Impumelelo yokuvelisa egxile kwiibhithi ezintsha zokubhola amanzi (ezaziwa ngokubai-thermal friction drill bits okanye i-flowdrill) iguqula indlela amashishini enza ngayo imisonto eqinileyo nethembekileyo kwisinyithi esincinci kunye neetyhubhu. Le teknoloji isekelwe ekungqubaneni isusa isidingo sokubhola kunye nokucofa kwendabuko, inika inzuzo enkulu kumandla, isantya, kunye nokusebenza kakuhle kweendleko, ngakumbi kwicandelo leemoto, i-aerospace, kunye ne-elektroniki.

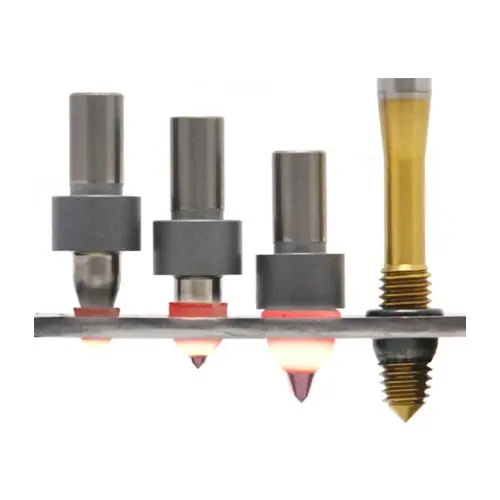

Uyilo oluphambili lukwinkqubo eyahlukileyo eqhutywa zezi zixhobo zikhethekileyo. Ngokungafaniyo needrill eziqhelekileyo ezisika kwaye zisuse izinto, i-flow drill bit ivelisa ubushushu obukhulu ngokudityaniswa kwesantya esiphezulu kakhulu sokujikeleza kunye noxinzelelo olulawulwayo lwe-axial. Njengoko incam ye-tungsten carbide eyenziwe ngokukodwa idibana nomphezulu wezinto zokusebenza, ukungqubana kuyayifudumeza ngokukhawuleza isinyithi esingaphantsi - ngesiqhelo isinyithi, isinyithi esingenasici, i-aluminium, okanye i-alloys yobhedu - ukuya kwimeko yayo yeplastiki (malunga ne-600-900°C kuxhomekeke kwizinto).

Olu hlobo lwe-bushing olubunjiweyo luphawu olubalulekileyo. Ngokwesiqhelo lufikelela kubukhulu obuphindwe kathathu kunobo besiseko. Umzekelo, ukufaka intambo kwiphepha elinobukhulu obuyi-2mm kwenza ikhola eqinileyo enobude obuyi-6mm. Oku kwandisa kakhulu ubunzulu bokudityaniswa kwentambo ngaphaya koko bekunokwenzeka ngobukhulu bezinto eziluhlaza zodwa.

Emva kokwenziwa kwe-bushing, inkqubo idla ngokuqhubeka ngaphandle kokuphazamiseka. I-tep eqhelekileyo ilandela i-iqhekeza lokubhola amanzi, nokuba kwangoko kumjikelo ofanayo womatshini (kwizixhobo ezihambelanayo) okanye kumsebenzi olandelayo. Impompi inqumla imisonto echanekileyo ngqo kwi-bushing entsha eyenziweyo, enodonga oluqinileyo. Ekubeni i-bushing iyinxalenye yesakhiwo sokuqala se-grain yezinto, kungekhona into eyongeziweyo, imisonto evelayo inamandla aphezulu kakhulu kwaye ilungile.

Iingenelo eziphambili zokuqhuba ukwamkelwa:

Amandla Angenakuthelekiswa Kwizinto Ezincinci: I-bushing ye-3x inika ukubandakanyeka okuphezulu kakhulu kwentambo xa kuthelekiswa nokucofa ubukhulu besiseko ngokuthe ngqo okanye ngokusebenzisa i-inserts.

Isantya kunye nokusebenza kakuhle: Idibanisa ukwenza imingxunya kunye nokwakheka kwe-bushing ibe ngumsebenzi omnye okhawulezayo (ngemizuzwana emininzi ngomngxuma ngamnye), isusa amanyathelo okubhoboza ahlukeneyo, ukususa iibhombu, kunye nokufaka.

Ukonga Izinto Ezisetyenzisiweyo: Akukho zitshiphusi ziveliswayo ngexesha lesigaba sokugrumba amanzi, nto leyo enciphisa inkunkuma yezinto ezisetyenzisiweyo.

Iijoyinti Ezivaliweyo: Izinto ezisusiweyo zihamba kakuhle zijikeleze umngxuma, nto leyo edla ngokwenza ijoyinti engavuziyo ilungele ukusetyenziswa kolwelo okanye uxinzelelo.

Izixhobo Ezincitshisiweyo: Ziphelisa isidingo samandongomane, amandongomane e-weld, okanye izinto ezifakwe i-riveted, nto leyo eyenza kube lula ii-BOM kunye ne-logistics.

Inkqubo yokuCoca: Iitships ezincinci kwaye akukho mfuneko yokusika ulwelo kwiindawo ezininzi (ukuthambisa ngamanye amaxesha kusetyenziswa ixesha elide okanye izinto ezithile).

Ukusetyenziswa Kuninzi: Le teknoloji ikhula ngokukhawuleza naphi na apho izinto ezikhaphukhaphu ezincinci zifuna uqhagamshelo oluqinileyo olunemisonto:

Iimoto: Iitreyi zebhetri zesithuthi sombane, izinto zetshasi, izibiyeli, iinkqubo zokukhupha umoya, izakhelo zesihlalo.

I-Aerospace: Iiphaneli zangaphakathi, ii-ducting, iibrakethi zesakhiwo ezikhaphukhaphu.

Izixhobo ze-elektroniki: Iirakhi zeseva, iiphaneli ezibiyelweyo, izinki zobushushu.

I-HVAC: Iintambo zokuxhuma isinyithi, izibiyeli.

Ifenitshala kunye nezixhobo: Iifreyimu zesakhiwo ezifuna iindawo zokubopha ezifihlakeleyo neziqinileyo.

Abavelisi bee-flow drill bits bayaqhubeka nokuphucula ijometri, ii-coating, kunye nezinto ezidityanisiweyo ukuze bandise ubomi bezixhobo, baphucule ukusebenza kwii-alloys eziphambili, kwaye baphucule inkqubo yokwenza izinto ngokuzenzekelayo. Njengoko amashishini eqhubeka nokulandela ukukhanya nokusebenza kakuhle kwemveliso, ukubhola ngoxinzelelo lobushushu, okuqhutywa yinkqubo entsha.i-flowdrillbit, ibonakalisa ukuba sisisombululo esibalulekileyo ekudaleni imisonto esebenza kakuhle apho yayikade ingenakwenzeka okanye ingasebenzi. Ixesha lokulwa nemisonto ebuthathaka kwiishiti ezincinci linika indawo yamandla kunye nobulula beebhuthi ezenziwe ngokungqubana.

Ixesha leposi: Julayi-30-2025