Kwimizi-mveliso eqala kwimveliso yeemoto ukuya ekuhlanganiseni izixhobo ze-elektroniki, umngeni wokudala imisonto eqinileyo neyomeleleyo kwizinto ezincinci usoloko ukhathaza iinjineli. Iindlela zokubhola kunye nokuthepha zendabuko zihlala ziphazamisa ukuthembeka kwesakhiwo okanye zifuna ukuqinisa okubiza kakhulu. Ngena kwi-I-Flowdrill M6 – isisombululo sokugrumba esiphucukileyo esisebenzisa ubushushu, uxinzelelo, kunye nobunjineli bokuchaneka ukuvelisa imisonto eqinileyo kwizinto ezincinci njenge-1mm, ngaphandle kokugrumba kwangaphambili okanye ezinye izinto ezongezelelweyo.

Isayensi Engasemva kweFlowdrill M6

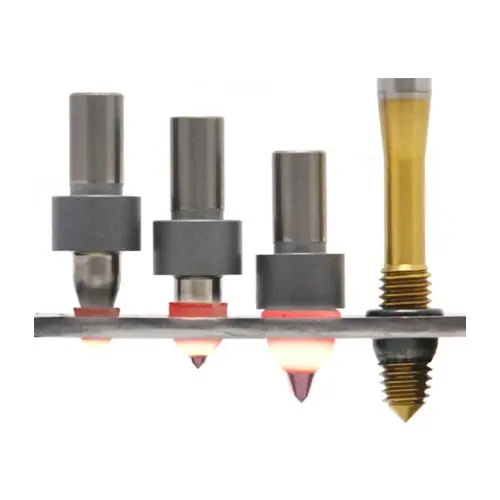

Embindini wayo, i-Flowdrill M6 isebenzisa ukubhola kwe-thermomechanical friction, inkqubo edibanisa ukujikeleza ngesantya esiphezulu (15,000–25,000 RPM) kunye noxinzelelo lwe-axial olulawulwayo (200–500N). Nantsi indlela eguqula ngayo amaphepha amancinci abe yimisebenzi yobugcisa enemisonto:

Ukuveliswa kobushushu: Njengoko i-drill ene-carbide-tip idibana ne-workpiece, ukungqubana kunyusa amaqondo obushushu aye kuma-600–800°C kwimizuzwana embalwa, oku kuthambisa izinto ngaphandle kokuzinyibilikisa.

Ukususwa kwezinto: Intloko ye-drill ekhonkrithi iyenza iplastiki kwaye ithathe indawo yesinyithi, yenze i-bushing ephindwe kathathu kunobukhulu bokuqala (umz., ukuguqula iphepha le-1mm libe yi-boss enemisonto ye-3mm).

Ukudityaniswa kweMisonto: Itephu eyakhelwe ngaphakathi (umgangatho we-M6×1.0) ikhawuleza ibanda-iyenze imisonto echanekileyo ehambelana ne-ISO 68-1 kwikhola entsha etyebileyo.

Lo msebenzi wenyathelo elinye ususa iinkqubo ezininzi - akukho mfuneko yokubhoboza, ukuxovula, okanye ukucofa ngokwahlukeneyo.

Iingenelo eziphambili kuneendlela eziqhelekileyo

1. Amandla Omsonto Angalinganiyo

Ukuqinisa Izinto ezingama-300%: Ubunzulu bokudityaniswa kwentambo nge-bushing ekhutshiweyo bubonisa ubunzulu bokudityaniswa kwentambo.

Ukuqina Komsebenzi: Ukulungiswa kweenkozo okubangelwa kukungqubana kwandisa ubulukhuni beVickers ngama-25% kwindawo enemisonto.

Ukumelana nokutsalwa: Uvavanyo lubonisa umthamo womthwalo we-axial ophezulu nge-2.8x xa kuthelekiswa nemisonto esikiweyo kwi-aluminium eyi-2mm (1,450N xa kuthelekiswa ne-520N).

2. Ukuchaneka Ngaphandle Kokuyekelela

±0.05mm Ukuchaneka kweNdawo: Iinkqubo zokutya ezikhokelwa yiLaser ziqinisekisa ukuchaneka kokubekwa kwemingxunya.

Ukugqitywa komphezulu weRa 1.6µm: Ithambile kunemisonto egayiweyo, inciphisa ukuguguleka kwezixhobo zokubopha.

