Carbide T-slot End Mill Cutter Fresas Para Ranura Cuadros Tipo T

INCAZELO YOMKHIQIZO

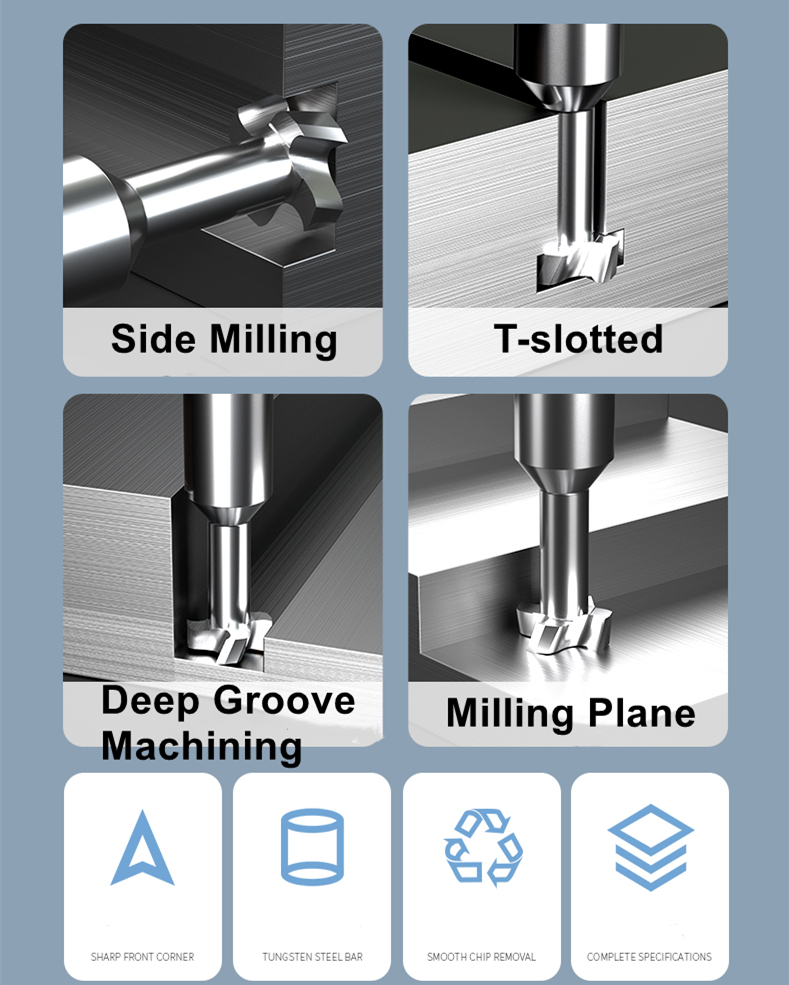

Ukuze kugaywe i-T-slot esebenza kahle kakhulu enamazinga aphezulu okuphakelayo kanye nokujula kokusikwa. Ifanele futhi imishini yokuhlikihla phansi kwe-groove ekusetshenzisweni kokugaya okujikelezayo. Ama-inserts afakwe ngendlela ye-tangential aqinisekisa ukususwa kwe-chip okuhle kakhulu kuhlanganiswe nokusebenza okuphezulu ngaso sonke isikhathi.

Umklamo okhethekile we-helical groove ephezulu, kanye nomklamo ofanele wokugwema umoya, kwenza kube nendawo enkulu yokususa ama-chip, okwenza ukususwa kwama-chip kube lula ngesikhathi sokusika.

Izici eziyinhloko:

Iyithuluzi elikhethekile lokucubungula ama-T-slots. Ngemva kokuba imigoqo eqondile isigayiwe, ama-T-slots anokunemba okudingekayo angagayiwa ngesikhathi esisodwa. Unqenqema lokugcina lwesikhiphi sokugaya lune-engeli yokusika efanele, ukunemba okuphezulu kanye nokucwebezela.

