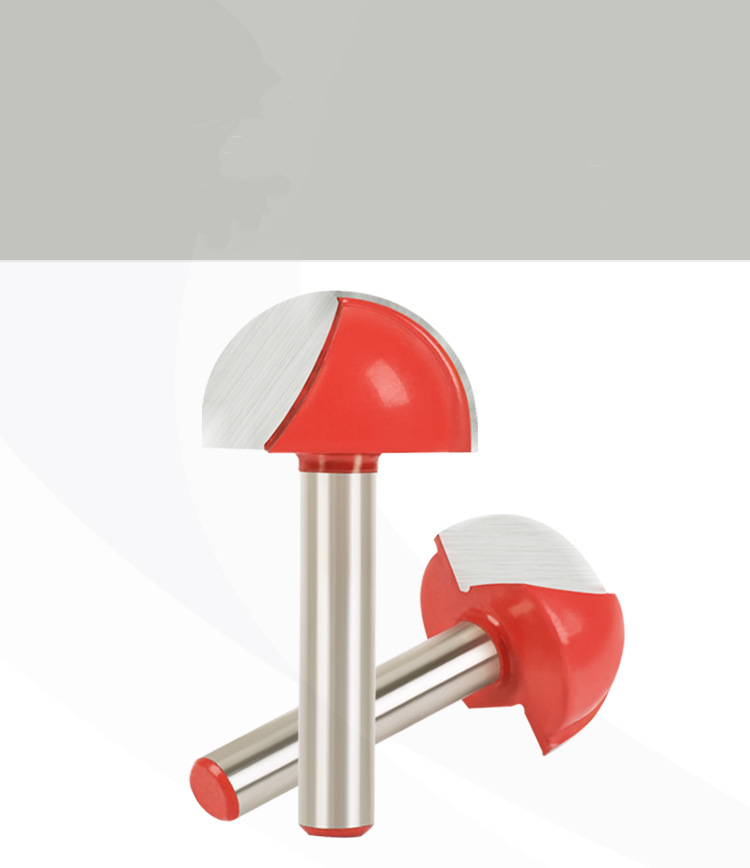

I-Milling Cutter Core Box Router Bit Round Bottom Round Head Umsiki Wokusebenza Ngokhuni

Isici

Inqubo Yokushisela Emvamisa Ephakeme

I-interface igcwele umoya, iqinile futhi akulula ukuyiphula

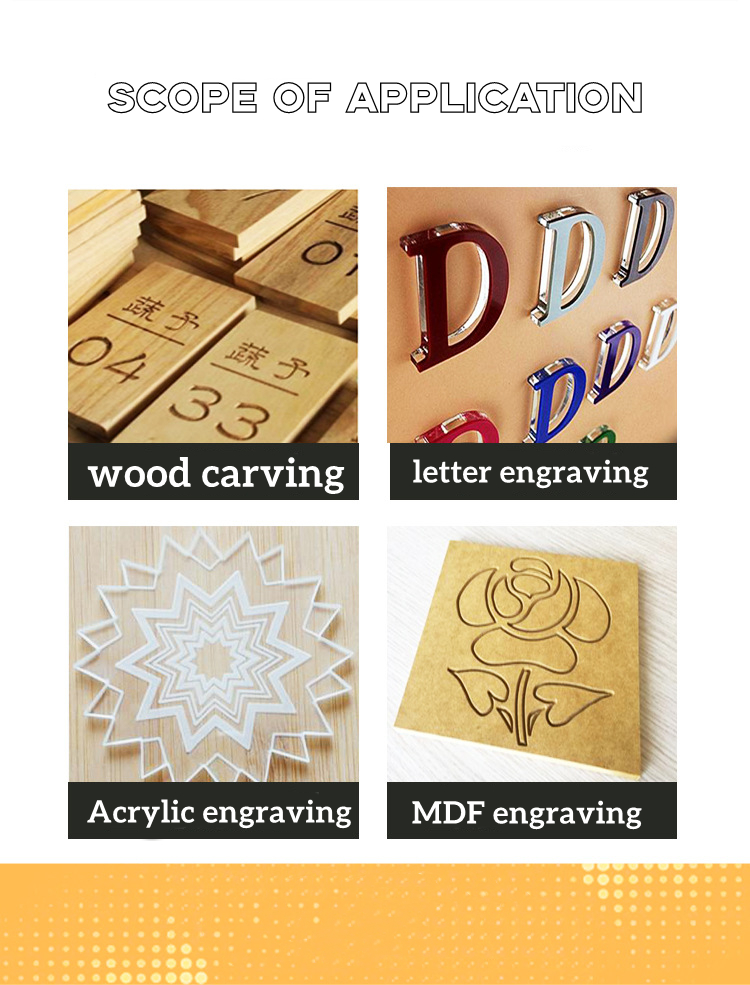

Kufanelekela ukuqoshwa ngokhuni

ukuqoshwa kwezinhlamvu

Ukuqoshwa kwe-Acrylic

Ukuqoshwa kwe-MDF

Ukukhiqizwa kwensimbi ye-tungsten, impilo yesevisi ende, ukwenza ngokwezifiso ukwesekwa

