95 ° Anti-Vibration High Speed Steel Internal Toolholder Rau CNC Lathe Carbide Inserts

Muab ob npaug rau xauv kom haum haum

Cov riam zoo thiab tsis zoo yog xaiv tau kom tau raws li cov kev xav tau sib txawv.

1060 ° kub quenching thiab hardening kho.

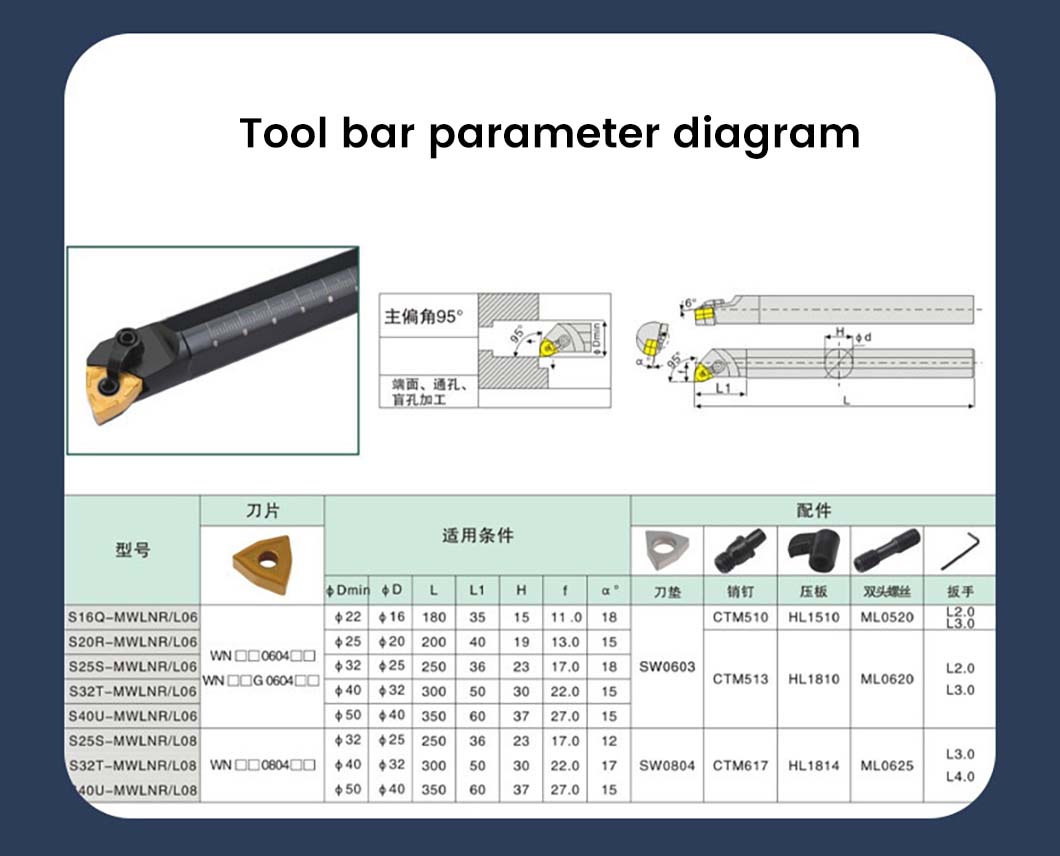

Specification

| Khoom npe | Composite puab qhov cuab yeej bar | Hom Tshuaj: | MSK |

| Khoom siv | Kev kub ceev steel | Khoom siv | Siab phaj / stud ntsia hlau / pin / shim / wrench |

Tool bar qauv Piv txwv li:

Kev ceev faj rau kev siv

Matching hniav, nruj haum.

FAQs

1. Kev puas tsuaj rov qab: (qhov no yog ib daim ntawv siv tau zoo)

Kev cuam tshuam: Lub workpiece loj me me hloov pauv lossis qhov ua tiav ntawm qhov chaw txo qis.

Yog vim li cas: Txoj kab ceev yog siab dhau thiab lub cuab yeej siv tau mus txog.

Kev ntsuas: Kho cov txheej txheem kev ua haujlwm, xws li txo cov kab nrawm thiab siv cov hniav nrog kev hnav siab dua.

2. Cov teeb meem tawg: (daim ntawv tsis zoo)

Impact: Lub workpiece loj los yog nto tag hloov dheev, sparks thiab burrs yog generated rau saum npoo. Ua rau: Kev teeb tsa tsis tsim nyog, kev xaiv cov khoom siv hniav tsis tsim nyog, kev ua haujlwm tsis zoo, tsis ruaj khov hniav clamping. Kev ntsuas: Txheeb xyuas seb qhov ntsuas qhov ntsuas puas tsim nyog, xaiv cov cuab yeej sib raug raws li cov khoom siv ua haujlwm,

3. Kev puas tsuaj loj: (daim ntawv cuam tshuam tsis zoo)

Kev cuam tshuam: Tam sim ntawd thiab qhov tshwm sim tsis tau xav txog, ua rau cov khoom siv cov khoom siv los yog cov khoom ua haujlwm tsis zoo thiab cov khoom seem. Ua rau: Tsis raug machining parameter teeb, vibrating workpiece los yog hniav tsis ntsia rau hauv qhov chaw. Kev ntsuas: Teem tsim nyog machining tsis, txo tus nqi pub thiab txo cov chips, xaiv cov machining cov hniav sib xws kom ntxiv dag zog rau cov khoom ua haujlwm thiab cov hniav.

