The relentless drive towards lighter, stronger, and more efficient vehicles, particularly with the explosive growth of Electric Vehicles (EVs), places immense pressure on automotive manufacturing. Traditional methods of creating strong threaded connections in thin sheet metal – a staple of modern car bodies, frames, and enclosures – often involve added fasteners like weld nuts or rivet nuts. These introduce complexity, weight, potential failure points, and slower cycle times. Enter Thermal Friction Drilling (TFD) and its specialized tools – Carbide Flow Drill Bits and Thermal Friction Drill Bit Sets – a technology rapidly transforming automotive production lines by automating the creation of integral, high-strength threads directly within thin materials.

The Automotive Fastening Challenge: Weight, Strength, Speed

Automotive engineers constantly battle the weight-strength paradox. Thin, high-strength steels and aluminum alloys are essential for reducing vehicle mass and improving fuel efficiency or EV range. However, creating reliable load-bearing threads in these thin sections is problematic:

Limited Engagement: Traditional tapping into thin sheet offers minimal thread engagement, leading to low pull-out strength and susceptibility to stripping.

Added Complexity & Weight: Weld nuts, clinch nuts, or rivet nuts add parts, require secondary operations (welding, pressing), increase weight, and introduce potential corrosion sites or quality control issues.

Process Bottlenecks: Separate drilling, fastener insertion/attachment, and tapping steps slow down high-volume production lines.

Heat & Distortion: Welding nuts generates significant heat, potentially warping thin panels or affecting material properties in the Heat Affected Zone (HAZ).

Flow Drills: The Automated Solution on the Line

Thermal Friction Drilling, integrated into CNC machining centers, robotic cells, or dedicated multi-spindle machines, provides a compelling answer:

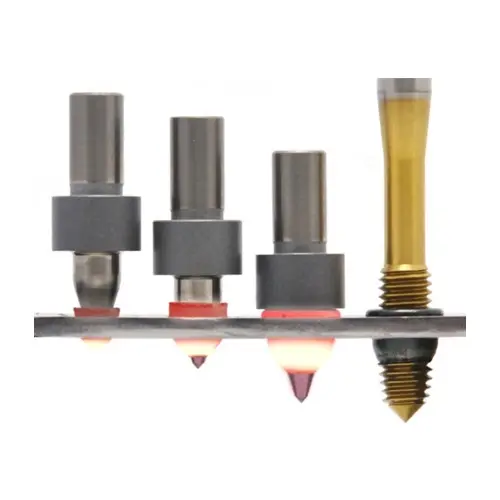

Single Operation Powerhouse: The core magic of TFD lies in combining drilling, bushing formation, and tapping into one seamless, automated operation. A single Carbide Flow Drill Bit, rotating at high speed (typically 3000-6000 RPM for steel, higher for aluminum) under significant axial force, generates intense friction heat. This plasticizes the metal, allowing the bit's unique geometry to flow and displace the material, forming a seamless, integral bushing approximately 3 times the thickness of the original sheet.

Immediate Tapping: As the Flow Drill retracts, a standard tap (often on the same tool holder in an auto-exchange system or a synchronized second spindle) immediately follows, cutting high-precision threads into this newly formed, thick-walled bushing. This eliminates handling between operations and drastically reduces cycle time.

Robotic Integration: Thermal Friction Drill Bit Sets are ideally suited for robotic arms. Their ability to perform the entire thread creation process with a single tool path (drill down, form bushing, retract, tap down, retract) simplifies robot programming and execution. Robots can precisely position the tool over complex contours on body-in-white (BIW) structures or sub-assemblies.

Why Automotive Manufacturers are Adopting Flow Drills:

Radically Increased Thread Strength: This is the paramount advantage. Threads engage the thick bushing (e.g., forming a 9mm tall bushing from 3mm sheet), resulting in pull-out and strip strengths often exceeding those of weld nuts or rivet nuts. This is critical for safety-critical components (seat belt anchors, suspension mounts) and high-vibration areas.

