HRC55 Metric Carbide Mohato Mohato Bakeng sa Metal

Likaroloana:

Ho cheka le ho qhekella

Ho tlosoa ha li-chips tse bonolo

Tšepe ea tungsten e khethiloeng

E loketse ho phunya lesoba la mohato ka nako e le 'ngoe

Molemo:

1. Likoluoa tse kholo tsa chip li ka netefatsa ho tlosoa ha li-chip tse boreleli le ho ntlafatsa katleho ea machining

2. AlTiN/TiSiN/AlTiSiN/TiN/ntle le ho roala, kaofela li teng

3. Carbide e entsoeng ka samente

E sebelisa thepa ea motheo ea tšepe ea tungsten e entsoeng hantle, e na le boima bo phahameng le matla a betere a ho kobeha, sesebelisoa ha se sebetse haholoanyane, ha se bonolo ho phunya le ho robeha, 'me se na le nako e telele ea tšebeletso.

4. Ho bonolo ho sebetsa chamfering

Sebopeho sa chamfered shank se bonolo ho se tiisa.

Malebela a ho Hlokomela Mohato oa ho Drill Bit

Haeba u ka khona ho hlokomela sesebelisoa sa hau hantle, se tla sebeletsa morero ka nako e telele. Ka tsela ena, u ke ke ua tlameha ho sebelisa chelete e eketsehileng ho reka lisebelisoa tse ncha haufinyane. Joale, na ho thata haholo ho hlokomela lisebelisoa tsa ho cheka mehato? Ho hang, ho bonolo kamoo ho ka khonehang. Jwale, a re ithuteng ho e etsa ka nepo.

Mohato oa 1: U hloka ho hloekisa likotoana nako le nako nakong ea mosebetsi. Ho seng joalo, e tla ba le tšekamelo ea ho senya kapele ho feta kamoo ho neng ho lebelletsoe.

Mohato oa 2: U tlameha ho hlakola karolo eo hang ha u qetile ka mosebetsi.

Mohato oa 3: Hlakola litšila life kapa life ka ho sebelisa borashe ba meno.

Mohato oa 4: U ka sebelisa oli ea mochini ka mor'a moo ho likotoana.

| Mofuta oa letsoho | Setshoaro se otlolohileng | Lisebelisoa tsa Workpiece | Lisebelisoa tsa tšepe tse kang tšepe, koporo, aluminium, tšepe ea alloy, tšepe e entsoeng ka tšepe, joalo-joalo. |

| Brand | MSK | Lintho tse bonahalang | Carbide |

| Mosebetsi | Cheka likoti tse otlolohileng, li-chamfers tsa counterbore | Bophara ba Hlooho e Nyenyane(mm) | 3.4-14.0 |

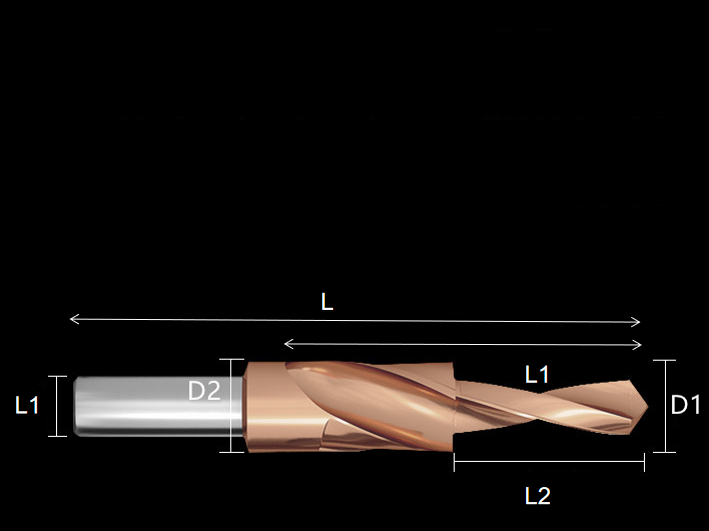

| D1(mm) | D2(mm) | L(mm) | L1(mm) | L2(mm) |

| 3.4 | 6.5 | 65 | 35 | 13 |

| 4.5 | 8.0 | 75 | 42 | 18 |

| 5.5 | 9.5 | 85 | 50 | 22 |

| 6.6 | 11.0 | 90 | 53 | 25 |

| 9.0 | 14.0 | 95 | 53 | 28 |

| 11.0 | 17.5 | 105 | 63 | 30 |

| 14.0 | 20.0 | 110 | 68 | 32 |