Tshooj 1

Thaum nws los txog rau kev ua haujlwm kom raug, muaj cov cuab yeej zoo yog qhov tseem ceeb rau kev ua tiav qhov tseeb thiab zoo. Ib qho cuab yeej uas tsis tuaj yeem tsis tau hauv kev lag luam machining yog lub carbide spot drill. Paub txog nws qhov ruaj khov, qhov tseeb, thiab kev hloov pauv tau yooj yim, lub carbide spot drill yog qhov yuav tsum muaj rau txhua tus kws kho tshuab lossis cov kws tshaj lij tsim khoom. Hauv tsab xov xwm no, peb yuav tshawb nrhiav cov yam ntxwv thiab cov txiaj ntsig ntawm MSK hom carbide spot drill, thiab vim li cas nws yog lub cuab yeej zoo tshaj plaws rau kev ua haujlwm kom raug.

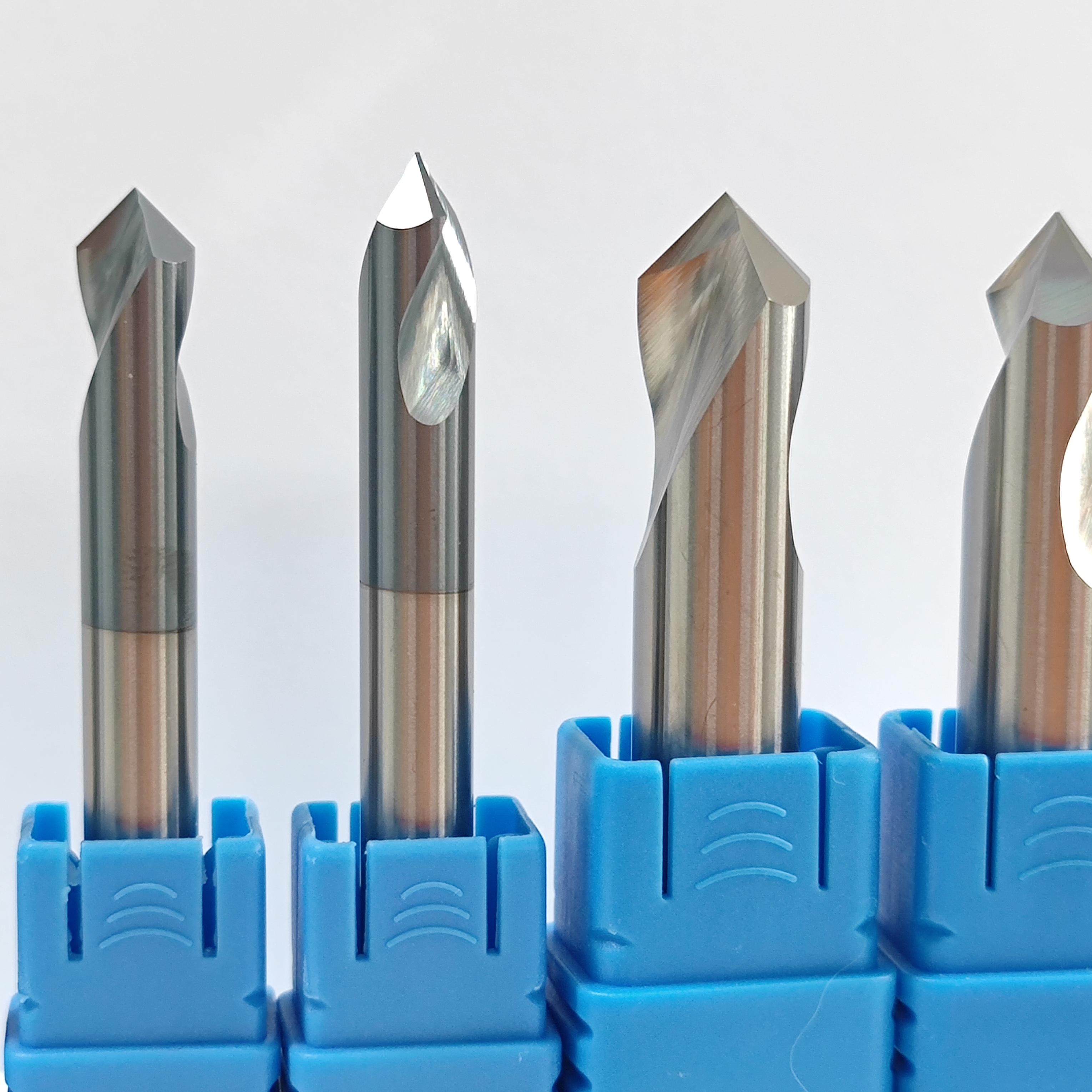

Lub tshuab laum carbide hom MSKyog tsim los ua kom tau raws li qhov xav tau ntawm cov ntawv thov machining niaj hnub. Ua los ntawm cov khoom siv carbide zoo, lub tshuab laum no muaj qhov nyuaj thiab tiv taus kev hnav, ua rau nws haum rau ntau yam khoom siv, suav nrog hlau, txhuas, thiab lwm yam alloys. Kev siv carbide kuj ua kom ntseeg tau tias lub tshuab laum tswj nws qhov ntse thiab txiav ntug rau lub sijhawm ntev, ua rau muaj kev ua haujlwm machining sib xws thiab meej.

