Iindaba zeMveliso

-

Ukusetyenziswa ngokuchanekileyo kwee-impact drill bits

(1) Ngaphambi kokuba usebenze, qiniseka ukuba ujonga ukuba umbane uyahambelana na nombane olinganisiweyo we-220V ovunyelwene ngawo kwisixhobo sombane, ukuze kuthintelwe ukudibanisa ngempazamo umbane we-380V. (2) Ngaphambi kokuba usebenzise i-impact drill, nceda ujonge ngononophelo i-insulation protec...Funda ngokugqithisileyo -

Iingenelo zeebhithi zokubhola zentsimbi ye-tungsten zokubhola izinto zokusebenza zentsimbi engagqwaliyo.

1. I-tungsten steel iyamelana nokuguguleka, ifana ne-drill bit yesibini emva kwe-PCD, inokumelana nokuguguleka okuphezulu kwaye ifanelekile kakhulu ekucubunguleni izinto zokusebenza zentsimbi/zentsimbi engatyiwayo. 2. Ukumelana nobushushu obuphezulu, kulula ukuvelisa ubushushu obuphezulu xa ugqobhoza kwiziko lomatshini we-CNC okanye kwindawo yokugqobhoza...Funda ngokugqithisileyo -

Inkcazo, iingenelo kunye nokusetyenziswa okuphambili kweetephu zesikhonkwane

Iimpompo ze-Spiral point taps zikwaziwa ngokuba zii-tip taps kunye nee-edge taps kwishishini le-machining. Eyona nto ibalulekileyo kwisakhiwo se-screw-point tap yi-screw-point groove ethambekileyo neyi-positive-taper ekwicala elingaphambili, egoba ukusika ngexesha lokusika kunye ...Funda ngokugqithisileyo -

Ungayikhetha njani i-drill ngesandla?

I-drill yombane ngesandla yeyona incinci kakhulu phakathi kwazo zonke ii-drill zombane, kwaye kunokuthiwa yanele ukuhlangabezana neemfuno zemihla ngemihla zosapho. Ngokubanzi incinci ngobukhulu, ithatha indawo encinci, kwaye ilungele ukugcinwa nokusetyenziswa. ...Funda ngokugqithisileyo -

Yeyiphi i-milling cutter esetyenziselwa ukucubungula i-aluminium alloy?

Ekubeni ukusetyenziswa ngokubanzi kwe-aluminium alloy kuphezulu kakhulu, iimfuno zomatshini wokusika we-CNC ziphezulu kakhulu, kwaye iimfuno zezixhobo zokusika ziya kuphuculwa kakhulu ngokwemvelo. Ungayikhetha njani i-cutter yomatshini wokusika i-aluminium alloy? I-Tungsten steel milling cutter okanye i-white steel milling cutter inokukhetha...Funda ngokugqithisileyo -

IiMills ze-MSK Deep Groove End

Ii-end mills eziqhelekileyo zinobubanzi beblade kunye nobubanzi be-shank obufanayo, umzekelo, ububanzi beblade yi-10mm, ububanzi be-shank yi-10mm, ubude be-blade yi-20mm, kwaye ubude bubonke yi-80mm. I-deep groove milling cutter yahlukile. Ububanzi beblade ye-deep groove milling cutter...Funda ngokugqithisileyo -

