Emkhakheni wokusebenza ngokunemba, ukukhetha ithuluzi lokusika kungathinta kakhulu ikhwalithi yomkhiqizo oqediwe, ukusebenza kahle kwenqubo yokukhiqiza kanye nokusebenza kahle kwezindleko zokukhiqiza. Phakathi kwala mathuluzi, ama-insert okujika adlala indima ebalulekile ekufinyeleleni imiphumela emihle kakhulu. Kule bhulogi, thina'Ngizohlolaama-insert amahle kakhulu okujika emakethe, izici zazo, kanye nendlela yokukhetha i-insert efanele izidingo zakho ezithile zomshini.

Funda ngokuphendula ama-insert

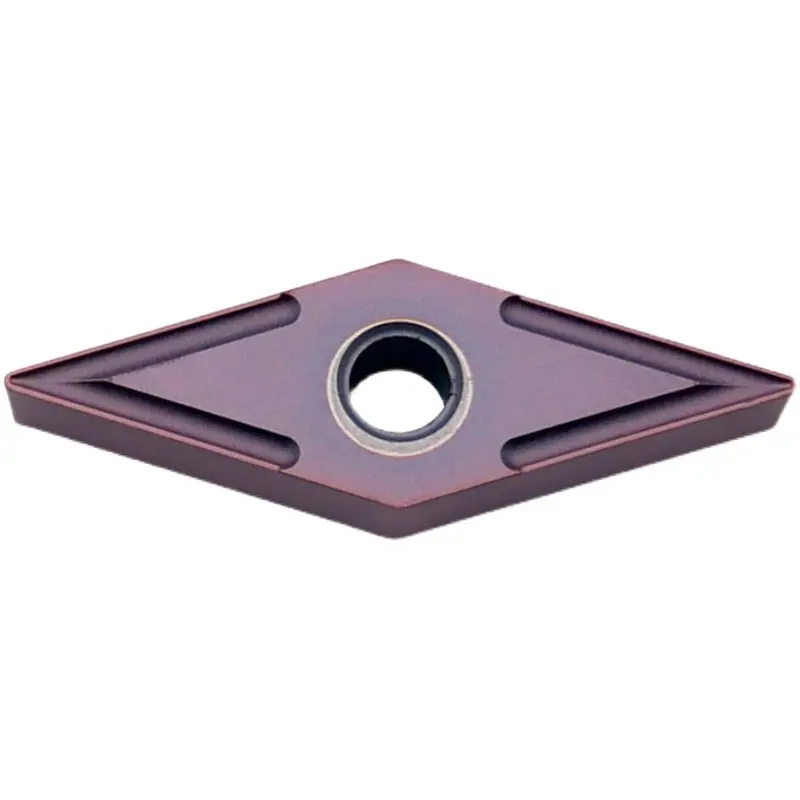

Ama-turning inserts amathuluzi amancane okusika angashintshwa asetshenziswa kuma-lathe nama-lathe ukuze akhe futhi aqedele izinto ezifana nensimbi, ipulasitiki kanye nokhuni. Afika ngezindlela ezahlukene, osayizi kanye nezinto zokwakha, ngayinye yenzelwe ukusetshenziswa okuthile. I-turning insert efanele ingathuthukisa ukusebenza kokusika, ithuthukise ukuqeda kwendawo futhi yandise isikhathi sokuphila kwamathuluzi, ngakho-ke ukukhetha inketho engcono kakhulu yephrojekthi yakho kubalulekile.

Izici Eziyinhloko Zokufaka Okujika Okuhle Kakhulu

1. Ukwakheka Kwezinto:Izinto ezisetshenziswa ekuphenduleni kwakho zingenye yezinto ezibaluleke kakhulu okufanele uzicabangele. Izinto ezivamile zifaka phakathi i-carbide, i-ceramics, i-cermets, kanye nensimbi yesivinini esikhulu (i-HSS). Izinto ezisetshenziswayo ze-carbide zithandwa ngenxa yokuqina kwazo kanye nokumelana nokuguguleka, okwenza zifaneleke ekusetshenzisweni kwemishini yesivinini esikhulu. Ngakolunye uhlangothi, ama-blade e-ceramic afanele ukusetshenziswa kwezinga lokushisa eliphezulu.

