Umzamo ongapheli wokufuna izimoto ezilula, eziqinile, nezisebenza kahle, ikakhulukazi ngokukhula okukhulu kwezimoto zikagesi (ama-EV), ubeka ingcindezi enkulu ekukhiqizweni kwezimoto. Izindlela zendabuko zokwakha ukuxhumana okuqinile okunezintambo ngensimbi encane - okuyisisekelo semizimba yezimoto zanamuhla, ozimele, kanye nezindawo ezivalekile - zivame ukufaka izibambo ezengeziwe ezifana namakinati e-weld noma ama-rivet nuts. Lokhu kwethula ubunzima, isisindo, amaphuzu okwehluleka okungenzeka, kanye nezikhathi zomjikelezo ezihamba kancane. Faka i-Thermal Friction Drilling (TFD) kanye namathuluzi ayo akhethekile -I-Carbide Flow Drill Bits kanye nama-Thermal Friction Drill Bit Sets – ubuchwepheshe obushintsha ngokushesha imigqa yokukhiqiza izimoto ngokuzenzakalelayo ukudalwa kwezintambo ezihlanganisiwe, ezinamandla aphezulu ngqo ngaphakathi kwezinto ezincane.

Inselele Yokuzibopha Kwezimoto: Isisindo, Amandla, Isivinini

Onjiniyela bezimoto bahlala belwa nobunzima obufanayo. Izinsimbi ezincane nezinamandla aphezulu kanye ne-aluminium alloys kubalulekile ekunciphiseni isisindo semoto kanye nokuthuthukisa ukusebenza kahle kukaphethiloli noma ububanzi be-EV. Kodwa-ke, ukudala izintambo ezithwala umthwalo ezithembekile kulezi zingxenye ezincane kuyinkinga:

Ukuzibandakanya Okulinganiselwe: Ukuchofoza okujwayelekile ephepheni elincane kunikeza ukuzibandakanya okuncane kwentambo, okuholela ekuqineni okuphansi kokudonsa kanye nokuthambekela ekukhumuleni.

Ubunzima Obungeziwe Nesisindo: Ukushisela amantongomane, amantongomane e-clinch, noma amantongomane e-rivet engeza izingxenye, kudinga imisebenzi yesibili (ukushisela, ukucindezela), ukwandisa isisindo, nokufaka izindawo ezingaba khona zokugqwala noma izinkinga zokulawula ikhwalithi.

Izinkinga Zenqubo: Ukubhoboza okuhlukile, ukufakwa/ukunamathisela izibambo, kanye nezinyathelo zokuthepha zehlisa ijubane lemigqa yokukhiqiza ephezulu.

Ukushisa Nokuhlanekezela: Amantongomane okushisela akhiqiza ukushisa okukhulu, okungase kugobe amaphaneli amancane noma kuthinte izakhiwo zezinto eziku-Heat Affected Zone (HAZ).

Ukubhoboza Okugelezayos: Isixazululo Esizenzakalelayo Esisemgqeni

Ukubhola Okushisayo, okuhlanganiswe nezikhungo zokugaya ze-CNC, amaseli erobhothi, noma imishini ezinikele ye-multi-spindle, kunikeza impendulo ethokozisayo:

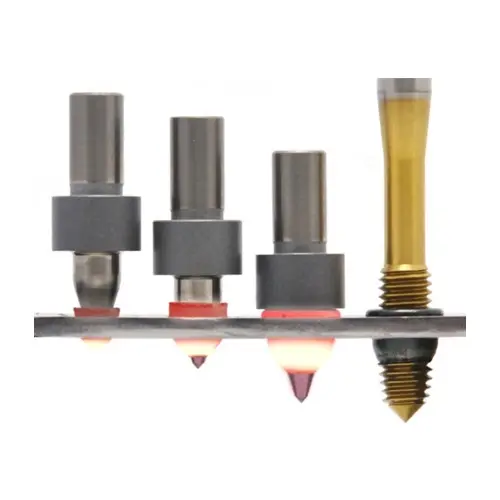

Amandla Okusebenza Okukodwa: Umlingo oyinhloko we-TFD ulele ekuhlanganiseni ukubhoboza, ukwakheka kwe-bushing, kanye nokusebenzisa umsebenzi owodwa ongenamthungo, ozenzakalelayo. I-Carbide Flow Drill Bit eyodwa, ejikeleza ngesivinini esikhulu (ngokuvamile i-3000-6000 RPM yensimbi, ephakeme kune-aluminium) ngaphansi kwamandla amakhulu e-axial, ikhiqiza ukushisa okukhulu kokungqubuzana. Lokhu kwenza insimbi ibe yipulasitiki, okuvumela i-geometry ehlukile ye-bit ukuthi igeleze futhi isuse impahla, yakha i-bushing engenamthungo, ehlanganisiwe cishe izikhathi ezintathu ubukhulu beshidi lokuqala.

