Ezweni elisheshayo lokukhiqizwa kwezinto zikagesi, lapho ukunemba kwezinga le-micron kuchaza khona impumelelo, ukwethulwa kwe-Next-Gen PCB Board Drill Bits kuphawula igxathu elikhulu ekwakhiweni kwebhodi lesifunda. Yakhelwe ukubhoboza, ukuqopha, kanye nokwenza i-micromachining kumabhodi esifunda aphrintiwe (ama-PCB) kanye nezinye izinto ezincane kakhulu, lezi Tungsten SteelI-Mini Drill PCBAmathuluzi ahlanganisa izinto zezinga lezindiza nobuchwepheshe bokuzinza kokuzamazama komhlaba ukuze kuchazwe kabusha ukusebenza kahle kanye nokuphila isikhathi eside ekukhiqizweni okuphezulu.

Ubuchwepheshe Bokwenza Izinto Kahle: Kungani Insimbi Ye-Tungsten Ibalulekile

Enhliziyweni yalezi zingcezu zokubhoboza kukhona i-tungsten carbide (WC) emsulwa kakhulu, into ekhethiwe ngenxa yokuhlanganiswa kwayo okungenakuqhathaniswa kobulukhuni (HRA 92), ukumelana nokuguguleka, kanye nokuqina kwesakhiwo. Ngokungafani nokubhoboza okuvamile kwe-HSS (High-Speed Steel), lokhu kwakheka kwensimbi ye-tungsten kunikeza:

Isikhathi Sokuphila Esiyi-3X Eside: Imelana nemijikelezo yokubhoboza engaphezu kuka-15,000 kumabhodi e-fiberglass e-FR-4 ngaphandle kokuwohloka komphetho.

Isakhiwo Sezinhlamvu Ezincane: Izinhlayiya ze-carbide ezingaphansi kuka-0.5µm ziqinisekisa imiphetho yokusika ebukhali njenge-razor, zifinyelela ububanzi bemigodi emincane njengo-0.1mm ngokubekezelelana okungu-±0.005mm.

Umklamo Olwa Nokuqhekeka: I-geometry ye-shank eqinisiwe ivimbela ukuqhekeka ngesikhathi sokusebenza kwe-RPM ephezulu (30,000–60,000), ngisho nasezintweni ze-PCB ezigcwele i-ceramic eziqhekekile.

Ukuhlolwa kweqembu lesithathu yi-Precision Machining Institute of Technology kuqinisekisa ukuthi lawa ma-bits agcina ukuqeda kobuso okungu-Ra 0.8µm ngemuva kwemigodi eyi-10,000 - isici esibalulekile sobuqotho besignali yemvamisa ephezulu kumadivayisi e-5G kanye ne-IoT.

Ukuzinza Kwesimo Sezwe: Ukusika Ngaphandle Kokuyekethisa

Ukubhoboza kwe-PCB kudinga ukuzinza okuphelele ukuze kuvinjelwe "ukuhamba" noma ukungalungi kwemigodi. I-Proprietary Seismic Blade Edge Design ibhekana nalokhu ngale ndlela:

I-Asymmetric Flute Geometry: Ilinganisela ukuphuma kwe-chip kanye nokunciphisa ukudlidliza, inciphisa amandla aseceleni ngo-40%.

I-Nano-Coated Helix Angle: I-30° helix ene-TiAlN coating inciphisa ukwakheka kokushisa (<70°C) ngesikhathi sokusebenza okuqhubekayo.

Ama-Anti-Resonance Grooves: Amashaneli amancane aqoshiwe nge-laser aphazamisa amaza e-harmonic, aqinisekisa ukunemba kwendawo ngaphakathi kwama-5µm kuma-PCB anezingqimba eziyi-10.

Ekuhlolweni kokucindezeleka kokubhoboza imigodi engu-0.3mm ngamabhodi ambozwe nge-aluminium angu-2mm, lawa ma-bits abonise ukuphambuka okungenalutho emijikelezweni engu-500 elandelanayo - into engenakuqhathaniswa nabancintisana nabo.

Izicelo Kuzo Zonke Izimboni

Ama-elekthronikhi Abathengi

Kwabakhiqizi bebhodi lomama le-smartphone:

Ama-Micro-Vias angu-0.2mm: Kufinyelelwe amazinga okukhiqiza angu-99.9% kumabhodi e-HDI anezingqimba ezingu-12.

Amanani Okuphakela Okusheshayo angu-20%: Asebenza ngokunciphisa ukungqubuzana kanye nokuvaleka kwama-chip.

Izimoto zikagesi

Ekukhiqizweni kwemodyuli yamandla e-EV:

Ukuthembeka Kwemigodi Edlulayo: Kugcinwe ukuqhubeka kukagesi okungu-100% ezindaweni ezisebenzisa ukushisa ezinobukhulu obungu-1.6mm.

Ukusebenza Okungenawo Ukupholisa: Amandla okubhoboza okomile agwema ukungcola ezinhlelweni zokuphatha amabhethri ezivaliwe.

Izindiza kanye Nokuvikela

Ukubhoboza imigodi engu-0.15mm kumasekethe e-polyimide flex:

Akukho Kuhlukaniswa Kwemvelo: Ngisho nasezindaweni ezinomswakama ophezulu ezingama-200°C.

Ukuhlela i-EMI Shield: Ukuqopha ngokunemba kwezingqimba zokuvikela ze-RF ezisekelwe ku-graphene.

