Carbide T-slot End Mill Cutter Fresas Para Ranura Cuadros Tipo T

INGCACISO YEMVELISO

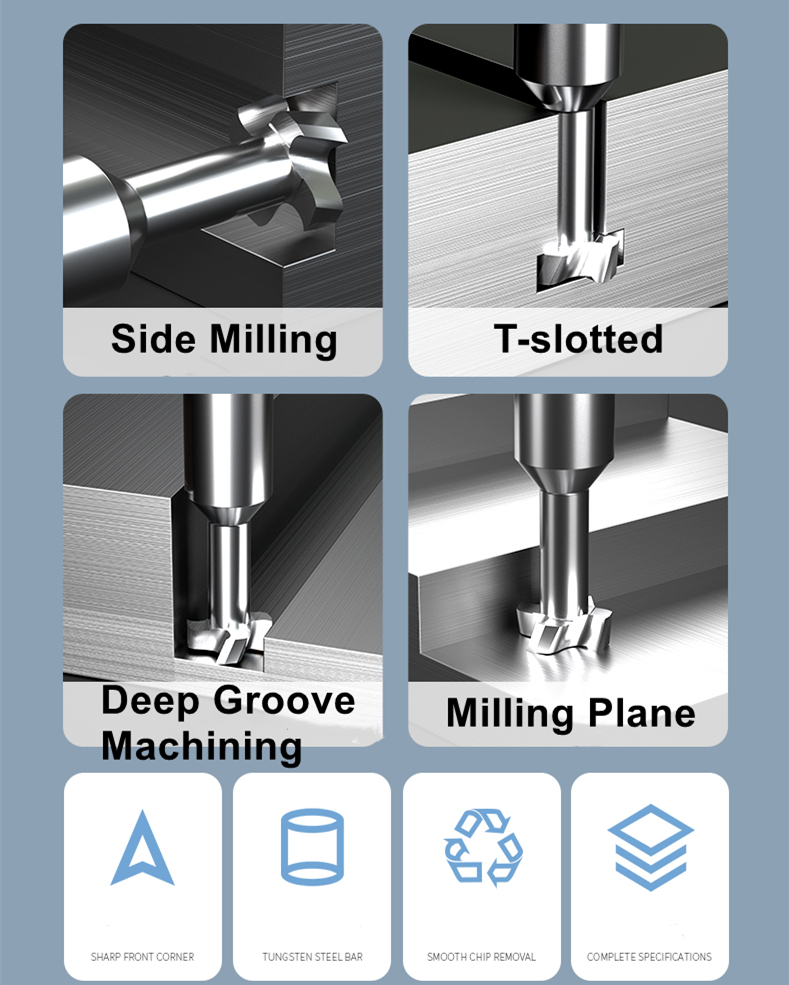

Kwi-T-slot milling esebenza kakuhle kakhulu enezinga eliphezulu lokutya kunye nobunzulu bokusika. Ikwafanelekile nakwi-groove bottom machining kwizicelo ze-circular milling. I-tangentially efakwe i-indexable ifaka isiqinisekiso sokususwa kwee-chip ezifanelekileyo kunye nokusebenza okuphezulu ngamaxesha onke.

Uyilo olukhethekileyo lwe-helical groove ephezulu, kunye noyilo olufanelekileyo lokuphepha umoya, lwenza ukuba ibe nendawo enkulu yokususa iitshiphusi, nto leyo eyenza ukususwa kweetshiphusi kube lula ngexesha lokusika.

Iimpawu eziphambili:

Sisixhobo esikhethekileyo sokucubungula ii-T-slots. Emva kokuba imingxunya ethe tye igutyungelwe, ii-T-slots ezinobunono obufunekayo zinokugutyungelwa ngexesha elinye. Umphetho wesiphelo se-milling cutter une-engile yokusika efanelekileyo, ubunono obuphezulu kunye nokuqaqamba.