Akukho ma-burrs, ukuphuma okuhle kwama-chip, umphetho wommese obukhali, ukumelana nokuguguleka nokuqina

Ukuqina kwesakhiwo inqubo evuthiwe / enhle futhi eqinile

Ikhwalithi engenziwa ngezifiso ithembekile

Impilo ende, ukuqina okuphezulu/ukusebenza kahle kwezindleko

Isevisi ephelele, isevisi yokusondelana

Insimbi ye-Tungsten

Ukusika nokuqopha izinkuni, i-MDF, njll.

Ububanzi besicelo: imboni yezimoto, izindiza, imboni yesikhunta, imboni ye-IT

Amachashazi aphelele

1. Ukwenza ngokwezifiso uma kudingeka / okungaphezu kwalokho okulindelwe / ikhwalithi ethembekile

2. Izinto ezikhethwayo: Ukuqina kwensimbi ye-tungsten yaseJalimane / ummese obukhali obune

3. Bushelele ngaphandle kwama-burrs

Ubuso bubushelelezi futhi bukhanya, inani lama-chips likhulu, futhi umugqa uyashesha

4. Ukumelana nokuguguleka kanye nokumelana nokugqwala okuphezulu

Akukho ukumelana nokugqwala kanye nokushiswa kwe-oxidation ezindaweni ezinomswakama

Indlela yokusebenzisa ithuluzi lomshini wokuqopha ngokhuni:

1. Kunconywa izigayi zokugaya ezinemigqa eminingi ukuze kusetshenziswe ibhodi lezinhlayiya, njll.

2. Kunconywa ummese wokuqopha idayimane ekuqopheni isibuko se-acrylic.

3. Umphumela wokusetshenziswa kwesikhiphi esingezansi, indawo engaphezulu yomkhiqizo ocutshunguliwe ayinama-burrs, futhi ayikho i-rocker ngesikhathi sokucubungula.

4. Ukuze kucutshungulwe ibhodi elinezingqimba eziningi kanye ne-splint, kunconywa ukusebenzisa i-milling cutter enezinhlangothi ezimbili eqondile.

5. Ukuze uthole ibhodi elinobukhulu obuphezulu kanye nokhuni oluqinile, kunconywa ukusebenzisa umshini wokusika onama-ribbed.

6. Ukuze uthole ukusika okungenama-burr aphezulu naphansi, kunconywa ukusebenzisa umshini wokusika onqenqemeni olulodwa, onqenqemeni oluphindwe kabili kanye nonqenqemeni oluphansi.

7. Ukuze uthole i-cork, i-MDF, ukhuni oluyi-virgin, i-PVC, i-acrylic enkulu, kunconywa ukusebenzisa i-single-edge helical ball end milling cutter.

8. Ukuze kucutshungulwe kahle ukukhululeka okuncane, kunconywa ukusebenzisa umshini wokusika onesisekelo esiyindilinga.

9. Ekusikeni ipuleti le-aluminium, kunconywa ukusebenzisa umshini wokusika we-aluminium okhethekile onezinhlangothi ezimbili. Akunamatheli emmeseni ngesikhathi sokucubungula, isivinini esikhulu kanye nokusebenza kahle okuphezulu.

10. Ekusikeni kwe-MDF, kunconywa ukusebenzisa i-helical milling cutter enezinhlangothi ezimbili enokususwa okukhulu kwe-chip. Inezindawo ezimbili zokususa i-chip ezinomthamo ophezulu kanye nomklamo ozinhlangothi zombili, ongasebenzi nje kuphela ngomsebenzi omuhle wokususa i-chip, kodwa futhi ofinyelela ibhalansi enhle yamathuluzi. Lapho icubungula amabhodi aphakathi nendawo naphezulu, inezici zokungabi mnyama, ukungabi nentuthu ye-cap, kanye nokuphila isikhathi eside kwenkonzo.

11. Ekusikeni kwe-acrylic, kunconywa ukusebenzisa i-single-edged milling cutter, ebonakala ngokucubungula okungenantuthu nokungenaphunga, isivinini esisheshayo, ukusebenza kahle okuphezulu, okungenama-chips anamathelayo, futhi enobungani nemvelo ngempela. Inqubo yayo ekhethekile yokukhiqiza iqinisekisa ukuthi i-acrylic ngeke iqhume. , Iphethini yommese elungile kakhulu (ngisho noma ingenayo iphethini yommese), ubuso bubushelelezi futhi bubushelelezi. Ubuso obufakwe ngomshini budinga ukufeza umphumela weqhwa, futhi kunconywa ukusebenzisa i-spiral milling cutter enezinhlangothi ezintathu ezinhlangothi zombili.