Kwihlabathi elikhawulezayo lokwenziwa kwezinto ze-elektroniki, apho ukuchaneka kwe-micron-level kuchazwa khona impumelelo, ukwaziswa kwe-Next-Gen PCB Board Drill Bits kubonisa inqanaba eliphezulu ekwenzeni iibhodi zesekethe. Zenzelwe ukubhola, ukukrola, kunye nokwenza i-micromachining kwiibhodi zesekethe eziprintiweyo (ii-PCB) kunye nezinye izinto ezincinci kakhulu, ezi Tungsten SteelI-Mini Drill PCBIzixhobo zidibanisa izixhobo zenqwelo-moya kunye netekhnoloji yozinzo lwenyikima ukuze kuchazwe kwakhona ukusebenza kakuhle kunye nobude bexesha kwimveliso enomthamo omkhulu.

Ubuchule Bobunjineli: Kutheni Intsimbi yeTungsten Ibalulekile

Embindini wezi drill bits kukho i-tungsten carbide (WC) ecocekileyo kakhulu, into ekhethiweyo ngenxa yomxube wayo ongenakuthelekiswa nanto wobunzima (HRA 92), ukumelana nokuguguleka, kunye nokuqina kwesakhiwo. Ngokungafaniyo needrill ze-HSS (High-Speed Steel) eziqhelekileyo, le fomyula yentsimbi ye-tungsten inika:

Ixesha elide eli-3X: Imelana nemijikelo yokubhola engaphezu kwe-15,000 kwiibhodi ze-fiberglass ze-FR-4 ngaphandle kokuwohloka komphetho.

Ulwakhiwo lweMicro-Grain: Iigrains zecarbide ezingaphantsi kwe-0.5µm ziqinisekisa imiphetho yokusika ebukhali njengerazor, zifikelela kububanzi bemingxuma obuncinci njenge-0.1mm kunye nokunyamezelana kwe-±0.005mm.

Uyilo Oluchasene Nokwaphuka: I-geometry ye-shank eqinisiweyo ithintela ukwaphuka ngexesha lemisebenzi ye-RPM ephezulu (30,000–60,000), nokuba kwizixhobo ze-PCB ezizaliswe yi-ceramic ezibuthathaka.

Uvavanyo lweqela lesithathu oluqhutywa yiPrecision Machining Institute of Technology luqinisekisa ukuba ezi bits zigcina ukugqitywa komphezulu weRa 0.8µm emva kwemingxuma eyi-10,000 - into ebalulekileyo ekuqinisekiseni ukuthembeka kwesignali kwizixhobo ze-5G kunye ne-IoT.

Uzinzo lweSeismic: Ukusika Ngaphandle Kokuyekelela

Ukubhola nge-PCB kufuna uzinzo olupheleleyo ukuze kuthintelwe "ukuhamba" okanye ukungalungelelani kwemingxunya. Uyilo lwe-Proprietary Seismic Blade Edge lujongana noku ngale ndlela:

I-Flute Geometry engalinganiyo: Ilungelelanisa ukukhutshwa kweetshiphusi kunye nokuxinana kokungcangcazela, inciphisa amandla asecaleni ngama-40%.

I-Nano-Coated Helix Angle: I-30° helix ene-TiAlN coating inciphisa ukwakheka kobushushu (<70°C) ngexesha lokusebenza okuqhubekayo.

Ii-Anti-Resonance Grooves: Ii-micro-channels ezifakwe nge-laser ziphazamisa amaza e-harmonic, ziqinisekisa ukuchaneka kwendawo ngaphakathi kwe-5µm kwii-PCB ezineeleya ezili-10.

Kuvavanyo loxinzelelo lokubhoboza imingxunya ye-0.3mm kwiibhodi ezigqunywe nge-aluminium eziyi-2mm, ezi bhithi azibonisanga ukuphambuka kwimijikelo engama-500 elandelelanayo – into engenakuthelekiswa nanto phakathi kwabakhuphisana nabo.

Izicelo Kuwo Wonke Amashishini

Izixhobo ze-elektroniki zabathengi

Kwabavelisi bebhodi yomama yefowuni:

Ii-Micro-Vias ze-0.2mm: Zifikelele kwizinga le-99.9% leemveliso kwiibhodi ze-HDI ezineeleya ezili-12.

Amaxabiso okutya akhawulezayo angama-20%: Asebenza ngokunciphisa ukungqubana kunye nokuvaleka kweetship.

Izixhobo zombane zeemoto

Kwimveliso yemodyuli yamandla e-EV:

Ukuthembeka kweMingxunya Engena kwiMingxunya: Kugcinwe umbane oqhubekekayo nge-100% kwiindawo ezisebenzisa ubushushu ezizi-1.6mm ubukhulu.

Ukusebenza Okungenasipholisi: Ukugrumba okomileyo kuthintela ungcoliseko kwiinkqubo zolawulo lwebhetri ezivaliweyo.

Inqwelo-moya kunye noKhuselo

Ukubhoboza imingxunya eyi-0.15mm kwiisekethe ze-polyimide flex:

Akukho Kuqhekeka: Nokuba kwindawo enomswakama ophezulu ngama-200°C.

Umzobo weShield ye-EMI: Ukukrola ngokuchanekileyo kwi-RF shielding layers ezisekelwe kwi-graphene.

