Part 1

When it comes to precision machining, having the right tools is essential for achieving accurate and high-quality results. One such tool that is indispensable in the machining industry is the carbide spot drill. Known for its durability, precision, and versatility, the carbide spot drill is a must-have for any machinist or manufacturing professional. In this article, we will explore the features and benefits of the MSK brand carbide spot drill, and why it is the ultimate tool for precision machining.

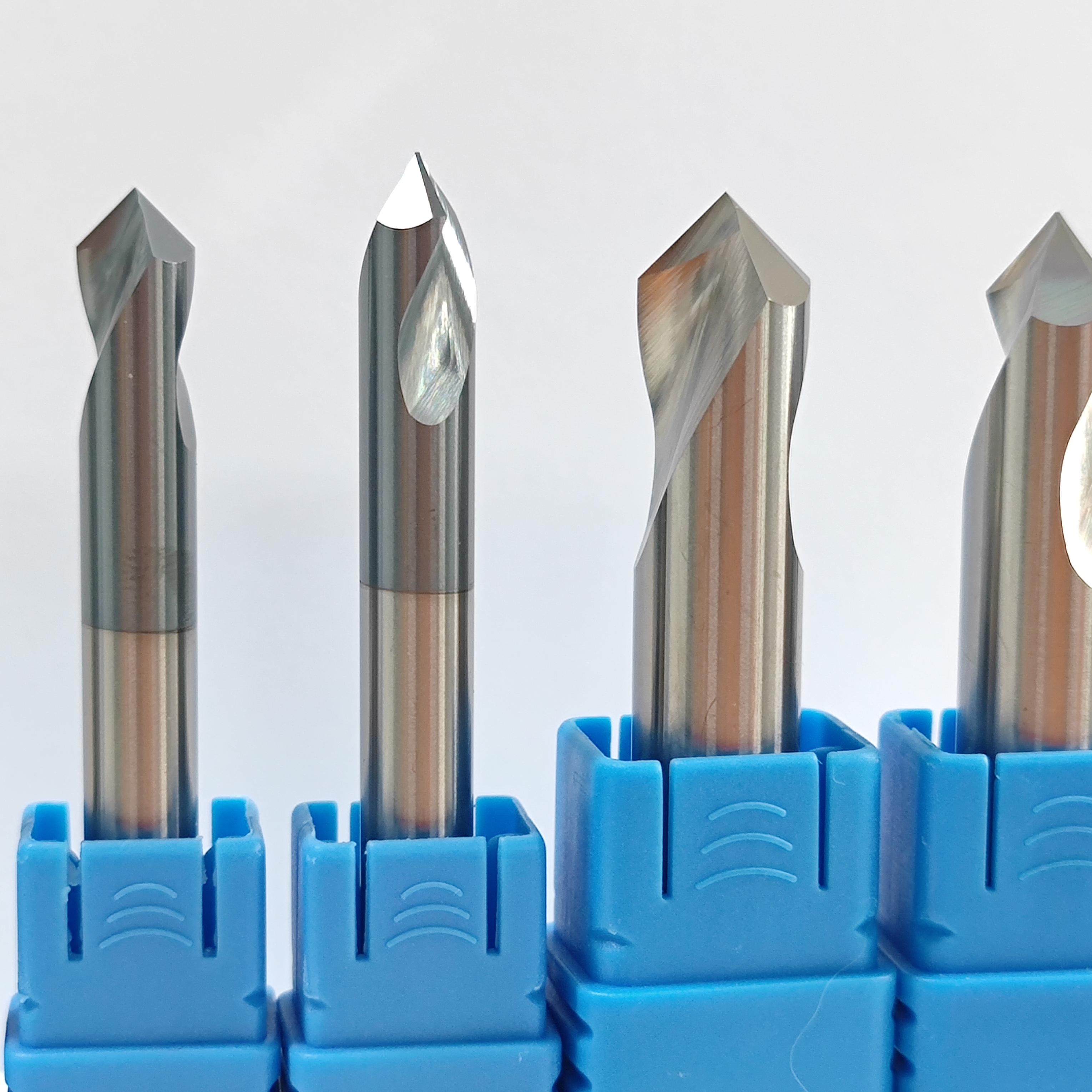

The MSK brand carbide spot drill is designed to meet the demands of modern machining applications. Made from high-quality carbide material, this spot drill offers exceptional hardness and wear resistance, making it suitable for a wide range of materials, including steel, aluminum, and other alloys. The use of carbide also ensures that the drill maintains its sharpness and cutting edge for extended periods, resulting in consistent and precise machining operations.

One of the key features of the MSK brand carbide spot drill is its specialized geometry, which is optimized for spot drilling applications. The drill features a pointed tip with a specific angle, allowing it to create precise and accurate spot holes with minimal chipping or burring. This is particularly important in machining operations where the creation of clean and smooth spot holes is crucial for subsequent drilling or tapping processes.

Part 2

In addition to its superior cutting performance, the MSK brand carbide spot drill is also designed for efficient chip evacuation. The flute design and chip-breaking capabilities of the drill ensure that chips are effectively removed from the cutting area, preventing chip buildup and minimizing the risk of tool damage or workpiece defects. This feature is especially beneficial when working with materials that are prone to chip formation, such as stainless steel or high-temperature alloys.

Furthermore, the MSK brand carbide spot drill is available in a range of sizes and diameters, allowing machinists to select the most suitable tool for their specific application requirements. Whether it's for creating small, precise spot holes or larger diameter bores, the versatility of the carbide spot drill makes it a valuable asset in any machining environment. Additionally, the availability of various shank styles, such as straight shank or Morse taper, further enhances the compatibility of the drill with different machine setups and toolholding systems.

Part 3

Another notable advantage of the MSK brand carbide spot drill is its long tool life and durability. The combination of high-quality carbide material and advanced coating technologies results in a drill that can withstand the demands of high-speed machining and heavy-duty applications. This longevity not only reduces tool replacement costs but also contributes to overall productivity and efficiency in the machining process.

When it comes to precision machining, accuracy and repeatability are paramount. The MSK brand carbide spot drill excels in delivering consistent and precise results, thanks to its rigid construction and stable cutting performance. Machinists can rely on this tool to achieve tight tolerances and surface finishes, ensuring that their machined components meet the required specifications and quality standards.

In conclusion, the MSK brand carbide spot drill is a top-tier tool that offers exceptional performance and reliability for precision machining applications. Its superior cutting capabilities, efficient chip evacuation, versatility, and durability make it an indispensable asset for machinists and manufacturing professionals. Whether it's for creating spot holes, chamfering, or countersinking, the carbide spot drill delivers the precision and consistency needed to elevate machining operations to the next level. With the MSK brand carbide spot drill in their arsenal, machinists can confidently tackle a wide range of machining tasks with precision and efficiency.

Post time: Apr-26-2024