Umsiki wokugaya we-T-slot (owaziwa nangokuthi umsiki wokugaya we-T-slot, umsiki wokugaya we-waist slot)

Izici zomsiki wokugaya we-T-slot: imigoqo ehlukahlukene yesikwele, imigoqo eyindilinga, imigoqo enomumo okhethekile, njll., ithuthukisa kakhulu ukusebenza kahle kokucubungula ekukhiqizeni;

Izinto zokusika i-T-slot milling: i-carbide, i-V-welding, i-powder metallurgy, ama-welding alloy inserts, njll.;

Ukumbozwa kwesikhiphi sokugaya i-T-slot: ukumbozwa kungakhethwa, futhi ukumbozwa kuchazwe ngokwezimo zokusebenza zezinto zomkhiqizo;

Izimboni eziyinhloko zokusika i-T-slot milling: izingxenye zezimoto, izinto zikagesi, ezokwelapha, ezindiza, imishini yokwakha kanye neminye imikhakha eminingi;

Izinto zokucubungula i-T-slot milling cutter: izinsimbi ezingezona i-ferrous (i-aluminium alloy, ithusi), insimbi ephonswe ngensimbi, insimbi ye-alloy, insimbi ye-carbon ephansi, insimbi enobunzima obuphezulu, insimbi engagqwali, kanye nezinto ezahlukahlukene okunzima ukuzisebenzisa ngomshini;

ISINCOMO SOKUSENZISWA EZINDAWENI ZOKUSEBENZA

1. Kukhethwa imigoqo yensimbi ye-tungsten engenisiwe, enobulukhuni obuphezulu kanye nokumelana nokuguguleka, imimese ebukhali futhi engelula ukuyifinyeza, kanye nempilo yenkonzo ende

2. Umklamo womphetho wokusika, ubuciko obuyindilinga, ukukhethwa kwezinto ezinhle kakhulu, kanye nomklamo omkhulu wokusika kuthuthukisa kakhulu ukushelela.

3. Inkemba ebukhali. Unqenqema lokusika lubukhali, okwenza ukusika kube bushelelezi, futhi ukwakheka konqenqema lokusika kungathuthukisa ngempumelelo ukuzinza kokucubungula kanye nekhwalithi yobuso.

4. Umklamo we-chamfer, usayizi we-chamfer ojwayelekile, i-chamfer engama-degree angu-45, i-contour eyindilinga futhi ebushelelezi, okwenza kube lula ukuyifaka.

| Umkhiqizo | I-MSK | Izinto | Insimbi edayiwe; insimbi ephothiwe; insimbi yekhabhoni; insimbi ye-alloy |

| Igama Lomkhiqizo | Umsiki Wokusika I-T-slot End Mill | Iphakheji | Ibhokisi Lepulasitiki |