Umsiki wokugaya i-T-slot (okwaziwa ngokuba ngumsiki wokugaya i-T-slot, umsiki wokugaya i-waist slot)

Iimpawu ze-T-slot milling cutter: ii-grooves ezahlukeneyo zesikwere, ii-grooves ezijikelezayo, ii-grooves ezinemilo ekhethekileyo, njl.njl., ziphucula kakhulu ukusebenza kakuhle kokucubungula kwimveliso;

Izinto zokusika i-T-slot milling: i-carbide, i-V-welding, i-powder metallurgy, i-welding alloy inserts, njl.njl.;

Ukugqunywa kwe-T-slot milling cutter: ukugqunywa akunyanzelekanga, kwaye ukugqunywa kuchazwe ngokweemeko zokusebenza zezinto zemveliso;

Amashishini aphambili e-T-slot milling cutter: iinxalenye zeemoto, izixhobo ze-elektroniki, ezonyango, ezomoya, oomatshini bokwakha kunye nezinye iinkalo ezininzi;

Izixhobo zokucubungula umsiki we-T-slot milling: iintsimbi ezingezizo i-ferrous (i-aluminium alloy, i-copper), i-cast iron, i-alloy steel, intsimbi enekhabhoni ephantsi, intsimbi enobunzima obuphezulu, intsimbi engagqwaliyo, kunye nezinye izinto ezinzima ukusetyenzwa ngomatshini;

INGCEBISO YOKUSETYENZISWA KWII-WORKSHOP

1. Kukhethwa iibha zentsimbi ye-tungsten ezingenisiweyo, ezinobunzima obuphezulu kunye nokumelana nokuguguleka, iimela ezibukhali nezingelula ukuzifinyeza, kunye nobomi benkonzo ende

2. Uyilo lomphetho wokusika, ubuchule obujikelezileyo, ukhetho oluhle kakhulu lwezinto, kunye noyilo olukhulu lokusika luphucula kakhulu ubugudi.

3. Incakuba ebukhali. Umphetho wokusika ubukhali, okwenza ukusika kube bushelelezi, kwaye uyilo lomgca wokusika oluchasene nokungcangcazela lunokuphucula ngokufanelekileyo uzinzo lokucubungula kunye nomgangatho womphezulu.

4. Uyilo lwe-chamfer, ubungakanani be-chamfer eqhelekileyo, i-chamfer engama-45 degrees, ijikelezileyo kwaye igudileyo, okwenza kube lula ukuyifaka.

| Uphawu | I-MSK | Izinto eziphathekayo | Isinyithi esitshisiweyo; isinyithi esityhidiweyo; isinyithi sekhabhoni; isinyithi se-alloy |

| Igama lemveliso | Umsiki we-T-slot End Mill | Iphakheji | Ibhokisi yeplastiki |

