engraving machines and other high-speed machines. |

| Transport Package | Box | Flute | 2 |

| Coating | Yes for steel, no for aluminium | Hardness | HRC70 |

Feature:

1.New cutting edge design, cutting like mud, 0.002mm micro-grain tungsten steel, more stable quality, lower probability of tool breakage

2.Large chip flute, larger capacity. Improve efficiency, use German imported resin grinding wheel, fine grinding, make the cutting edge in the groove smoother, fast chip removal, refuse to stick to the knife, and improve all-round

3.Adopt Swiss bronze nano-coating, 5-layer spraying technology composite coating to increase the hardness, enhance the thermal conductivity of the tool, realize high-efficiency processing, and effectively reduce wear.

4.Long-lasting stability, shank diameter tolerance within 0.005mm, international standard straight shank, the processing process can effectively suppress chattering.

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary goal. We uphold a consistent level of professionalism, quality, credibility and service for Excellent quality Ball Mill Bit - HRC70 Yellow Nano 2 Flutes End Mill – MSK , The product will supply to all over the world, such as: United States, Azerbaijan, Somalia, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.