4. Ua-up ntug

Kev cuam tshuam: qhov loj me me ntawm qhov chaw ua haujlwm tsis zoo, qhov tsis zoo ntawm qhov ua tiav, lint lossis burrs ntawm qhov chaw ua haujlwm. Ua rau: txiav ceev heev, pub tsawg dhau, hniav / tsis ntse txaus. Kev ntsuas: nce txiav ceev, pub tus nqi thiab siv cov hniav ntse dua.

Vim Li Cas Xaiv Peb

Hoobkas Profile

Txog Peb

FAQ

Q1: Peb yog leej twg?

A1: Founded hauv 2015, MSK (Tianjin) Txiav Technology CO.Ltd tau loj hlob tsis tu ncua thiab dhau Rheinland ISO 9001

authentication.Nrog German SACCKE high-end tsib-axis sib tsoo chaw, German ZOLLER rau-axis cuab yeej tshuaj xyuas chaw, Taiwan PALMARY tshuab thiab lwm yam khoom siv thoob ntiaj teb advanced manufacturing, peb tau cog lus los ua high-end, kws tshaj lij thiab siv tau zoo CNC cuab yeej.

Q2: Koj puas yog tuam txhab lag luam lossis chaw tsim khoom?

A2: Peb yog lub Hoobkas ntawm cov cuab yeej carbide.

Q3: Koj puas tuaj yeem xa cov khoom xa tuaj rau peb tus xa khoom hauv Suav teb?

A3: Yog, yog tias koj muaj Forwarder hauv Suav teb, peb yuav zoo siab xa cov khoom rau nws.Q4: Cov nqe lus them nqi dab tsi tuaj yeem lees txais?

A4: Feem ntau peb txais T / T.

Q5: Koj puas txais OEM xaj?

A5: Yog lawm, OEM thiab customization muaj, thiab peb kuj muab kev pabcuam luam ntawv.

Q6: Vim li cas koj yuav tsum xaiv peb?

A6: 1) Tus nqi tswj - kev yuav khoom zoo ntawm tus nqi tsim nyog.

2) Cov lus teb ceev ceev - tsis pub dhau 48 teev, cov neeg ua haujlwm tshaj lij yuav muab cov lus qhia rau koj thiab hais txog koj cov kev txhawj xeeb.

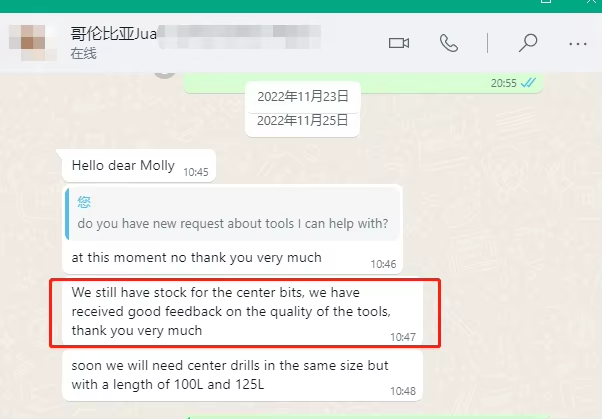

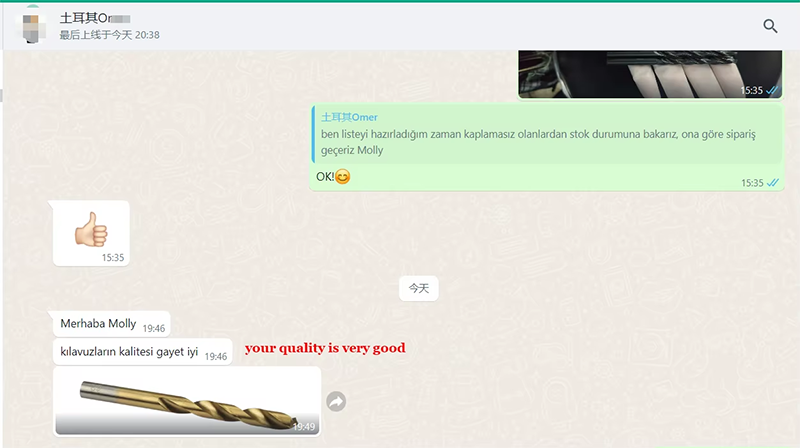

3) Zoo siab - Lub tuam txhab ib txwm ua pov thawj nrog lub siab dawb paug tias cov khoom nws muab yog 100% zoo.

4) Kev pab cuam tom qab muag thiab kev taw qhia kev lag luam - Lub tuam txhab muab kev pabcuam tomqab muag thiab kev cob qhia txuj ci raws li cov neeg siv khoom xav tau thiab xav tau.