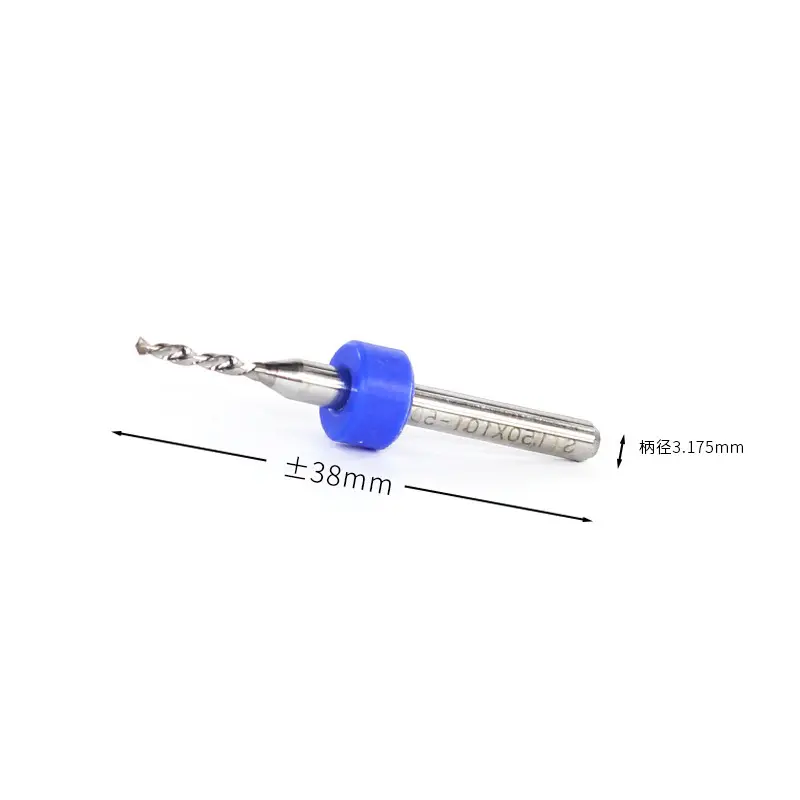

Iinkcukacha zobugcisa

Uluhlu lobubanzi: 0.1mm–3.175mm (0.004"–1/8")

Uhlobo lweShank: Umgangatho oqhelekileyo we-3.175mm (1/8") okanye ukuhambelana kwe-collet ye-ER ngokwezifiso

Iinketho zokugquma: I-TiN (igolide), i-TiCN (eluhlaza okwesibhakabhaka), okanye i-Diamond-Like Carbon (DLC)

I-RPM ephezulu: 80,000 (kuxhomekeke kububanzi)

Ukuhambelana: Oomatshini bokugrumba be-CNC, oomatshini bokugrumba be-PCB abazenzekelayo, izixhobo ezijikelezayo eziphathwayo

Ukusebenza kakuhle kweendleko kuchazwe ngokutsha

Uhlalutyo lweendleko kunye neenzuzo olwenziwe ngumenzi we-PCB ophambili waseTaiwan lutyhile:

Izaphulelo zonyaka ze-$18,500: Ukutshintshwa kwee-drill bit ezincitshisiweyo (ukusuka kwiiseti ezili-12 ukuya kwezi-4 ngonyaka).

Ukuncitshiswa kwamandla yi-15%: Iimfuno eziphantsi ze-spindle torque.

Akukho Kuphinda Kusetyenziswe: Kususwe i-$220k ngonyaka kwiibhodi ezilahliweyo kwi-drill wander.

Uzinzo Olwakhelwe Ngaphakathi

Ukupakisha Okungasetyenziswa kwakhona: Iitreyi zefoam ezibolayo eziyi-100%.

Ukuthobela iRoHS kunye neREACH: Akukho lead, i-cadmium, kunye nezinye izinto eziyingozi.

Ubomi beZixhobo eziNcitshisiweyo: Ukusetyenziswa kwe-tungsten okuphantsi ngama-60% xa kuthelekiswa nokuqheliswa okuqhelekileyo.

Ubungqina boMsebenzisi

"Ukutshintshela kwezi ntsimbi ze-tungsten kube yinguqu," utshilo uHiroshi Tanaka, uMphathi weMveliso kumvelisi we-sensor oseKyoto. "Sigrumba imingxunya engama-20,000 ngokutshintsha ngakunye ngaphandle kokutshintsha kwezixhobo - into engenakucingelwa ngee-HSS drills zethu ezindala. Uyilo lwe-seismic lodwa lunciphisa ukugatywa kwethu kwendawo yemingxunya ngama-95%.

Kutheni Ukhetha Ezi PCB Board Drill Bits?

Ukuchaneka Okungaphukiyo: Ukuze kubekho ukuchaneka okufana nelaser kwiibhodi ze-high-density interconnect (HDI).

Isantya Esingenamsebenzi: Bhoboza imingxuma eyi-0.3mm kwimingxuma engama-400 ngomzuzu ngaphandle kokuphazamisa umgangatho womphetho.

Ukuhambelana kwe-Universal: Isebenza ne-FR-4, i-Rogers, i-aluminium, kwanee-laminates eziqiniswe ngeglasi.

Uyilo Olungqina Ikamva: Lulungele izixhobo ze-PCB zesizukulwana esilandelayo ezifana nee-dielectric ezingenayo i-halogen kunye nee-dielectric ezilahleka kancinci kakhulu.

Isiphelo

Kwishishini apho yonke i-micron ilawula inzuzo kunye nokusebenza, ezi Tungsten SteelIibhithi zokubhola zeBhodi yePCBazikho nje izixhobo – ziluncedo kakhulu. Ngokudibanisa isayensi yezinto eziphathekayo kunye nobunjineli bozinzo, zinika amandla abavelisi ukuba badlule kwimida ye-miniaturization ngelixa benciphisa

Ixesha leposi: Matshi-21-2025