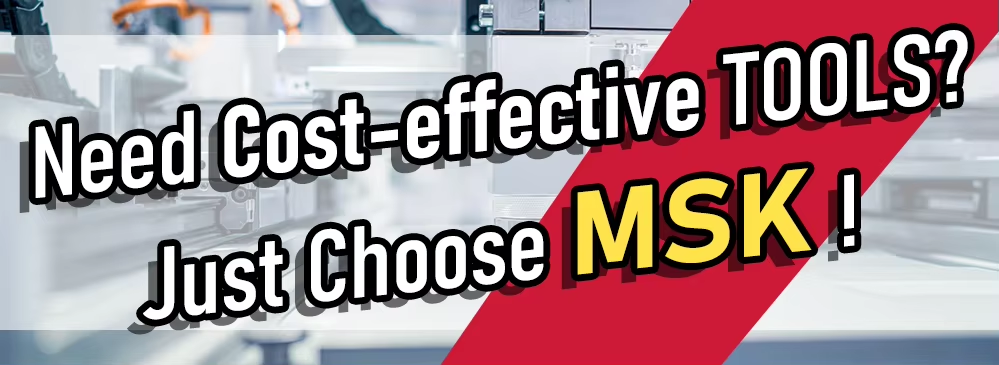

CNC Internal Turning Toolholders – 95° Anti-vibration Carbide Shank

1. Alloy material, high hardness and durability

2. Tight fit, blade does not chipping

3. Quenched and hardened, high strength and shock resistance

4. Effective Boring Depth

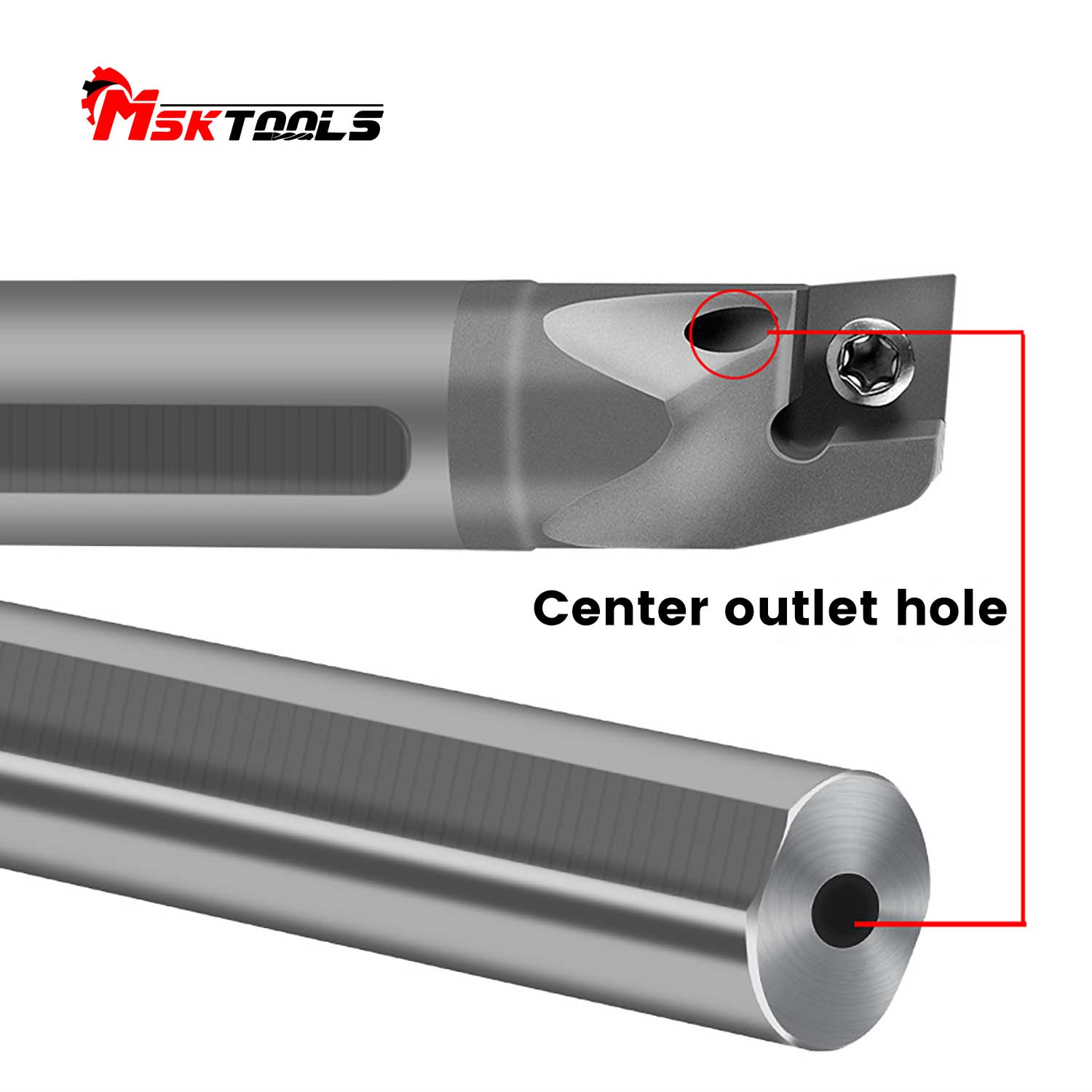

5. Center holes, static grinding

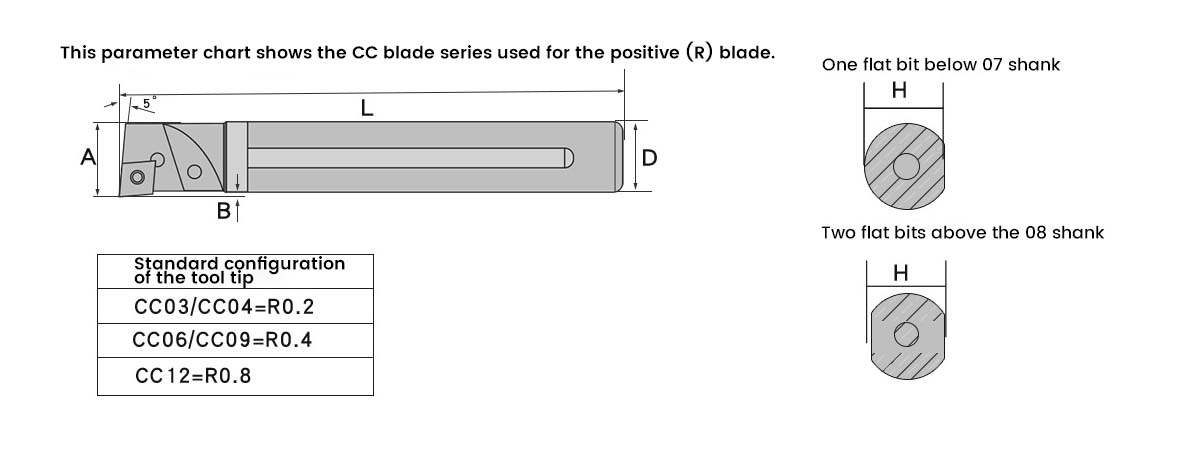

Cutting groove selection

| Product Parameters | |||

| Turning tools are used for milling processing with high vibration resistance, which can reduce the processing cost | |||

| Brand | MSK | Accessories | Plum screws, plum wrenches |

| Cutting tool shank structure | Solid powerful type/center out of the water type | ||

| Product Name | Anti vibration bore cutter shanks | Material | Cemented Carbide |

| Main features | High-performance replaceable inserts, the use of shock-resistant material alloy steel can effectively suppress vibration, according to the machining function of the tool handle through computer-aided design to obtain the shape of the tool. The toolholder is designed in a discarded way to reduce machining costs. | ||

| Model Specifications | Shank diameter | Overall length | Size | Depth of blade | Machining | Screw wrench | Blade type |

