Ithuluzi Lokusika I-Tungsten Carbide Dovetail Milling

Yonke into yenziwe ngensimbi ye-tungsten esezingeni eliphezulu, enobulukhuni obuphezulu kanye nokumelana nokuguguleka okuphezulu. Ukusetshenziswa kwezinto zensimbi ye-alloy esebenza kahle, enokumelana okuhle nokuzamazama komhlaba. Yenziwe ngemigoqo yensimbi ye-tungsten emisha ecolekile, enokumelana nokuguguleka okuphezulu kanye namandla. Ingummese we-dovetail osezingeni eliphezulu wokusetshenziswa kokusika okusheshayo nokuqina okuphezulu. Ingenza ukucubungula okusheshayo ensimbi engagqwali, i-aluminium alloy, insimbi ephonswe kanye nezinye izinto ezingaphansi kwe-HRC55 (kufaka phakathi i-HRC55). Umshini, ukunciphisa inani lezinguquko zamathuluzi kanye nokuthuthukisa ukusebenza kahle.

Inzuzo:

Isebenza kahle futhi sikhetha insimbi ye-tungsten esezingeni eliphezulu enobulukhuni obuphezulu kanye nokumelana nokuguguleka okuphezulu

Ukwakhiwa komshini oqondile, ukugaya kahle. Ukucubungula kahle, ukunciphisa ama-burrs ekucubungulweni komkhiqizo - ukushelela okuphezulu

Ukulawulwa kwekhwalithi okuqinile, ukunemba okuphezulu kanye nemikhiqizo eqediwe ebukhali

Isici:

1. Ama-engeli abukhali athuthukisa kakhulu ukusebenza kahle kokusika

2. Umklamo oqondile we-groove, ukususwa kwe-chip okubushelelezi ngaphandle kokunamathela kummese

3. Gwema umoya ngokufanele futhi wandise isikhathi sokuphila kwamathuluzi

4. Qinisa ukuqina komphetho osikiwe, futhi ibhande lomphetho we-arc lihamba kahle emphethoni ohlangothini obukhali futhi lisuse ngempumelelo i-burr.

5. Umsele wokususa ama-chip amakhulu unciphisa amandla, futhi ukusika kushelela kakhudlwana, kufeza ukusebenza kahle kakhulu komshini, futhi umsebenzi uqondile futhi umangalisa kakhudlwana.

| Uhlobo | Umsiki Wokugaya we-Tungsten Dovetail | Izinto | Insimbi ye-Tungsten |

| Izinto Zokusebenza | Insimbi engagqwali, i-aluminium, insimbi edayiwe, insimbi ephothiwe, i-aluminium alloy, insimbi ye-alloy, i-titanium alloy, njll. | Ithuluzi lomshini elisebenzayo | Isikhungo somshini we-CNC, ithuluzi lomshini we-CNC, umshini wokuqopha, umshini wokuqopha, umshini wesivinini esikhulu |

| Iphakheji Yezokuthutha | Ibhokisi | Umtshingo | 3/4 |

| Ukugqoka | No | Ubulukhuni | <=55 |

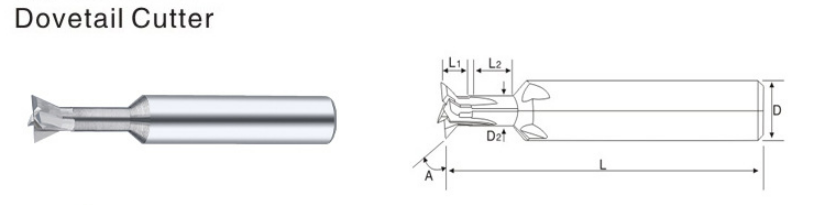

| Ububanzi beFlute (mm) | D2(mm) | I-L2(mm) | Ukuphakama kweFlute (mm) | Ububanzi be-Shank(mm) | Ubude obuphelele (mm) | Ama-Flute |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 | 20 | 75 | 4 |

Sebenzisa:

Kusetshenziswa kabanzi emikhakheni eminingi

Ukukhiqiza Izindiza

Ukukhiqizwa Kwemishini

Umkhiqizi wemoto

Ukwenza isikhunta

Ukukhiqiza Ugesi

Ukucubungula nge-lathe