In the relentless pursuit of stronger, lighter, and more efficient manufacturing, a transformative technology is gaining significant traction: Thermal Friction Drilling (TFD). This innovative process, powered by specialized Thermal Friction Drill Bit Sets, is redefining how industries create high-integrity threaded connections in thin sheet metal, eliminating the need for traditional nuts, weld nuts, or cumbersome rivets.

The Core Innovation: Heat, Friction, and Precision

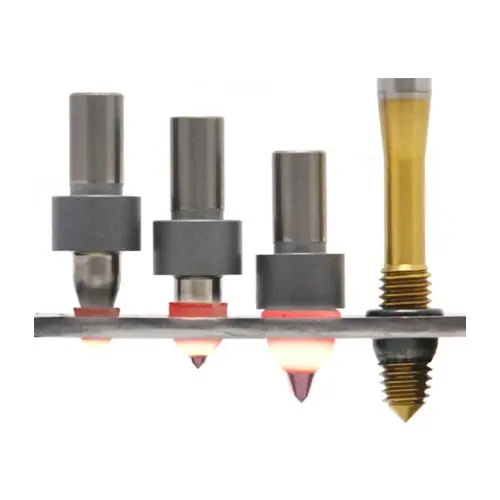

At the heart of TFD lies the ingenious principle of generating localized heat purely through mechanical action. A high-performance Flow Drill, typically featuring a wear-resistant carbide tip, rotates at extremely high speeds (often 2000-5000 RPM) while significant axial pressure is applied. The friction generated between the rotating Carbide Flow Drill Bit and the workpiece material (steel, aluminum, stainless steel, etc.) rapidly heats the metal at the precise contact point to near or past its plasticization temperature – typically between 500°C to 1000°C depending on the material.

Beyond Drilling: Creating Integrated Strength

This is where TFD transcends conventional drilling. As the plasticized material yields, the unique geometry of the Flow Drill doesn't just cut; it displaces the molten metal radially outward and axially downward. This controlled flow forms a seamless, boss-like bushing directly from the parent material itself. Crucially, this bushing is approximately 3 times the thickness of the original sheet metal. This dramatic increase in material thickness around the hole is the key to TFD's strength advantage.

The Final Step: Precision Threading

Once the bushing is formed and begins to cool, the Flow Drill retracts. The process often seamlessly transitions to tapping. A standard tap (or sometimes integrated into the tool sequence) is driven through the newly formed, still-warm bushing. Tapping into this significantly thicker section, rather than the thin base material, results in threads boasting high-precision tolerances and exceptional strength. The grain structure of the displaced and reformed material often contributes to enhanced fatigue resistance compared to cut threads.

Why Industry is Embracing Flow Drills:

Unparalleled Strength: Threads engage material 2-3x thicker than the base sheet, offering pull-out and strip strengths far exceeding traditional tapped holes or many clinch nuts.

Material Savings: Eliminates the need for added fasteners like nuts, weld nuts, or rivet nuts, reducing part count, weight, and inventory.

Process Efficiency: Combines drilling, bushing formation, and tapping into a single, rapid operation on standard CNC machines or dedicated cells. No pre-punching or secondary operations needed.

Sealed Joints: The plastic flow often creates a smooth, sealed hole surface, improving corrosion resistance and preventing fluid leaks.

Versatility: Highly effective on a wide range of ductile metals, from mild steel and aluminum to stainless steel and some alloys.

Reduced Heat Affected Zone (HAZ): Despite the heat generation, the process is highly localized, minimizing distortion or metallurgical changes to the surrounding material compared to welding.

Applications Driving Demand:

The unique benefits of Thermal Friction Drill Bit Sets are finding critical applications across demanding sectors:

- Automotive: Chassis components, seat frames, brackets, battery enclosures (EVs), exhaust systems – anywhere strong, reliable threads in thin gauge metal are essential.

- Aerospace: Lightweight structures, interior components, avionics mounts – benefiting from weight savings and high-strength fastening.

- HVAC & Appliance: Sheet metal enclosures, ducting, compressor mounts – requiring robust, leak-resistant joints.

- Electronics Enclosures: Server racks, control cabinets – needing strong mounting points without added hardware bulk.

- Renewable Energy: Solar panel frames, wind turbine components – demanding durability in thin materials exposed to harsh environments.

The Carbide Advantage:

The extreme conditions at the drill tip – intense friction, high temperatures, and significant pressure – necessitate tools of exceptional hardness and thermal stability. Carbide Flow Drill Bits, often featuring specialized coatings (like TiAlN), are the industry standard. Their wear resistance ensures consistent hole quality, bushing formation, and long tool life, making the Thermal Friction Drill Bit Set a cost-effective solution despite the initial tooling investment.

Conclusion:

Thermal Friction Drilling, enabled by advanced Carbide Flow Drill Bits and optimized Flow Drill processes, is more than just a hole-making technique. It's a material transformation process that engineers strength directly into thin-gauge components. By creating thick, integral bushings for high-strength threads in a single, efficient operation, TFD solves persistent fastening challenges, drives down costs, and enables lighter, stronger designs. As manufacturing demands for efficiency and performance intensify, the adoption of this innovative Flow Drill technology is poised for continued significant growth, solidifying its place as a cornerstone of modern precision metalworking.

Post time: Aug-07-2025