| D | L | A | B | Hole Diameter | T | E | |

| EO4G-SCLCRO3 | 04 | 90 | 4.5 | 0.5 | 4.8 | M1.6-T6 | CC--03S |

| EO5H-SCLCRO3 | 05 | 100 | 5.5 | 0.5 | 5.8 | ||

| EO6J-SCLCR03 | 06 | 110 | 6.5 | 0.5 | 6.8 | ||

| E06J-SCLCR04 | 06 | 110 | 6.5 | 0.5 | 6.8 | M2.0-T6 | CC--04T |

| EO7K-SCLCRO4 | 07 | 125 | 7.5 | 0.5 | 7.8 | ||

| E08K-SCLCR04 | 08 | 125 | 8.5 | 0.5 | 8.8 | ||

| E08K-SCLCRO6 | 08 | 125 | 9 | 1 | 10 | M2.5-T8 | CC--0602 |

| E10K-SCLCR06 | 10 | 125 | 11 | 1 | 12 | ||

| E10M-SCLCR06 | 10 | 150 | 11 | 1 | 12 | ||

| E12Q-SCLCR06 | 12 | 180 | 13 | 1 | 14 | ||

| E14Q-SCLCR06 | 14 | 180 | 15 | 1 | 16 | ||

| E16R-SCLCR09 | 16 | 200 | 17 | 1 | 18 | M3.5-T15 | CC--09T3 |

| E18S-SCLCRO9 | 18 | 250 | 19 | 1 | 20 | ||

| E2OR-SCLCRO9 | 20 | 200 | 21 | 1 | 22 | M4.0-T15 | CC--09T3 |

| E20S-SCLCRO9 | 20 | 250 | 21 | 1 | 22 | ||

| E25T-SCLCR09 | 25 | 300 | 27 | 2 | 29 | ||

| E32U-SCLCR12 | 32 | 350 | 34 | 4 | 38 | M5.0-T20 | CC--1204 |

| CD solid low resistance toolholder | |||||||

| C05H-SCLDR04T | 5 | 100 | 5.5 | 0.5 | 6 | M2-T6 | CD-04T0 |

| C06J-SCLDR04T | 6 | 110 | 6.5 | 0.5 | 7 | ||

| C07K-SCLDR04T | 7 | 125 | 7.5 | 0.5 | 8 | ||

| C08K-SCLDR04T | 8 | 125 | 9 | 1 | 10 | ||

| C10M-SCLDR04T | 10 | 150 | 11 | 1 | 12 | ||

| C12Q-SCLDR06T | 12 | 180 | 13 | 1 | 14 | M2.5-T8 | CD--06T0 |

| C16R-SCLDR06T | 16 | 200 | 17 | 1 | 18 | ||

The knife pole is super shock-resistant, sturdy and durable, with our upgraded blade, more wear-resistant

Adopting laser laser treatment, printing scale product model, no colour loss, wear-resisting

High-performance material diamond-shaped groove, not easy to jam, smooth cutting

Bottom design for good compatibility and tighter clamping without slipping

Why Choose Us

Factory Profile

About Us

FAQ

Q1: who are we?

A1: Founded in 2015, MSK (Tianjin) Cutting Technology CO.Ltd has grown continuously and passed Rheinland ISO 9001

authentication.With German SACCKE high-end five-axis grinding centers, German ZOLLER six-axis tool inspection center, Taiwan PALMARY machine and other international advanced manufacturing equipment, we are committed to producing high-end,professional and efficient CNC tool.

Q2: Are you trading company or manufacturer?

A2: We are the factory of carbide tools.

Q3: Can you send products to our Forwarder in China?

A3: Yes,if you have Forwarder in China,we will glad to send products to him/her.Q4: What terms of payment are acceptable?

A4: Normally we accept T/T.

Q5: Do you accept OEM orders?

A5: Yes, OEM and customization are available, and we also provide label printing service.

