In industries where precision, speed, and material versatility are critical, Tungsten Carbide Rotary Burrs equipped with Single and Double Metal Grinding Heads are emerging as game-changers. Designed to meet the rigorous demands of modern fabrication, mold-making, and artisanal craftsmanship, these advanced rotary tools deliver unparalleled performance across metals and non-metals alike. Whether refining high-carbon steel or delicately shaping jade, the Carbide Rotary Burr Set combines durability with precision, making it an essential addition to workshops, factories, and creative studios worldwide.

Unrivaled Material Versatility

The defining strength of these Tungsten Carbide Rotary Burrs lies in their ability to process an extraordinary range of materials. From heavy-duty metals like iron, cast steel, bearing steel, high-carbon steel, alloy steel, and stainless steel to softer substrates such as copper, aluminum, marble, jade, and bone, these tools adapt seamlessly. This versatility eliminates the need for multiple specialized tools, streamlining workflows in industries like automotive manufacturing, aerospace engineering, jewelry design, and stone carving.

The Double Metal Grinding Head variant enhances this adaptability further. By integrating two distinct carbide grades or geometries into a single burr, users can tackle hybrid tasks—such as roughing and finishing—without switching tools. This dual functionality is particularly valuable in mold-making, where intricate cavities demand both aggressive material removal and ultra-fine detailing.

Superior Finish & High-Precision Capabilities

Engineered for excellence, these rotary burrs produce exceptionally smooth finishes with minimal effort. Their precision-ground tungsten carbide cutting edges ensure consistent contact with workpieces, reducing chatter and minimizing post-processing. This results in:

High surface quality: Achieve mirror-like finishes on metals or flawless detailing on brittle materials like marble and bone.

Complex geometries: Craft intricate mold cavities, undercuts, and contours with sub-millimeter accuracy.

Reduced secondary work: Eliminate the need for sanding or polishing in many applications, saving time and labor costs.

The Single Metal Grinding Head option excels in specialized tasks requiring uniform cutting action, such as deburring welded joints or refining engine components. Meanwhile, the double-head design offers unmatched flexibility for multi-stage projects.

Built for Speed, Engineered for Endurance

Optimized for use with power tools, pneumatic tools, or CNC machines, these rotary files operate efficiently at speeds ranging from 6,000 to 50,000 RPM. This broad range ensures compatibility with diverse equipment, from handheld die grinders to industrial machining centers. Key features include:

Thermal resistance: Tungsten carbide’s inherent heat tolerance prevents deformation even during prolonged high-speed use.

Extended lifespan: Outperforming HSS tools by up to 20x, these burrs resist wear, chipping, and corrosion.

Vibration reduction: Balanced grinding heads enhance stability, reducing operator fatigue and improving control.

Applications Across Industries

Mold & Die Manufacturing: Perfect for creating high-precision injection molds, stamping dies, or aerospace tooling.

Metal Fabrication: Deburr, chamfer, and shape components in automotive, shipbuilding, or structural steel projects.

Art & Sculpture: Carve intricate designs into stone, bone, or precious metals without compromising delicate materials.

Maintenance & Repair: Restore machinery parts, port engine heads, or repair alloy components with surgical precision.

Jewelry Crafting: Engrave fine patterns on gold, silver, or gemstone settings.

Technical Specifications

Material: Premium tungsten carbide with cobalt binder for enhanced toughness and wear resistance.

Shank Sizes: 3mm (compatible with most rotary tools and collets).

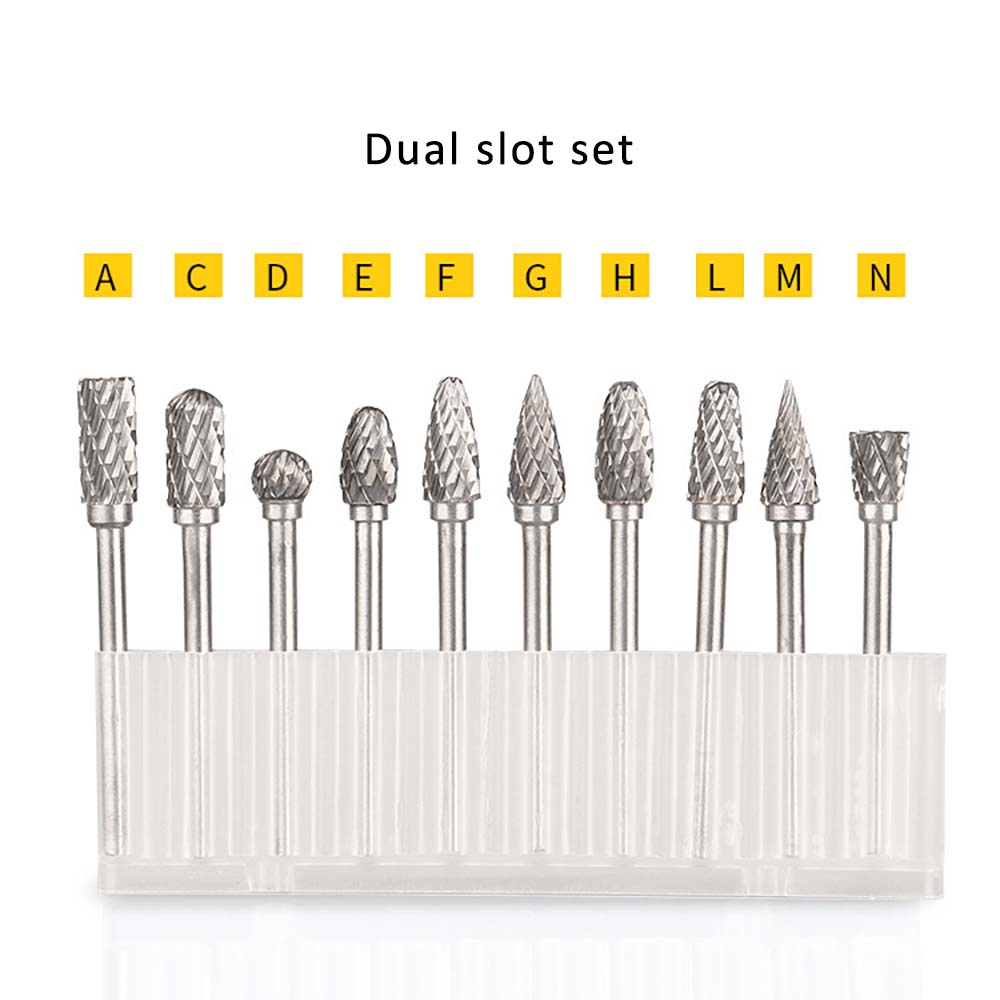

Grinding Head Types: Single-cut (for fine finishing) and double-cut (for aggressive stock removal).

Safety Compliance: Meets ISO 9001 and ANSI standards, with reinforced shanks to prevent breakage.

Why Choose This Carbide Rotary Burr Set?

Cost Efficiency: Reduce tool inventory costs with a single set that handles diverse materials and tasks.

Time Savings: Switch between roughing and finishing in seconds, thanks to the dual-head design.

Ergonomic Design: Lightweight, anti-slip coatings, and optimized balance improve user comfort during extended use.

Upgrade Your Workshop Today

Discover how our Single and Double Metal Grinding Head Tungsten Carbide Rotary Burrs can elevate your productivity and precision. Visit https://www.mskcnctools.com/ to explore technical datasheets, request samples, or connect with our expert team for tailored recommendations.

Post time: May-12-2025