A manufacturing breakthrough centered on innovative flow drill bits (also known as thermal friction drill bits or flowdrill) is transforming how industries create strong, reliable threads in thin sheet metal and tubing. This friction-based technology eliminates the need for traditional drilling and tapping, offering significant gains in strength, speed, and cost-efficiency, particularly in automotive, aerospace, and electronics sectors.

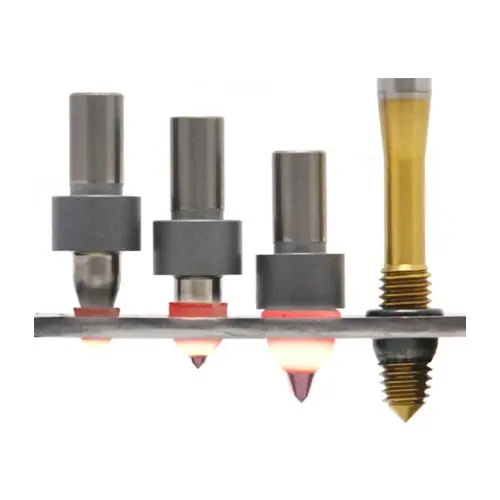

The core innovation lies in the unique process enabled by these specialized bits. Unlike conventional drills that cut and remove material, a flow drill bit generates intense heat through a combination of extremely high rotational speed and controlled axial pressure. As the specially shaped tungsten carbide tip contacts the workpiece surface, friction rapidly heats the underlying metal – typically steel, stainless steel, aluminum, or copper alloys – to its plastic state (around 600-900°C depending on the material).

This formed bushing is a critical feature. It typically extends up to 3 times the original thickness of the base material. For example, threading a 2mm thick sheet results in a robust 6mm tall collar. This significantly increases the thread engagement depth far beyond what would be possible with the raw material thickness alone.

Following the formation of the bushing, the process often continues seamlessly. A standard tap follows the flow drill bit, either immediately in the same machine cycle (on compatible equipment) or in a subsequent operation. The tap cuts precise threads directly into the newly formed, thick-walled bushing. Since the bushing is part of the original material grain structure, not an added insert, the resulting threads boast exceptional high precision and high strength.

Key Advantages Driving Adoption:

Unmatched Strength in Thin Materials: The 3x bushing provides vastly superior thread engagement compared to tapping the base thickness directly or using inserts.

Speed & Efficiency: Combines hole making and bushing formation into one ultra-fast operation (often seconds per hole), eliminating separate drilling, deburring, and insert installation steps.

Material Savings: No chips are generated during the flow drilling phase, reducing material waste.

Sealed Joints: The displaced material flows tightly around the hole, often creating a leak-proof joint ideal for fluid or pressure applications.

Reduced Tooling: Eliminates the need for nuts, weld nuts, or riveted inserts, simplifying BOMs and logistics.

Cleaner Process: Minimal chips and no need for cutting fluids in many applications (lubrication is sometimes used for bit life or specific materials).

Applications Abound: The technology is rapidly gaining traction wherever lightweight thin materials need robust threaded connections:

Automotive: Electric vehicle battery trays, chassis components, brackets, exhaust systems, seat frames.

Aerospace: Interior panels, ducting, lightweight structural brackets.

Electronics: Server racks, enclosure panels, heat sinks.

HVAC: Sheet metal ducting connections, brackets.

Furniture & Appliances: Structural frames requiring hidden, strong fastening points.

Manufacturers of flow drill bits continue to refine geometries, coatings, and material compositions to extend tool life, improve performance on advanced alloys, and optimize the process for automation. As industries relentlessly pursue lightweighting and manufacturing efficiency, thermal friction drilling, powered by the innovative flowdrill bit, is proving to be an indispensable solution for creating high-performance threads where they were once impossible or impractical. The era of struggling with weak threads in thin sheets is giving way to the strength and simplicity of friction-formed bushings.

Post time: Jul-30-2025