Umgangatho Ohlala Uhleli: Ulawulo lobushushu/uxinzelelo oluzenzekelayo lugcina ukunyamezelana kwimijikelo engaphezu kwe-10,000.

3. Ukonga iindleko kunye nexesha

Amaxesha Omjikelo Okhawulezayo angama-80%: Dibanisa ukubhoboza kunye nokufaka imisonto kumsebenzi omnye wemizuzwana emi-3-8.

Ulawulo lwe-Zero Chip: Ukugrumba iifriction akuvelisi ngxaki, kulungele iindawo ezicocekileyo kwigumbi.

Ixesha Elide Lesixhobo: Ukwakhiwa kwekhabhayithi yeTungsten kumelana nemingxunya engama-50,000 yentsimbi engagqwaliyo.

Izicelo Eziqinisekisiweyo Kushishino

Ubunzima beeMoto

Umenzi ohamba phambili we-EV wasebenzisa i-Flowdrill M6 kwiindibano zetreyi yebhetri:

I-Aluminiyam eyi-1.5mm → I-4.5mm Threaded Boss: Izibophelelo ze-M6 ezivunyiweyo zikhusela iipakethe zebhetri ezingama-300kg.

Ukunciphisa Ubunzima ngama-65%: Amantongomane atshisiweyo kunye neepleyiti ezingasemva ezisusiweyo.

I-40% yeendleko zokonga: Ixabiso eliphantsi le-$2.18 ngecandelo ngalinye kwiindleko zomsebenzi/zezinto zokwakha.

Imigca yeHydraulic yeAerospace

Kwimibhobho yolwelo lwe-titanium eyi-0.8mm:

IiSeal zeHermetic: Ukuhamba kwezinto rhoqo kuthintela iindlela zokuvuza ezincinci.

Ukumelana nokungcangcazela: Uvavanyo lokudinwa olusinde kwi-10⁷ cycle kwi-500Hz lusindile.

Izixhobo ze-elektroniki zabathengi

Kwimveliso yetshasi yeefowuni eziphathwayo:

Izithintelo ezifakwe imisonto kwi-1.2mm Magnesium: Izixhobo ezincinci ezivulwe ngaphandle kokuphazamisa ukuxhathisa kokuwa.

Ukukhusela i-EMI: Ukuqhuba kwezinto okungaphazamisekiyo kwiindawo zokubopha.

Iinkcukacha zobugcisa

Ubungakanani boMsonto: M6×1.0 (I-M5–M8 eyenzelwe wena iyafumaneka)

Ukuhambelana kwezinto: I-Aluminiyam (uthotho lwe-1000–7000), Intsimbi (ukuya kuthi ga kwi-HRC 45), iTitanium, iiCopper Alloys

Ubukhulu bephepha: 0.5–4.0mm (Uluhlu olufanelekileyo yi-1.0–3.0mm)

Iimfuno zamandla: I-2.2kW spindle motor, i-coolant ye-6-bar

Ubomi beSixhobo: 30,000–70,000 imingxunya kuxhomekeke kwizinto ezisetyenzisiweyo

Umda woZinzo

Ukusebenza kakuhle kwezinto: Ukusetyenziswa ngokupheleleyo - isinyithi esisusiweyo siba yinxalenye yemveliso.

Ukonga Amandla: Ukusetyenziswa kwamandla okuphantsi ngama-60% xa kuthelekiswa nokubhola + ukucofa + iinkqubo zokuwelda.

Ukusebenziseka kwakhona: Akukho zinto zifanayo (umz., izinto zokufakelwa zethusi) eziza kwahlulwa ngexesha lokurisayikilisha.

Isiphelo

I-Flowdrill M6 ayisosixhobo nje kuphela – lutshintsho oluqhelekileyo kwindlela yokwenza izinto ezincinci. Ngokuguqula ubuthathaka besakhiwo bube zizinto eziqinisiweyo, inika amandla abayili ukuba baqhubele phambili ukukhanyisa ngelixa begcina imigangatho yokusebenza eqinileyo. Kumashishini apho igram nganye kunye ne-micron nganye zibalulekile, obu buchwephesha buvala umsantsa phakathi kobuncinci kunye nokuqina.

Ixesha lokuthumela: Matshi-20-2025