2. UKUGQAQA:Izimbozo eziningi zokujika ziyambozwa ukuze kuthuthukiswe ukusebenza kwazo. Izimbozo ezifana ne-TiN (titanium nitride), i-TiAlN (titanium aluminium nitride) kanye ne-TiCN (titanium carbonitride) zingathuthukisa ukumelana nokuguguleka, zinciphise ukungqubuzana futhi zandise isikhathi samathuluzi. Khetha izimbozo ezimboziwe ukuze usebenze kangcono ezimweni ezinzima zomshini.

3. Ijiyometri:I-geometry ye-insert (kufaka phakathi ukuma kwayo, i-engela yokusika kanye nomklamo we-chipbreaker) idlala indima ebalulekile ekusebenzeni kwayo kokusika. Ama-rake blades amahle afanele izinto ezithambile, kuyilapho ama-rake blades angalungile afaneleka kangcono ezintweni eziqinile. Ngaphezu kwalokho, umklamo we-chip breaker ungasiza ukulawula ukugeleza kwe-chip nokuthuthukisa ukuqeda kobuso.

4. Usayizi Nokuma:Ama-insert okujika afika ngezindlela ezahlukahlukene, kufaka phakathi isikwele, unxantathu, kanye nesiyingi. Ukukhetha ukuma kuncike ekusebenzeni okuthile kokujika kanye ne-geometry yento yokusebenza. Isibonelo, ama-insert okujika ayisikwele ayasebenziseka futhi angasetshenziswa kokubili emisebenzini yokugoqa kanye neyokuqeda, kuyilapho ama-insert okujikelezayo efanelekile emisebenzini yokuqeda.

Imikhiqizo Ehamba Phambili kanye Nezitho Zabo Ezingcono Kakhulu Zokuguqula

1. I-Sandvik Coromant:Iyaziwa ngamathuluzi ayo okusika amasha, iSandvik inikeza uhla lwezingcezu zokujika ezisezingeni eliphezulu. Uchungechunge lwabo lwezingcezu ze-carbide ezifakiwe ze-GC luthandwa kakhulu ngenxa yokusebenza kwazo okuhlukahlukene kanye nokusebenza kwazo ezintweni ezahlukahlukene.

2. I-Kennametal:I-Kennametal ingenye ibhrendi ehamba phambili embonini yamathuluzi okusika. Uchungechunge lwabo lwe-KCP lokufakwa lwenzelwe imishini esheshayo futhi lunokumelana okuhle kakhulu nokuguguleka, okwenza kube yintandokazi phakathi kwabakhiqizi.

3. Amathuluzi kaWalter:Izithako zikaWalter zokujika zaziwa ngokunemba kwazo nokuqina kwazo. Uchungechunge lweWalter BLAXX lune-geometrics ethuthukisiwe kanye nezingubo zokugqoka ukuze kuthuthukiswe ukusebenza ngaphansi kwezimo ezinzima zomshini.

4. U-Iscar:I-Iscar'Ama-insert okujika aklanyelwe ukusebenza kahle kanye nokukhiqiza. Uchungechunge lwayo lwe-IC lunikeza izinhlobo ezahlukene zamajiyometri kanye nopende ukuze kufanelane nezinhlelo zokusebenza ezahlukahlukene.

Ekuphetheni

Ukukhetha i-insert yokujika engcono kakhulu kubalulekile ekufinyeleleni imiphumela emihle kakhulu yomshini wokugaya. Ngokucabanga ngezinto ezifana nokwakheka kwezinto, ukumbozwa, i-geometry, kanye nedumela lomkhiqizo, ungakhetha i-blade efanele izidingo zakho ezithile. Ukutshala imali kuma-insert okujika asezingeni eliphezulu akugcini nje ngokuthuthukisa ikhwalithi yomsebenzi wakho, kodwa futhi kwandisa umkhiqizo futhi kunciphisa izindleko eziphelele. Kungakhathaliseki ukuthi unguchwepheshe wemishini onolwazi noma umusha embonini, ukuqonda izici ze-insert zokujika kuzokunika amandla okwenza izinqumo ezinolwazi futhi uthathe amaphrojekthi akho omshini uwayise ezingeni elisha.

Isikhathi sokuthunyelwe: Disemba 11-2024