Sesebelisoa sa ho seha li-cutter tsa Tungsten Carbide Dovetail

Ntho eohle e entsoe ka tšepe ea tungsten ea boleng bo holimo, e nang le bothata bo phahameng le ho hanyetsa ho tsofala ho hoholo. Tšebeliso ea thepa ea tšepe ea alloy e sebetsang hantle, e nang le khanyetso e ntle ea tšisinyeho ea lefatše. E entsoe ka mekoallo e mecha ea tšepe ea tungsten e nang le lithollo tse ntle, e nang le khanyetso le matla a ho tsofala a hoholo. Ke thipa ea dovetail ea boleng bo holimo bakeng sa lits'ebetso tsa ho seha ka lebelo le phahameng le thata. E ka etsa ts'ebetso e potlakileng holim'a tšepe e sa ruseng, motsoako oa aluminium, tšepe e lahliloeng le lisebelisoa tse ling tse ka tlase ho HRC55 (ho kenyeletsoa HRC55). Ho sebetsa ka mechini, ho fokotsa palo ea liphetoho tsa lisebelisoa le ho ntlafatsa bokhoni.

Molemo:

E theko e tlase 'me re khetha tšepe ea tungsten ea boleng bo holimo e nang le bothata bo phahameng le ho hanyetsa ho tsofala ho phahameng

Ho haha mochini ka nepo, ho sila hantle. Ho sebetsana ka nepo, ho fokotsa li-burrs ts'ebetsong ea sehlahisoa - boreledi bo phahameng

Taolo e tiileng ea boleng, ho nepahala ho phahameng le lihlahisoa tse bohale tse felileng

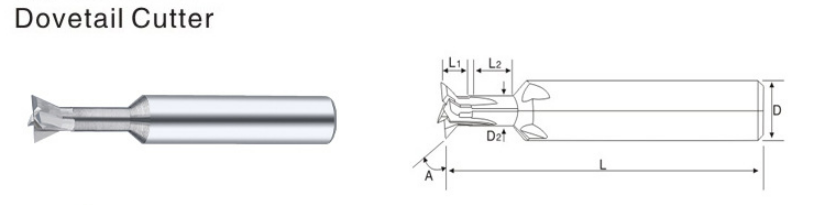

Tšobotsi:

1. Likhutlo tse bohale tse ntlafatsang haholo bokgoni ba ho seha

2. Moralo o otlolohileng oa groove, ho tlosa chip e boreleli ntle le ho khomarela thipa

3. Qoba moea ka tsela e utloahalang 'me u lelefatse bophelo ba sesebelisoa

4. Matlafatsa ho tiea ha bohale ba ho seha, 'me lebanta la bohale ba arc le tsamaisa lehlakore le bohale haholoanyane 'me le tlosa bohlasoa ka katleho.

5. Moqomo o moholo oa ho tlosa li-chip o fokotsa matla, 'me ho seha ho bonolo haholoanyane, ho fihlela ts'ebetso e phahameng ea ho sebetsa, 'me mosebetsi o nepahetse haholoanyane ebile o makatsa haholoanyane.

| Mofuta | Sehahi sa ho Sila sa Tungsten Dovetail | Thepa | Tšepe ea Tungsten |

| Lisebelisoa tsa Mosebetsi | Tšepe e sa ruseng, aluminium, tšepe e qhibilihisitsoeng, tšepe e lahliloeng, motsoako oa aluminium, tšepe e kopantsoeng, motsoako oa titanium, jj. | Sesebelisoa sa mochini se sebetsang | Setsi sa ho sebetsa ka mechine sa CNC, Sesebelisoa sa mochini sa CNC, mochini o betlang, mochini o betlang, mochini o lebelo le phahameng |

| Sephutheloana sa Lipalangoang | Lebokose | Flute | 3/4 |

| Ho koahela | No | Bothata | <=55 |

| Bophara ba Flute (mm) | D2(mm) | L2(mm) | Bophahamo ba Flute (mm) | Bophara ba Shank(mm) | Bolelele bohle (mm) | Liphala |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 | 20 | 75 | 4 |

Sebelisa:

E sebelisoa haholo masimong a mangata

Tlhahiso ea Lifofane

Tlhahiso ea Mechini

Moetsi oa likoloi

Ho etsa hlobo

Tlhahiso ea Motlakase

Ho sebetsana le lathe