Kwishishini lemveliso elihlala litshintsha, ukufuna ukusebenza kakuhle, ukuchaneka kunye nokuvelisa izinto ezintsha akupheli. Enye yezona teknoloji zintsha ezivele kwiminyaka yakutshanje kukugrumba okuhambayo, ingakumbi xa kudityaniswe nokugrumba okushushu. Le ndlela ayiphuculi nje kuphela umgangatho wemveliso yokugqibela kodwa ikwayenza lula inkqubo yokuvelisa, nto leyo eyenza kube yinto etshintsha umdlalo kumashishini aqala kwiimoto ukuya kwinqwelomoya.

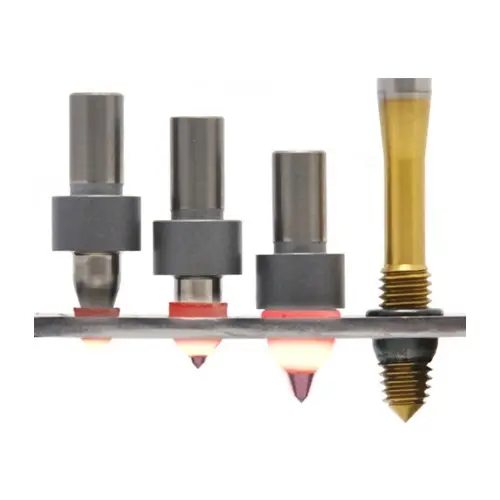

Ukubhola umbhobhoUkuyila yinkqubo eyahlukileyo esebenzisa ukujikeleza okukhawulezayo kunye noxinzelelo lwe-axial ukwenza iplastiki yezinto ezigrunjwayo. Eli nyathelo lokuqala libaluleke kakhulu kuba liguqula izinto eziluhlaza zibe yimeko enokugutyungelwa, livumela iimilo kunye neempawu ezintsonkothileyo ukuba zenziwe ngaphandle kweendlela zemveli zokugaya. Isiphumo? I-bushing ebunjiweyo ephindwe kathathu kunezinto eziluhlaza. Obu bukhulu bongeziweyo abugcini nje ngokuphucula ukuthembeka kwesakhiwo secandelo, kodwa bukwabonelela ngesiseko esiqinileyo sokuqhubekeka nokucutshungulwa.

Inyathelo lesibini kwinkqubo yokubhoboza ukuhamba kwamanzi kukwenza imisonto ngokusebenzisa i-extrusion ebandayo. Le teknoloji iluncedo kakhulu kuba inokuvelisa imisonto echanekileyo, ene-torque ephezulu kunye ne-specification ephezulu efunekayo kwiintlobo ngeentlobo zezicelo. Inkqubo ye-extrusion ebandayo inciphisa inkunkuma yezinto kwaye iqinisekisa ukuba imisonto yenziwe ngocoselelo olukhulu, nto leyo ibaluleke kakhulu kushishino apho nokuba kuthe tye kancinci kunokukhokelela ekungaphumelelini okukhulu.

Enye yezona zinto zibalaseleyo kwiibhithi zokubhola ezishushu ezisetyenziswa kunye needrili zokugeleza kukwazi kwazo ukuvelisa ubushushu ngokubhoxa. Olu bushushu lunceda ngakumbi ekwenzeni izinto zibe plastiki, nto leyo evumela ukubhola okuthambileyo kunye nokunciphisa ukuguguleka kwebhithi yokubhola ngokwayo. Ngenxa yoko, abavelisi banokufikelela kwixesha elide lokusebenza kwezixhobo kunye nexesha elincinci lokungasebenzi, ekugqibeleni bandise imveliso kwaye bonge iindleko.

Ukongeza, ukudityaniswa kwe-flow drill kunye ne-thermal friction drill kuvula amathuba amatsha ekukhetheni izinto. Abavelisi ngoku banokusebenza ngoluhlu olubanzi lwezixhobo, kuquka nezinto ezazithathwa njengezinzima ukugrumba okanye ukuzibumba ngaphambili. Olu tshintsho alupheleli nje ekwandiseni ukusetyenziswa okunokwenzeka kwe-flow drill, kodwa lukwavumela uphuhliso lweemveliso ezintsha ezihlangabezana neemfuno zabathengi banamhlanje.

Ukongeza kwiingenelo zobugcisa, impembelelo yokwemba ngokugeleza komoya ayinakutyeshelwa kwindalo esingqongileyo. Iindlela zokugrumba zemveli zihlala zivelisa inkunkuma eninzi kwaye zifuna ukusetyenziswa kwamandla amaninzi. Ngokwahlukileyo koko, ukugrumba ngokugeleza komoya kusetyenziswai-thermal friction drill bits lukhetho oluzinzileyo ngakumbi kuba lunciphisa inkunkuma kwaye luphucula ukusetyenziswa kwamandla. Oku kuhambelana nomkhwa okhulayo weendlela zokwenza izinto ezinobuhlobo nokusingqongileyo, nto leyo eyenza ukuba ibe lukhetho olufanelekileyo kwiinkampani ezifuna ukuqinisa imizamo yazo yokuzinza.

Njengoko amashishini eqhubeka nokufuna iindlela zokwandisa ukusebenza kakuhle nokunciphisa iindleko, ukusetyenziswa kokugrumba okuhambayo ngee-thermal friction drills kusenokwenzeka ukuba kunyuke. Le ndlela intsha ayizukuphucula kuphela umgangatho wemveliso yokugqibela, kodwa ikwayenza lula inkqubo yokuvelisa, nto leyo eyenza kube yimpumelelo kubavelisi nakubathengi.

Ngamafutshane, indibaniselwano yokubhola ngokugeleza kwamanzi kunye needrili zokungqubana kobushushu imele inkqubela phambili ebalulekileyo kubuchwepheshe bokuvelisa. Ngokufaka izinto kwiplastiki ngokujikeleza ngesantya esiphezulu kunye noxinzelelo lwe-axial, kunye nokwenza imisonto echanekileyo kakhulu ngokusebenzisa i-extrusion ebandayo, le ndlela inika iingenelo ezingenakuthelekiswa nanto ekusebenzeni kakuhle, ngokuchanekileyo kunye nokuzinza. Njengoko siqhubeka phambili, kuya kuba mnandi ukubona indlela obu buchwepheshe obuqhubeka ngayo nokuphuhlisa nokubumba ikamva lokuvelisa.

Ixesha lokuthumela: Jan-09-2025