Imininingwane Yobuchwepheshe

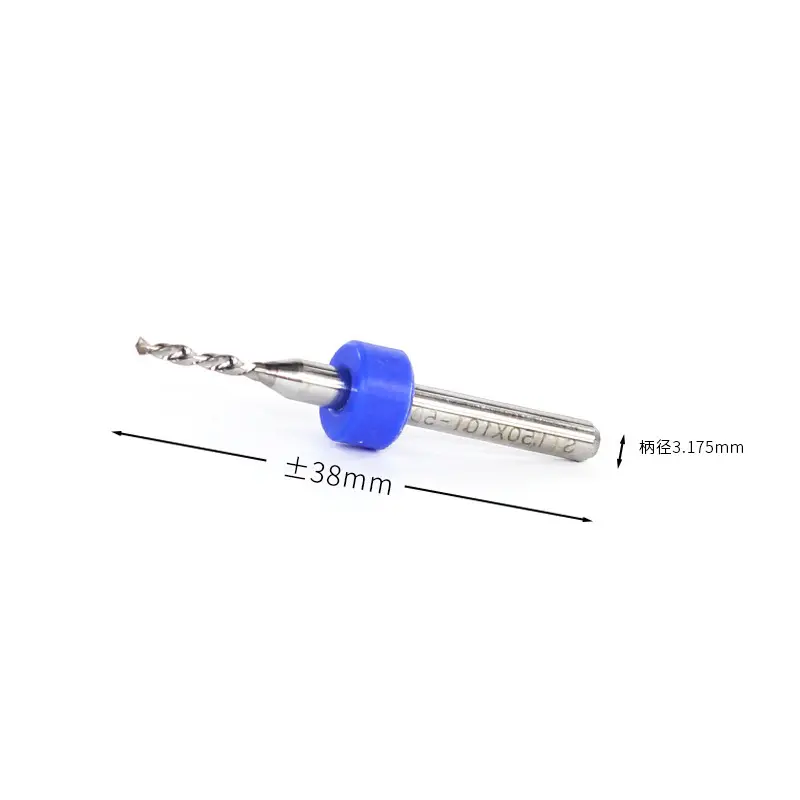

Ububanzi Bebanga: 0.1mm–3.175mm (0.004"–1/8")

Uhlobo lwe-Shank: Ukuhambisana okujwayelekile okungu-3.175mm (1/8") noma i-collet ye-ER yangokwezifiso

Izinketho Zokumboza: I-TiN (igolide), i-TiCN (eluhlaza okwesibhakabhaka), noma i-Diamond-Like Carbon (DLC)

I-RPM Ephezulu: 80,000 (kuncike kububanzi)

Ukuhambisana: Imishini yokubhoboza ye-CNC, imishini yokubhoboza ye-PCB ezenzakalelayo, amathuluzi ajikelezayo aphathwa ngesandla

Ukusetshenziswa Kabusha Kwezindleko

Ukuhlaziywa kwezindleko nezinzuzo okwenziwe ngumenzi we-PCB ohamba phambili waseTaiwan kwembule:

Imali Yokonga Yonyaka engu-$18,500: Ukushintsha ama-drill bit okuncishisiwe (kusukela kumasethi angu-12 kuya kwangu-4 ngonyaka).

Ukunciphisa Amandla okungu-15%: Izidingo eziphansi ze-spindle torque.

Akukho Ukulungiswa: Kususwe u-$220k ngonyaka emabhodini alahliwe avela ekuzulazuleni kwe-drill.

Ukuzinza Okwakhelwe Ngaphakathi

Ukupakisha Okungasetshenziswa Kabusha: Amathreyi e-foam abola ngo-100%.

Ukuhambisana ne-RoHS kanye ne-REACH: Akukho lead, i-cadmium, nezinye izinto eziyingozi.

Impilo Yamathuluzi Enwetshiwe: Ukusetshenziswa kwe-tungsten okuphansi ngo-60% uma kuqhathaniswa nokubhola okujwayelekile.

Ubufakazi Bomsebenzisi

"Ukushintshela kulezi zingcezu zensimbi ye-tungsten kwaba ushintsho," kusho uHiroshi Tanaka, uMphathi Wokukhiqiza kumkhiqizi wezinzwa oseKyoto. "Sibhoboza imigodi engu-20,000 ngokushintsha ngakunye ngaphandle kokushintsha kwamathuluzi - into engacabangeki ngama-drill ethu amadala e-HSS. Umklamo wokuzamazama komhlaba wodwa unciphisa ukwenqatshwa kwethu kwemigodi ngo-95%.

Kungani Kufanele Ukhethe Lezi Zingcezu Zokubhoboza Ibhodi Le-PCB?

Ukunemba Okungaphuki: Kokunemba okufana ne-laser kumabhodi e-high-density interconnect (HDI).

Isivinini Esingenalo Uzinikelo: Bhoboza imigodi engu-0.3mm emigodini engu-400 ngomzuzu ngaphandle kokwehlisa ikhwalithi yomphetho.

Ukuhambisana Okubanzi: Kusebenza ne-FR-4, i-Rogers, i-aluminium, ngisho nama-laminate aqiniswe ngengilazi.

Umklamo Oqinisekisa Ikusasa: Ulungele izinto ze-PCB zesizukulwane esilandelayo njenge-dielectric ezingenayo i-halogen kanye ne-ultra-low-loss.

Isiphetho

Embonini lapho yonke i-micron inquma khona inzuzo kanye nokusebenza kahle, lezi Tungsten SteelAmabhithi Okubhoboza Ibhodi le-PCBzingaphezu nje kwamathuluzi – ziyinzuzo yamasu. Ngokuhlanganisa isayensi yezinto ezibonakalayo nobunjiniyela bokuzinza, zinika amandla abakhiqizi ukuthi badlule imingcele ye-miniaturization ngenkathi benciphisa

Isikhathi sokuthunyelwe: Mashi-21-2025