Uma kukhulunywa ngokusebenza ngensimbi, ukunemba kubalulekile. Kungakhathaliseki ukuthi unguchwepheshe wemishini onolwazi noma ungumthandi we-DIY, ukuba namathuluzi afanele kubalulekile ukuze ufinyelele imiphumela oyifunayo. Elinye ithuluzi elithole ukuthandwa eminyakeni yamuva yilelii-burr drill bitKule bhulogi, sizohlola ukuthi yiziphi izingcezu zokubhoboza zensimbi, izinhlobo zazo ezahlukahlukene, nokuthi ungayikhetha kanjani ingcezu yokubhoboza ye-burr efanele iphrojekthi yakho.

Iyini i-burr drill bit?

I-burr drill bit, eyaziwa nangokuthi i-rotary burr, iyithuluzi lokusika elisetshenziswa kakhulu ekubumbeni, ekugayeni nasekususeni izinto ezindaweni eziqinile, okuhlanganisa nezinsimbi. Ngokuvamile zenziwa ngensimbi enesivinini esikhulu (i-HSS) noma i-carbide ukuze zimelane nobunzima bokusebenza kwensimbi. Ama-burr drill bit eza ngezindlela ezahlukene nobukhulu, okwenza abe ngamathuluzi asebenziseka ngezindlela eziningi, kusukela ekususeni i-burr kuya ekuqopheni.

Izinhlobo ze-Metal Burr Drill Bit

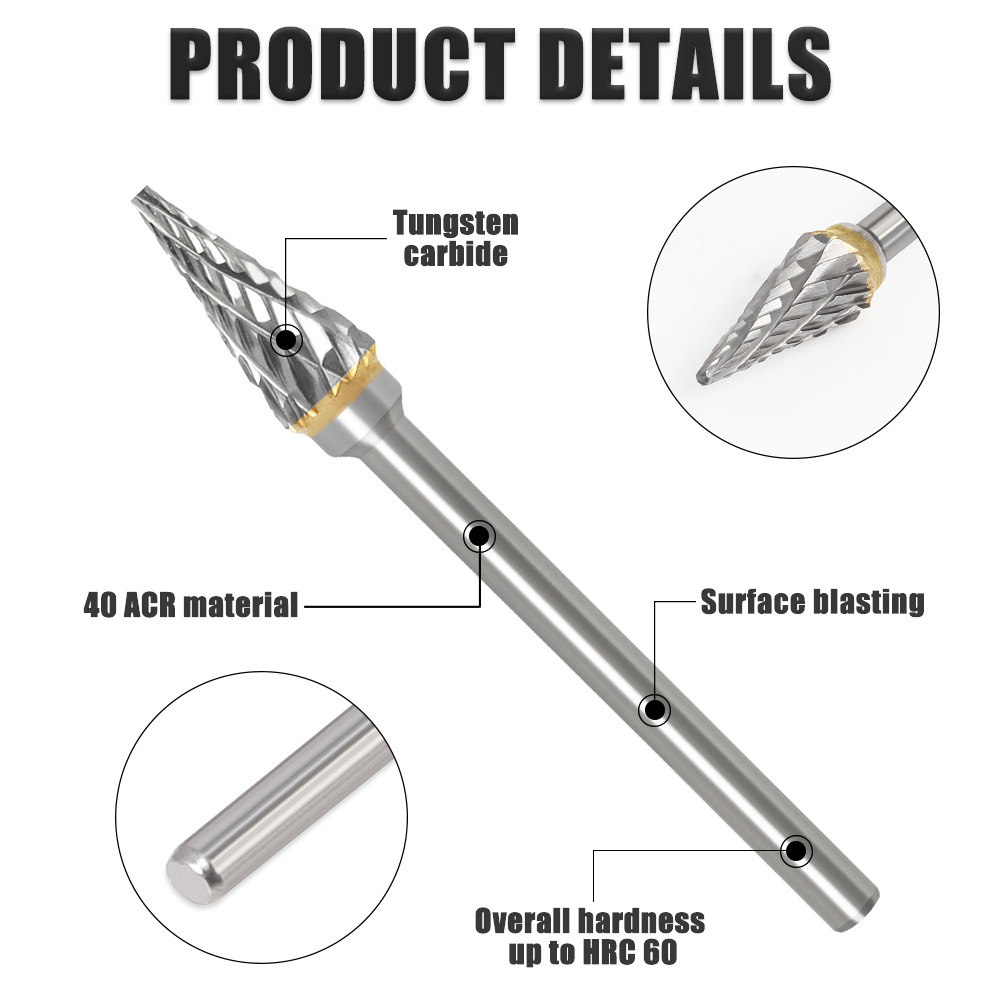

1. Ama-Tungsten Carbide Burrs: Lawa amanye ama-burr bits ahlala isikhathi eside emakethe. I-Tungsten carbide yaziwa ngokuqina kwayo kanye nokumelana nokuguguleka, okwenza la ma-burr afanele ukusetshenziswa kakhulu. Alungele ukusika, ukubumba, kanye nokugaya izinsimbi eziqinile njengensimbi engagqwali kanye ne-titanium.

