Isixhobo sokusika iTungsten Carbide Dovetail Milling Cutters

Yonke le nto yenziwe ngentsimbi ye-tungsten ekumgangatho ophezulu, enobunzima obuphezulu kunye nokumelana nokuguguleka okuphezulu. Ukusetyenziswa kwezinto zentsimbi ye-alloy esebenza kakuhle, enokumelana okuhle nokushukuma komhlaba. Yenziwe ngeebha zentsimbi ze-tungsten ezintsha ezicoliweyo, ezinokumelana nokuguguleka okuphezulu kunye namandla. Yimela ye-dovetail esemgangathweni ophezulu yokusetyenziswa kobunzima obuphezulu kunye nokusika ngesantya esiphezulu. Ingenza ukucubungula ngesantya esiphezulu kwintsimbi engagqwaliyo, i-aluminium alloy, i-cast iron kunye nezinye izinto ezingaphantsi kwe-HRC55 (kubandakanya i-HRC55). Umatshini, ukunciphisa inani lotshintsho lwezixhobo kunye nokuphucula ukusebenza kakuhle.

Inzuzo:

Ixabiso liphantsi kwaye sikhetha intsimbi ye-tungsten ekumgangatho ophezulu enobunzima obuphezulu kunye nokumelana nokuguguleka okuphezulu

Ukwakha oomatshini ngokuchanekileyo, ukugaywa kakuhle. Ukucubungula ngokuchanekileyo, ukunciphisa ii-burrs ekucutshungulweni kwemveliso-ubuthambile obuphezulu

Ulawulo oluqinileyo lomgangatho, ukuchaneka okuphezulu kunye neemveliso ezigqityiweyo ezibukhali

Uphawu:

1. Ii-engile ezibukhali ziphucula kakhulu ukusebenza kakuhle kokusika

2. Uyilo oluthe tye lwegroove, ukukhupha iitships ezigudileyo ngaphandle kokunamathela kwimela

3. Kuphephe ngokufanelekileyo umoya kwaye wandise ubomi besixhobo

4. Yomeleza ubungqongqo bomphetho osikiweyo, kwaye ibhanti yomphetho we-arc iyahambelana nomphetho osecaleni obukhali kwaye isuse i-burr ngempumelelo.

5. Umjelo wokususa iitshiphusi ezinkulu unciphisa amandla, kwaye ukusika kuthambile ngakumbi, nto leyo efezekisa ukusebenza kakuhle komatshini, kwaye umsebenzi uchaneke ngakumbi kwaye uyamangalisa.

| Uhlobo | Umsiki wokugaya iTungsten Dovetail | Izinto eziphathekayo | Intsimbi yeTungsten |

| Izinto zokusebenzela | Intsimbi engenasici, i-aluminium, intsimbi eyomileyo, isinyithi esityhidiweyo, i-aluminium alloy, intsimbi ye-alloy, i-titanium alloy, njl. | Isixhobo somatshini esisebenzayo | Iziko loomatshini be-CNC, isixhobo somatshini we-CNC, umatshini wokukrola, umatshini wokukrola, umatshini okhawulezayo |

| Iphakheji yoThutho | Ibhokisi | Iflethi | 3/4 |

| Ukwaleka | No | Ukuqina | <=55 |

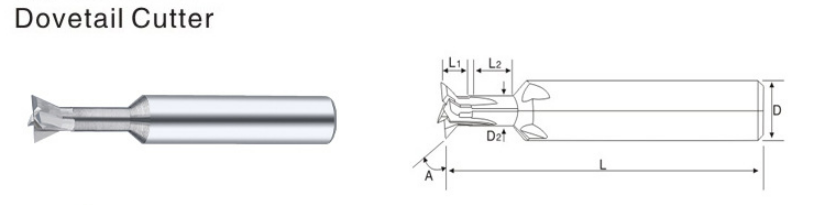

| Ububanzi beFlute(mm) | D2(mm) | L2(mm) | Ukuphakama kweFlute (mm) | Ububanzi be-Shank(mm) | Ubude obupheleleyo (mm) | Iifluti |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 | 20 | 75 | 4 |

Sebenzisa:

Isetyenziswa kakhulu kwiindawo ezininzi

Ukuveliswa kweenqwelo moya

Imveliso yoomatshini

Umenzi weemoto

Ukwenza isikhunta

Ukuveliswa koMbane

Ukucubungula nge-lathe