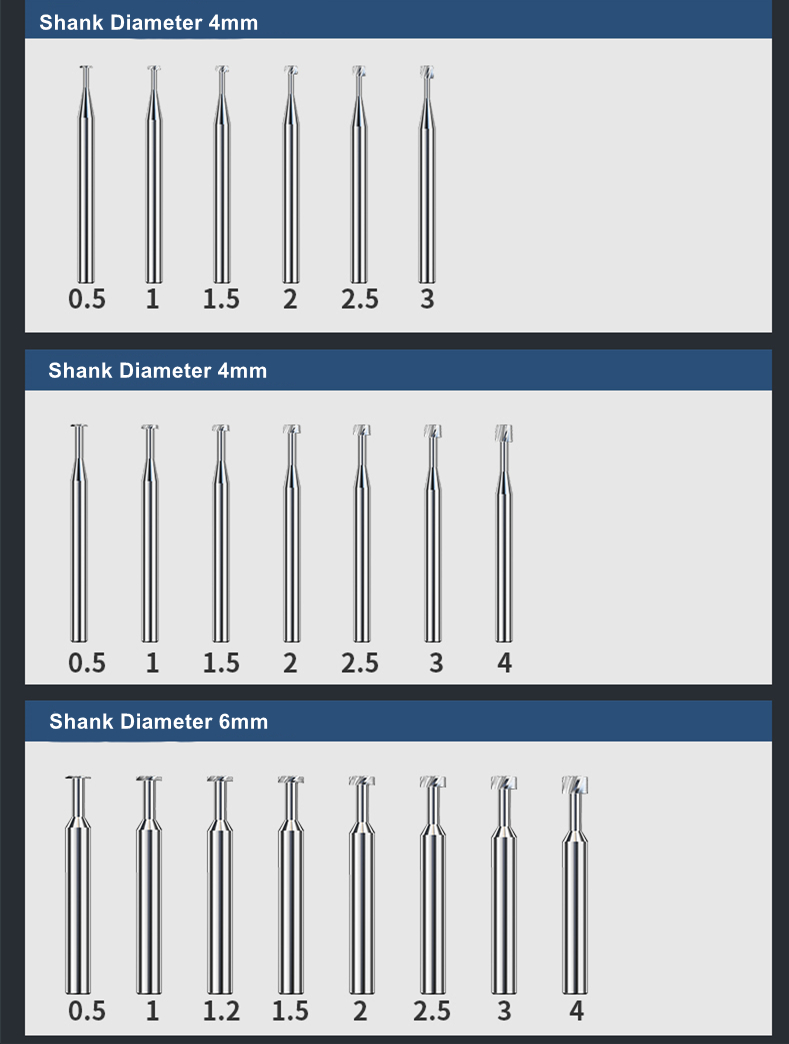

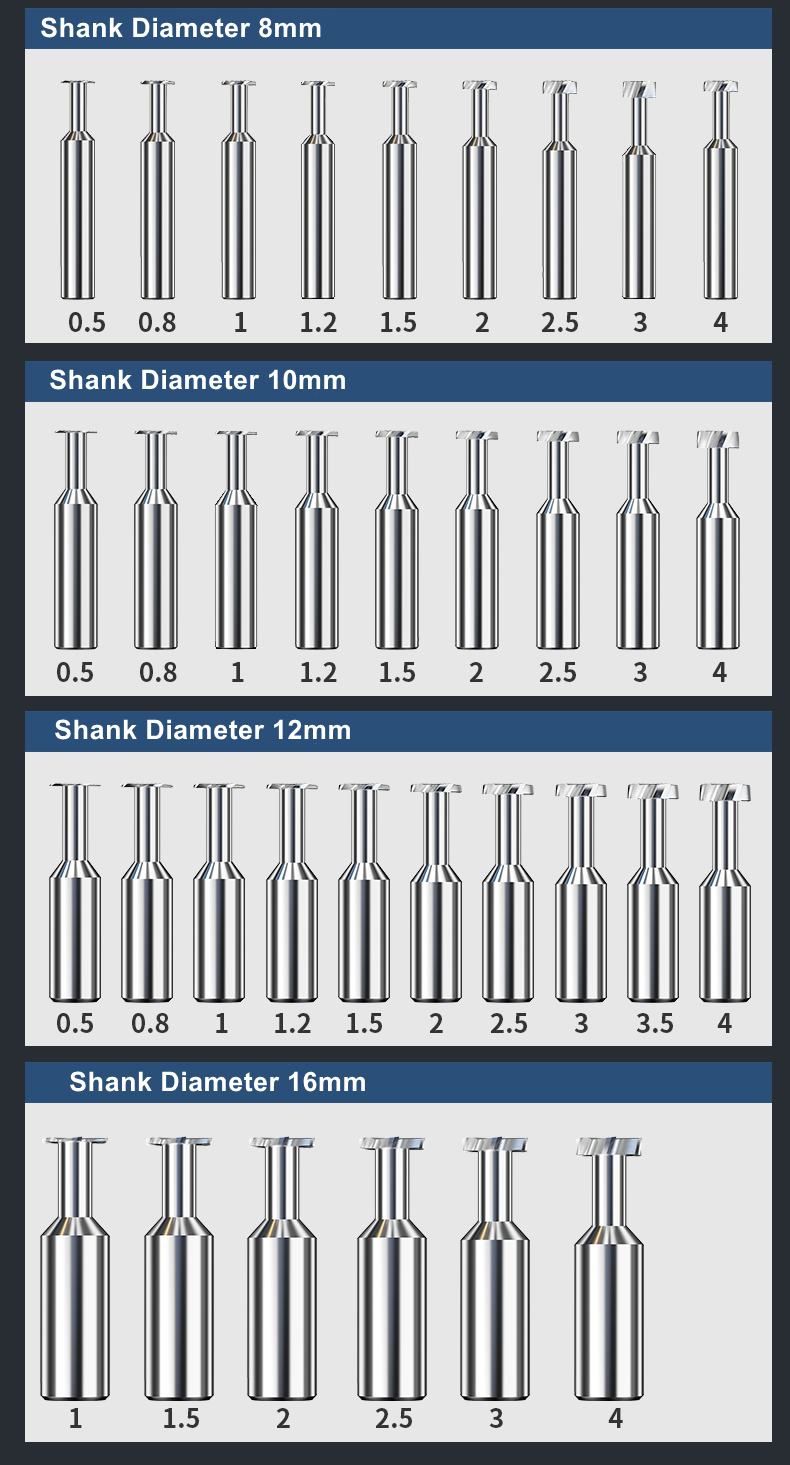

Izithombe Eziningiliziwe