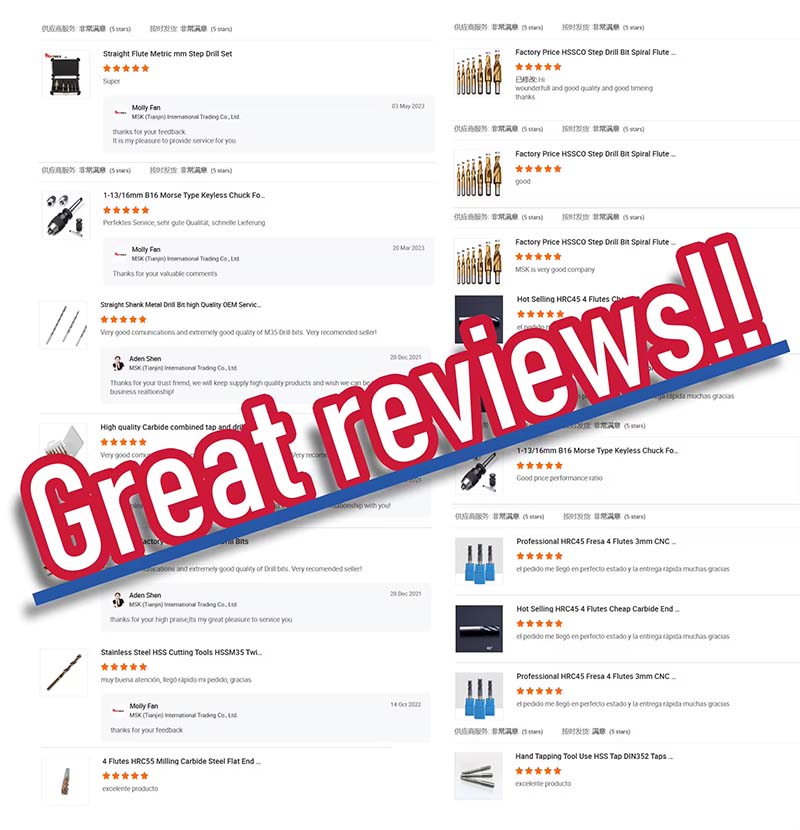

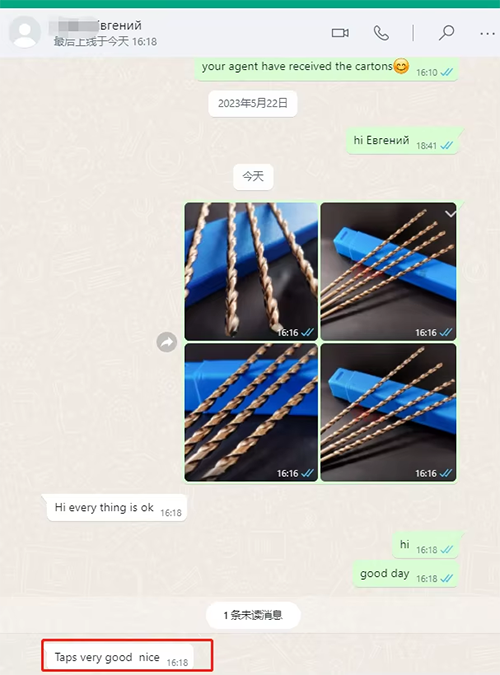

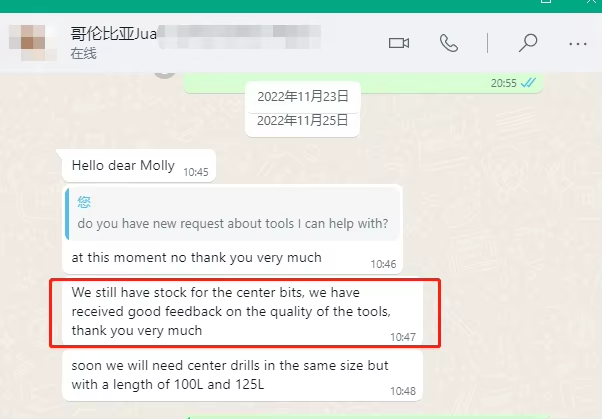

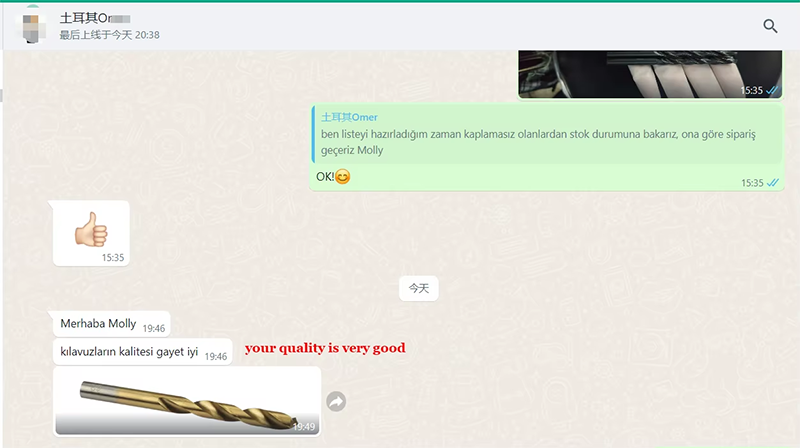

Q6: Why should you choose us?

A6:1) Cost control - purchasing high-quality products at an appropriate price.

2) Quick response - within 48 hours, professional personnel will provide you with a quote and address your concerns.

3) High quality - The company always proves with sincere intention that the products it provides are 100% high-quality.

4) After sales service and technical guidance - The company provides after-sales service and technical guidance according to customer requirements and needs.