Ukuthepha Ngokushesha: Njengoba i-Flow Drill ihoxa, kulandela ngokushesha ukuthepha okujwayelekile (ngokuvamile ku-tool holder efanayo ohlelweni lokushintshanisa ngokuzenzakalela noma i-spindle yesibili evumelanisiwe), kusika imicu enembile kakhulu kulesi sihlahla esisha esakhiwe, esinodonga olujiyile. Lokhu kuqeda ukuphathwa phakathi kokusebenza futhi kunciphisa kakhulu isikhathi somjikelezo.

Ukuhlanganiswa Kwerobhothi: Amasethi E-Thermal Friction Drill Bit afaneleka kakhulu ezingalweni zerobhothi. Amandla awo okwenza yonke inqubo yokudala intambo ngendlela eyodwa yamathuluzi (ukubhoboza phansi, ukwakha i-bushing, ukuhoxisa, ukuthepha phansi, ukuhoxisa) kwenza kube lula ukuhlela nokusebenza kwerobhothi. Amarobhothi angabeka ithuluzi ngokunembile phezu kwezakhiwo eziyinkimbinkimbi zomzimba noma izinhlangano ezincane (BIW).

Kungani Abakhiqizi Bezimoto Besebenzisa Ama-Flow Drills:

Amandla Entambo Akhuliswe Kakhulu: Lena inzuzo enkulu. Izintambo zibamba i-bushing ejiyile (isb., zakha i-bushing engu-9mm ubude kusuka ephepheni elingu-3mm), okuholela ekutheni amandla okudonsa nokukhumula avame ukwedlula lawo ama-weld nuts noma ama-rivet nuts. Lokhu kubalulekile ezingxenyeni ezibalulekile zokuphepha (izikhonkwane zebhande lesihlalo, izikhonkwane zokumiswa) kanye nezindawo ezinokudlidliza okuphezulu.

Ukunciphisa Isisindo Okuphawulekayo: Ukususa inathi yokuwelda, inathi ye-rivet, noma inathi ye-clinch ngokwayo kususa isisindo. Okubaluleke kakhulu, kuvame ukuvumela abaklami ukuthi basebenzise izinto zokulinganisa ezincane njengoba i-bushing eyakhiwe inikeza ukuqina kwendawo lapho kudingeka khona amandla, ngaphandle kokwengeza isisindo kwenye indawo. Amagremu alondolozwe ngokuxhumeka ngakunye anda ngokushesha emotweni.

Ukusebenza Kahle Kwenqubo Okungalingani kanye Nesivinini: Ukuhlanganisa imisebenzi emithathu ibe yizikhathi zomjikelezo owodwa wokusikeka. Umjikelezo ojwayelekile wokubhoboza ngokushisa kanye nokuthepha ungaqedwa ngemizuzwana emi-2-6, ngokushesha okukhulu kunokubhoboza okulandelanayo, ukubeka/ukushisela amantongomane, kanye nokuthepha. Lokhu kukhulisa ukusebenza kwemigqa yevolumu ephezulu.

Ikhwalithi Ethuthukisiwe Nokungaguquguquki: I-TFD ezenzakalelayo inikeza ukungaguquguquki okumangalisayo phakathi kwembobo nembobo. Le nqubo iphindaphindeka kakhulu ngaphansi kwemingcele elawulwayo ye-CNC noma yerobhothi, okunciphisa amaphutha abantu avamile ekubekweni kwamantongomane ngesandla noma ekushiseni. I-bushing eyakhiwe idala indawo ebushelelezi, evame ukuvalwa, ithuthukisa ukumelana nokugqwala kanye nokunamathela kopende.

Ubunzima Besistimu Ebunciphile Nezindleko: Ukususa iziphakeli zamantongomane ezihlukene, iziteshi zokushisela, izilawuli zokushisela, kanye nokuhlolwa kwekhwalithi okuhambisanayo kunciphisa izindleko zemishini yenhloko-dolobha, izidingo zesikhala saphansi, ubunzima bokulungisa, kanye nezinto ezisetshenziswayo (akukho cingo/igesi yokushisela, akukho mantongomane).

Ukuqina Okuthuthukisiwe Kwamalunga: I-integral bushing yakha ingxenye eqhubekayo yensimbi yezinto eziyisisekelo. Akukho bungozi bokuthi inathi ikhululeke, iphothe, noma iwe njengezibambo zomshini, futhi akukho ukukhathazeka nge-HAZ okufana nokushisela.

Ukuguquguquka Kwezinto Ezisetshenziswayo: Ama-Carbide Flow Drill Bits aphatha ngempumelelo izinto ezahlukahlukene ezimotweni zesimanje: insimbi ethambile, insimbi ye-High-Strength Low-Alloy (HSLA), i-Advanced High-Strength Steel (AHSS), ama-aluminium alloys (5xxx, 6xxx), kanye nezinye izingxenye ezingagqwali. Ukwembozwa kwamathuluzi (njenge-AlCrN ye-aluminium, i-TiAlN yensimbi) kuthuthukisa ukusebenza nokuphila.