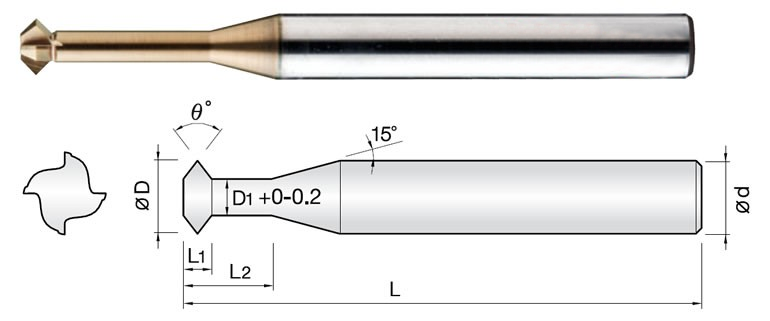

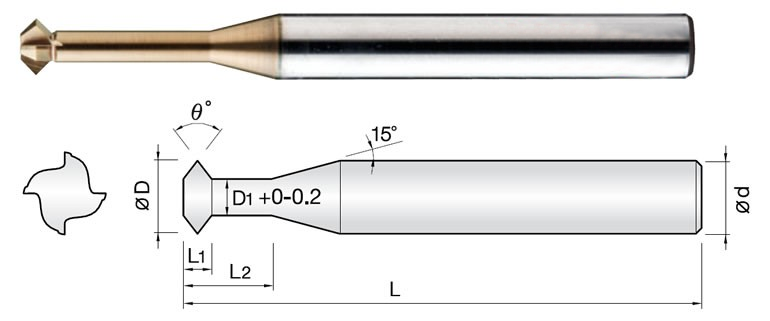

Izixhobo zeChamfer zeTungsten Carbide

(ekwaziwa ngokuba: zizixhobo zokutshiza i-alloy ngaphambili nangasemva, izixhobo zokutshiza i-tungsten steel chamfering ngaphambili nangasemva). I-engile yokusika ikona: iidigri ezingama-45 eziphambili, iidigri ezingama-60, iidigri ezi-5 zesibini, iidigri ezili-10, iidigri ezili-15, iidigri ezingama-20, iidigri ezingama-25 (zingenziwa ngokwezifiso ngokweemfuno zabathengi...Funda ngokugqithisileyo -

Isiphelo seMpumlo yeBhola yePCD

I-PCD, ekwaziwa ngokuba yidayimani ye-polycrystalline, luhlobo olutsha lwezinto eziqinileyo ezenziwe yidayimani enyibilikisa i-cobalt njenge-binder kubushushu obuphezulu be-1400°C kunye noxinzelelo oluphezulu lwe-6GPa. Iphepha le-PCD elidityanisiweyo liyimpahla edityanisiweyo eqinileyo eyenziwe yi-PCD layer combi eyi-0.5-0.7mm ubukhulu...Funda ngokugqithisileyo -

Umsiki wokugaya umbona weCarbide

Umsiki wokusila umbona,Umphezulu ubonakala ngathi yi-dense spiral reticulation, kwaye imingxunya ayinzulu kangako. Ngokuqhelekileyo isetyenziselwa ukucubungula ezinye izinto ezisebenzayo. Umsiki wokusila we-carbide eqinileyo une-cutting edge eyenziwe ziiyunithi ezininzi zokusika, kwaye i-cutting edge...Funda ngokugqithisileyo -

Isigayo Sokugqibela Esikhazimlayo Esiphezulu

Yamkela i-German K44 hard alloy bar kunye nezinto zentsimbi ze-tungsten tungsten ze-German, ezinobunzima obuphezulu, ukumelana okuphezulu kunye nokukhazimla okuphezulu. Isebenza kakuhle ekugayeni nasekusikeni, nto leyo ephucula kakhulu ukusebenza kakuhle kunye nokugqitywa komphezulu. I-aluminium milling cutter ene-gloss ephezulu ifanelekile...Funda ngokugqithisileyo -

Indlela yokukhetha umbhobho womatshini

1. Khetha ngokwendawo yokunyamezelana kwempompo. Iimpompo zomatshini zasekhaya ziphawulwe ngekhowudi yendawo yokunyamezelana yobubanzi bepitch: H1, H2, kunye ne-H3 ngokwahlukeneyo zibonisa iindawo ezahlukeneyo zendawo yokunyamezelana, kodwa ixabiso lokunyamezelana liyafana. Ikhowudi yendawo yokunyamezelana yesandla...Funda ngokugqithisileyo -

I-T-slot End Mill

Ukuze i-Chamfer Groove Milling Cutter isebenze kakuhle kwaye ikwazi ukutyiwa kakhulu, ikwazi nokusika ubunzulu obuphezulu. Ikwafanelekile nakwi-groove bottom machining kwizicelo ze-circular milling. I-Tangentially efakwe kwi-indexable ifaka isiqinisekiso sokususwa kwee-chip ezifanelekileyo kunye nokusebenza okuphezulu ngamaxesha onke. I-T-slot milling cu...Funda ngokugqithisileyo