2. Ama-Burr Ensimbi Esheshayo (i-HSS): Ama-Burr e-HSS ayinketho engabizi kakhulu uma kuqhathaniswa nama-carbide burr. Nakuba engase angapheli isikhathi eside, afaneleka ezinsimbini ezithambile futhi angasetshenziswa ngezinjongo ezijwayelekile. Ama-Burr e-HSS avame ukusetshenziselwa amaphrojekthi abantu abathanda izinto zokuzijabulisa kanye nemisebenzi elula yokusebenza ngensimbi.

3. Ama-Aluminium Oxide Burrs: Aklanyelwe ngqo ukwenziwa kwe-aluminium, la ma-burrs ane-coating ehlukile evimbela izinto ukuthi zinganamatheli ethuluzini. Alungele ukudala ukuqeda okubushelelezi ezindaweni ze-aluminium ngaphandle kwengozi yokuvaleka.

4. Ama-Diamond Burr: Ukuze kwenziwe umsebenzi onembile, ama-diamond burr ayindlela ekhethwayo. Ngenxa yekhono lawo lokudala imininingwane emihle kanye nezindawo ezibushelelezi, avame ukusetshenziswa ekwenzeni ubucwebe kanye nokusebenza kwensimbi okuyinkimbinkimbi. Ama-diamond burr angasetshenziswa ezintweni ezahlukahlukene, kufaka phakathi insimbi, ingilazi, kanye ne-ceramics.

Khetha i-burr drill bit efanele

Uma ukhetha i-deburring drill bit yokusebenza ngensimbi, cabanga ngalokhu okulandelayo:

- Izinto: Uhlobo lwensimbi oyisebenzisayo luzonquma uhlobo lwe-burr bit oludingayo. Ngezinsimbi eziqinile, khetha ama-Tungsten Carbide burrs, kuyilapho ama-HSS burrs efanelekile ezintweni ezithambile.

- Isimo:Izingcezu ze-Burrziza ngezimo ezahlukahlukene, kufaka phakathi eziyisilinda, eziyindilinga, kanye nelangabi. Isimo osikhethayo sizoncika emsebenzini othize okhona. Isibonelo, ama-cylindrical burrs amahle kakhulu ekusikeni okuqondile, kanti ama-spherical burrs amahle kakhulu ekwakheni imiphetho eyindilinga.

- USAYIZI: Ama-bits okubhoboza e-Burr eza ngobukhulu obuhlukahlukene, futhi ubukhulu obukhethayo buzothinta ukunemba komsebenzi. Ama-bits amancane angcono emsebenzini omuhle, kanti ama-bits amakhulu angasusa izinto ngokushesha.

- Isivinini: Isivinini osebenzisa ngaso ithuluzi lakho elijikelezayo sizothinta nokusebenza kahle kwe-burr drill yakho. Isivinini esiphezulu ngokuvamile singcono ezintweni eziqinile, kanti isivinini esiphansi singase sibe ngcono ngezinsimbi ezithambile ukuvimbela ukushisa ngokweqile.

Ekuphetheni

Izingcezu ze-Burr zensimbiUkusebenza kungamathuluzi abalulekile okwandisa ukunemba nokusebenza kahle kwamaphrojekthi akho. Ngokuqonda izinhlobo ezahlukene zama-burr drill bits atholakalayo nokuthi ungakhetha kanjani efanele izidingo zakho ezithile, ungafinyelela imiphumela yekhwalithi yobungcweti emisebenzini yakho yokusebenza ngensimbi. Kungakhathaliseki ukuthi ususa ama-burr emaphethelweni, ubumba insimbi, noma udala imiklamo eyinkimbinkimbi, ukutshala imali ku-burr drill bit efanele ngokungangabazeki kuzophakamisa ubuciko bakho. Ujabule ngomsebenzi wensimbi!

Isikhathi sokuthunyelwe: Jan-02-2025