Intuthuko yokukhiqiza egxile ezintweni ezintsha zokubhoboza ukugeleza (ezaziwa nangokuthii-drill bit yokungqubuzana kokushisas noma i-flowdrill) iguqula indlela izimboni ezidala ngayo imicu eqinile nethembekile ensimbini encane kanye nasepayipini. Lobu buchwepheshe obusekelwe ekungqubuzaneni buqeda isidingo sokubhoboza nokuthepha kwendabuko, okunikeza izinzuzo ezinkulu emandleni, isivinini, kanye nokusebenza kahle kwezindleko, ikakhulukazi emikhakheni yezimoto, yezindiza kanye neye-elekthronikhi.

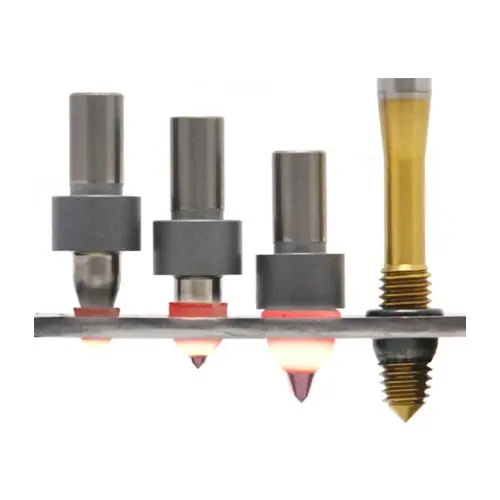

Ukuqamba okuyinhloko kusenqubo eyingqayizivele eqhutshwa yilezi zingcezu ezikhethekile. Ngokungafani nezimbobo ezivamile ezisika futhi zisuse izinto, ingcezu yokubhoboza egelezayo ikhiqiza ukushisa okukhulu ngokuhlanganiswa kwesivinini esikhulu kakhulu sokujikeleza kanye nokucindezela kwe-axial okulawulwayo. Njengoba ithiphu le-tungsten carbide elibunjwe ngendlela ekhethekile lithinta indawo yokusebenza, ukungqubuzana kushisa ngokushesha insimbi engaphansi - ngokuvamile insimbi, insimbi engagqwali, i-aluminium, noma i-alloys yethusi - esimweni sayo sepulasitiki (cishe ama-600-900°C kuye ngezinto).

Lokhu kuhlanganiswa kwe-bushing kuyisici esibalulekile. Ngokuvamile kwandisa ubukhulu bokuqala bezinto eziyisisekelo ngokuphindwe kathathu. Isibonelo, ukufaka intambo ephepheni elinobukhulu obungu-2mm kuholela ekholaleni eqinile engu-6mm ubude. Lokhu kwandisa kakhulu ukujula kokubandakanyeka kwentambo ngaphezu kwalokho obekungenzeka ngobukhulu bezinto zokusetshenziswa kuphela.

Ngemva kokwakheka kwe-bushing, inqubo ivame ukuqhubeka ngaphandle kokuphazamiseka. Ukuthepha okujwayelekile kulandelai-flow drill bit, kungaba ngokushesha emjikelezweni womshini ofanayo (emishinini ehambisanayo) noma ekusebenzeni okulandelayo. Impompi inquma imicu eqondile ngqo ebhushini elisha elakhiwe, elinodonga olujiyile. Njengoba ibhushi liyingxenye yesakhiwo sokuqala sezinhlamvu zezinto, hhayi into eyengeziwe, imicu ephumayo inokunemba okuphezulu okuphezulu kanye namandla aphezulu.

Izinzuzo Eziyinhloko Zokugqugquzela Ukwamukelwa:

Amandla Angenakuqhathaniswa Ezinto Ezincane: I-bushing engu-3x inikeza ukuhlanganiswa kwentambo okungcono kakhulu uma kuqhathaniswa nokuthinta ukujiya kwesisekelo ngqo noma ukusebenzisa ama-insert.

Isivinini Nokusebenza Kahle: Kuhlanganisa ukwenza imigodi nokwakheka kwe-bushing kube umsebenzi owodwa oshesha kakhulu (ngokuvamile imizuzwana ngomgodi ngamunye), kususa ukubhoboza okuhlukile, ukususa ukubhoboza, kanye nezinyathelo zokufaka zokufaka.

Ukonga Izinto: Awekho ama-chip akhiqizwayo ngesikhathi sokubhoboza ukugeleza, okunciphisa imfucuza yezinto.

Amajoyinti Avaliwe: Izinto ezisusiwe zigeleza ngokuqinile emgodini, ngokuvamile zidala ijoyinti elingavuzi elifanele ukusetshenziswa koketshezi noma ingcindezi.

Ukunciphisa Amathuluzi: Kuqeda isidingo samakinati, ama-weld nuts, noma ama-riveted inserts, okwenza kube lula ama-BOM kanye ne-logistics.

Inqubo Yokuhlanza: Ama-chips amancane futhi asikho isidingo sokusika uketshezi ezinhlotsheni eziningi (ukugcoba ngezinye izikhathi kusetshenziselwa impilo encane noma izinto ezithile).

Izinhlelo Zokusebenza Ziyanda: Ubuchwepheshe bukhula ngokushesha lapho izinto ezincane ezilula zidinga ukuxhumana okuqinile okunezintambo:

Izimoto: Amathreyi ebhethri lemoto kagesi, izingxenye zeshasi, amabhuleki, izinhlelo zokukhipha ugesi, ozimele bezihlalo.

Izindiza: Amaphaneli angaphakathi, amapayipi okuhambisa umoya, amabhuleki esakhiwo alula.

Izinto zikagesi: Ama-server racks, amaphaneli okuvala, ama-heat sink.

I-HVAC: Ukuxhumeka kwepayipi lensimbi eshidi, amabhuleki.

Ifenisha Nezinto Zikagesi: Ozimele besakhiwo abadinga izindawo zokubopha ezifihliwe neziqinile.

Abakhiqizi bezingcezu zokubhoboza ukugeleza bayaqhubeka nokuthuthukisa amajiyometri, ukumbozwa, kanye nokwakheka kwezinto ukuze bandise impilo yamathuluzi, bathuthukise ukusebenza kuma-alloy athuthukile, futhi bathuthukise inqubo yokwenza izinto ngokuzenzakalela. Njengoba izimboni ziphishekela ngokungaphezi ukukhanyisa kanye nokusebenza kahle kokukhiqiza, ukubhoboza ukungqubuzana kokushisa, okunikezwa amandla yi-innovativei-flowdrilli-bit, izibonakalisa iyisisombululo esibalulekile sokudala imicu esebenza kahle lapho yayingakaze ingenzeki khona noma ingasebenzi. Isikhathi sokulwa nemicu ebuthakathaka emashidini amancane sithatha indawo yamandla nobulula bemicu eyakhiwe ukungqubuzana.

Isikhathi sokuthunyelwe: Julayi-30-2025