Significant Weight Reduction: Eliminating the weld nut, rivet nut, or clinch nut itself removes weight. More importantly, it often allows designers to use thinner gauge material overall since the formed bushing provides localized reinforcement where strength is needed, without adding weight elsewhere. Grams saved per connection multiply rapidly across a vehicle.

Unmatched Process Efficiency & Speed: Combining three operations into one slashes cycle times. A typical thermal friction drilling and tapping cycle can be completed in 2-6 seconds, significantly faster than sequential drilling, nut placement/welding, and tapping. This boosts throughput on high-volume lines.

Enhanced Quality & Consistency: Automated TFD delivers exceptional hole-to-hole consistency. The process is highly repeatable under controlled CNC or robotic parameters, minimizing human error common in manual nut placement or welding. The formed bushing creates a smooth, often sealed hole surface, improving corrosion resistance and paint adhesion.

Reduced System Complexity & Cost: Eliminating separate nut feeders, welding stations, weld controllers, and associated quality checks reduces capital equipment cost, floor space requirements, maintenance complexity, and consumables (no welding wire/gas, no nuts).

Improved Joint Integrity: The integral bushing forms a metallurgically continuous part of the base material. There's no risk of the nut loosening, spinning, or falling out like mechanical fasteners, and no HAZ concerns comparable to welding.

Material Versatility: Carbide Flow Drill Bits effectively handle the diverse materials in modern autos: mild steel, High-Strength Low-Alloy (HSLA) steel, Advanced High-Strength Steel (AHSS), aluminum alloys (5xxx, 6xxx), and even some stainless components. Tool coatings (like AlCrN for aluminum, TiAlN for steel) optimize performance and life.

Key Automotive Applications Driving Adoption:

EV Battery Enclosures & Trays: Perhaps the single biggest driver. These large, thin-walled structures (often aluminum) require numerous high-strength, leak-proof threaded points for mounting, covers, cooling plates, and electrical components. TFD provides the required strength without adding weight or complexity. The sealed bushing helps prevent coolant ingress.

Chassis & Subframes: Brackets, crossmembers, and suspension mounting points benefit from TFD's strength and vibration resistance in thin, high-strength steels.

Seat Frames & Mechanisms: Critical safety components demanding extremely high pull-out strength for belt anchors and robust mounting points. TFD eliminates bulky fasteners and welding distortion.

Body-in-White (BIW): Various brackets, reinforcements, and interior mounting points within the vehicle structure where added nuts are cumbersome and welding is undesirable.

Exhaust Systems: Mounting hangers and heat shield attachments on thin stainless steel or aluminized steel benefit from the corrosion-resistant sealed hole and vibration resistance.

HVAC Units & Ducting: Mounting points and service access panels requiring robust threads in thin sheet metal enclosures.

The Carbide Imperative in Automotive TFD:

Automotive production runs are long, demanding absolute tool reliability and longevity. Carbide Flow Drill Bits are non-negotiable. They withstand the extreme friction temperatures (often exceeding 800°C/1472°F at the tip), high rotational speeds, and significant axial forces encountered thousands of times per shift. Advanced micro-grain carbide substrates and specialized coatings (TiAlN, AlTiN, AlCrN) are tailored for specific automotive materials, maximizing tool life and maintaining consistent bushing formation and hole quality critical for automated processes. A well-maintained Thermal Friction Drill Bit Set can process thousands of holes before requiring replacement, offering excellent cost-per-hole economics.

Integration & The Future:

Successful integration involves precise control of RPM, feed rates, axial force, and cooling (often minimal air blast rather than flood coolant to avoid quenching the forming bushing). Monitoring systems track tool wear and process parameters for predictive maintenance. As automotive design pushes further towards multi-material structures (e.g., aluminum bodies on steel frames) and even greater lightweighting, the demand for Flow Drill technology will only intensify. Its ability to create localized, ultra-strong threads in thin, diverse materials, directly within automated production flows, positions Thermal Friction Drilling not just as an alternative, but as the future standard for efficient, high-strength automotive fastening. It’s a revolution quietly forging stronger, lighter vehicles one integral bushing at a time.

Post time: Aug-21-2025