Ib qho ntawm cov yam ntxwv tseem ceeb ntawmMSK hom carbide qhov chaw laumyog nws cov qauv tshwj xeeb, uas tau tsim kho kom zoo rau kev siv qhov chaw drilling. Lub laum muaj lub taub hau ntse nrog lub kaum sab xis tshwj xeeb, ua rau nws tsim cov qhov chaw meej thiab raug nrog tsawg kawg chipping lossis burring. Qhov no yog qhov tseem ceeb tshwj xeeb hauv kev ua haujlwm machining qhov twg kev tsim cov qhov chaw huv thiab du yog qhov tseem ceeb rau kev drilling lossis tapping tom qab.

Tshooj 2

Ntxiv rau nws qhov kev ua tau zoo tshaj plaws ntawm kev txiav, qhovMSK hom carbide qhov chaw laumkuj tsim los rau kev tshem tawm cov chips kom zoo. Lub raj tsim thiab lub peev xwm rhuav cov chips ntawm lub laum ua kom ntseeg tau tias cov chips raug tshem tawm ntawm thaj chaw txiav, tiv thaiv kev sib sau ua ke ntawm cov chips thiab txo qhov kev pheej hmoo ntawm kev puas tsuaj rau cov cuab yeej lossis cov khoom ua haujlwm tsis zoo. Qhov tshwj xeeb no yog qhov tshwj xeeb tshaj yog thaum ua haujlwm nrog cov ntaub ntawv uas yooj yim tsim cov chips, xws li hlau tsis xeb lossis cov hlau kub siab.

Tsis tas li ntawd xwb, lub tshuab laum carbide MSK hom muaj ntau qhov loj thiab txoj kab uas hla, uas cia cov kws kho tshuab xaiv cov cuab yeej tsim nyog tshaj plaws rau lawv cov kev xav tau tshwj xeeb. Txawm hais tias nws yog rau kev tsim cov qhov me me, meej lossis cov qhov loj dua, qhov ua tau ntau yam ntawm lub tshuab laum carbide ua rau nws yog ib qho khoom muaj nqis hauv txhua qhov chaw ua haujlwm. Tsis tas li ntawd xwb, qhov muaj ntau hom shank, xws li shank ncaj lossis Morse taper, ua rau lub tshuab laum sib xws nrog ntau lub tshuab teeb tsa thiab cov cuab yeej tuav.

Tshooj 3

Lwm qhov zoo dua ntawm qhov kev ua siMSK hom carbide qhov chaw laumyog nws lub cuab yeej siv tau ntev thiab ruaj khov. Kev sib xyaw ua ke ntawm cov khoom siv carbide zoo thiab cov thev naus laus zis siab heev ua rau lub laum uas tuaj yeem tiv taus qhov xav tau ntawm kev siv tshuab ceev ceev thiab kev siv hnyav. Lub sijhawm ntev no tsis yog tsuas yog txo cov nqi hloov cuab yeej xwb tab sis kuj pab txhawb rau kev tsim khoom thiab kev ua haujlwm zoo hauv cov txheej txheem machining.

Thaum nws los txog rau kev ua haujlwm kom raug, qhov tseeb thiab rov ua dua yog qhov tseem ceeb. Lub tshuab laum carbide hom MSK zoo tshaj plaws hauv kev xa cov txiaj ntsig zoo sib xws thiab meej, ua tsaug rau nws txoj kev tsim kho ruaj khov thiab kev ua haujlwm txiav ruaj khov. Cov kws kho tshuab tuaj yeem cia siab rau cov cuab yeej no kom ua tiav qhov kev kam rau siab thiab qhov tiav ntawm qhov chaw, kom ntseeg tau tias lawv cov khoom siv tshuab ua tau raws li cov lus qhia thiab cov qauv zoo.

Xaus lus, lub tshuab laum carbide hom MSK yog lub cuab yeej zoo tshaj plaws uas muaj kev ua tau zoo thiab kev ntseeg siab rau kev siv tshuab precision. Nws muaj peev xwm txiav tau zoo, tshem tawm cov chips zoo, ua tau ntau yam, thiab ruaj khov ua rau nws yog ib qho khoom muaj nqis rau cov kws kho tshuab thiab cov kws tshaj lij tsim khoom. Txawm hais tias nws yog rau kev tsim cov qhov, chamfering, lossis countersinking, lub tshuab laum carbide muab qhov tseeb thiab kev sib xws uas xav tau los txhawb kev ua haujlwm machining mus rau qib tom ntej. Nrog rau lub tshuab laum carbide hom MSK hauv lawv cov khoom siv, cov kws kho tshuab tuaj yeem ua ntau yam haujlwm machining nrog kev ua tau zoo thiab kev ua haujlwm zoo.

Lub sijhawm tshaj tawm: Plaub Hlis-26-2024