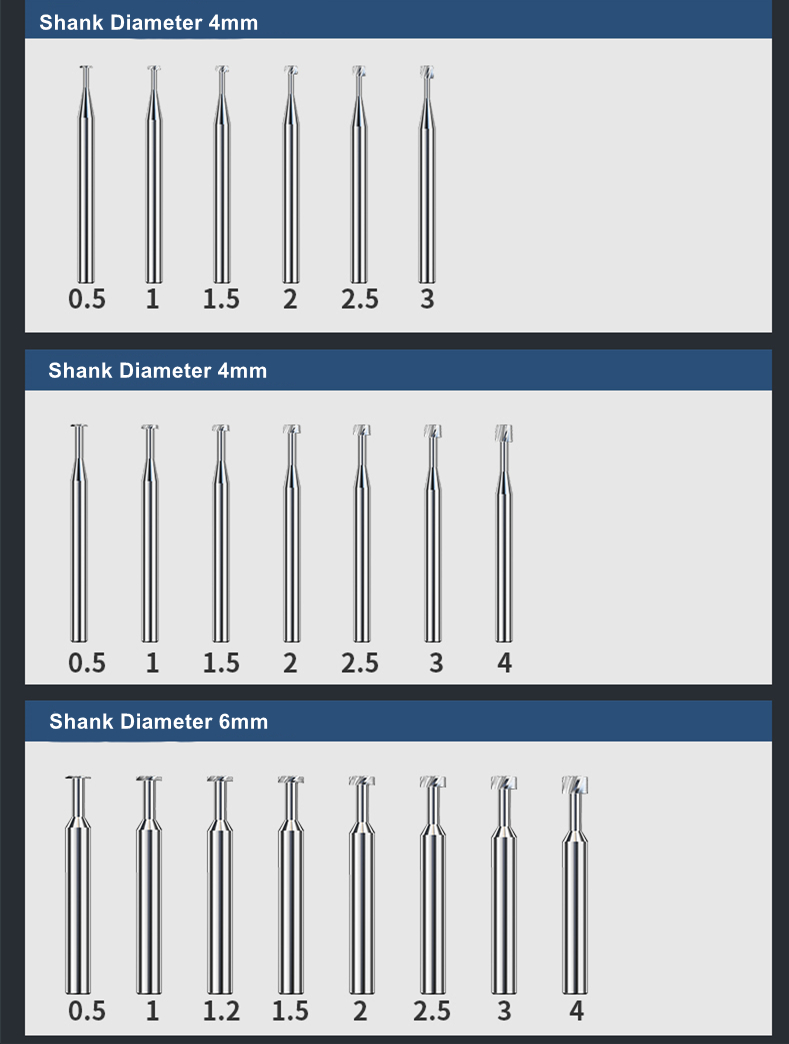

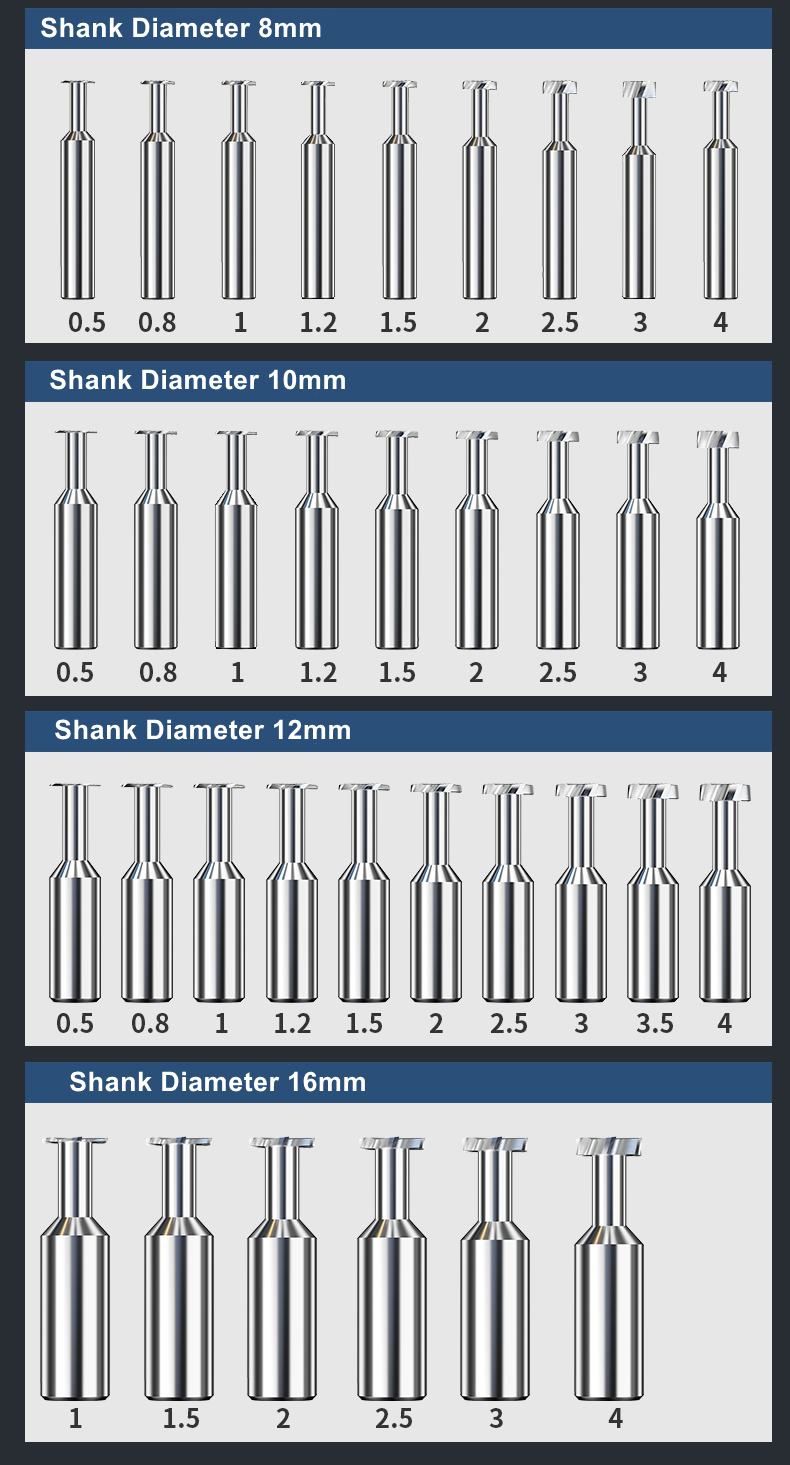

Imifanekiso eneenkcukacha