Izicelo Eziyinhloko Zezimoto Zokwamukelwa Kokushayela:

Izivalo Namathileyi Ebhethri Le-EV: Mhlawumbe umshayeli omkhulu kunabo bonke. Lezi zakhiwo ezinkulu, ezinezindonga ezincane (ngokuvamile i-aluminium) zidinga amaphuzu amaningi aqinile, angavuzi ukuze zifakwe, zimboze, zipholise amapuleti, kanye nezingxenye zikagesi. I-TFD inikeza amandla adingekayo ngaphandle kokwengeza isisindo noma ubunzima. I-bushing evaliwe isiza ukuvimbela ukungena kwe-coolant.

I-Chassis & Subframes: Ama-bracket, amalungu ahlanganisiwe, kanye nama-suspension installing azuza emandleni e-TFD kanye nokumelana nokudlidliza ezinsimbini ezincane nezinamandla aphezulu.

Amafreyimu Nezindlela Zesihlalo: Izingxenye zokuphepha ezibalulekile ezidinga amandla aphezulu kakhulu okudonsa ama-anchor ebhande kanye nezindawo zokufaka eziqinile. I-TFD isusa izibambo ezinkulu kanye nokuphazamiseka kokushisela.

Umzimba Omhlophe (BIW): Amabhuleki ahlukahlukene, iziqiniseko, kanye nezindawo zokufaka ngaphakathi ngaphakathi kwesakhiwo semoto lapho amantongomane engeziwe eba nzima futhi ukushisela kungadingeki.

Izinhlelo Zokukhipha Umoya: Ama-hangers okufaka kanye nezinamathiselo zokuvikela ukushisa ensimbi engagqwali encane noma ensimbini eyenziwe nge-aluminium azuza embobeni evaliwe engagqwali kanye nokumelana nokudlidliza.

Amayunithi e-HVAC kanye ne-Ducting: Izindawo zokufaka kanye namaphaneli okufinyelela isevisi adinga izintambo eziqinile ezivalweni zensimbi ezincane.

Imfuneko ye-Carbide ku-TFD Yezimoto:

Ukusebenza kokukhiqiza izimoto kuthatha isikhathi eside, kudinga ukuthembeka okuphelele kwamathuluzi kanye nobude besikhathi. Ama-Carbide Flow Drill Bits awaxoxiswani. Amelana namazinga okushisa aphezulu okungqubuzana (ngokuvamile adlula u-800°C/1472°F esicongweni), isivinini esiphezulu sokujikeleza, kanye namandla amakhulu e-axial ahlangana nezinkulungwane zezikhathi ngokushintshwa ngakunye. Ama-substrate e-micro-grain carbide athuthukisiwe kanye nezingubo ezikhethekile (i-TiAlN, i-AlTiN, i-AlCrN) enzelwe izinto ezithile zezimoto, andisa impilo yamathuluzi futhi agcina ukwakheka kwe-bushing okuhambisanayo kanye nekhwalithi yembobo ebalulekile ezinqubweni ezenzakalelayo. I-Carbide Flow Drill Bits inakekelwe kahle.Isethi Yebhithi Yokubhoboza Okushisayoingacubungula izinkulungwane zemigodi ngaphambi kokudinga ukushintshwa, okunikeza ukonga okuhle kakhulu kwezindleko ngembobo ngayinye.

Ukuhlanganiswa kanye Nekusasa:

Ukuhlanganiswa okuphumelelayo kuhilela ukulawula okunembile kwe-RPM, amazinga okuphakelayo, amandla e-axial, kanye nokupholisa (ngokuvamile ukuqhuma komoya okuncane kune-flood coolant ukuze kugwenywe ukucima i-bushing). Izinhlelo zokuqapha zilandelela ukuguguleka kwamathuluzi kanye nemingcele yenqubo yokulungisa okubikezelayo. Njengoba ukwakheka kwezimoto kuqhubekela phambili ezinhlakeni zezinto eziningi (isb., imizimba ye-aluminium ozimele bensimbi) kanye nokukhanya okukhulu nakakhulu, isidingo sobuchwepheshe be-Flow Drill sizokhula kuphela. Amandla ayo okudala imicu yendawo, eqinile kakhulu ezintweni ezincane, ezihlukahlukene, ngqo ngaphakathi kokugeleza kokukhiqiza okuzenzakalelayo, ibeka i-Thermal Friction Drilling hhayi nje kuphela njengenye indlela, kodwa njengendinganiso yesikhathi esizayo yokubopha izimoto okusebenzayo, okunamandla aphezulu. Kuyinguquko yokwakha buthule izimoto eziqinile, ezilula i-bushing eyodwa ebalulekile ngesikhathi esisodwa.

Isikhathi sokuthunyelwe: Agasti-21-2025