Ukuqhubela phambili okungapheliyo kwizithuthi ezikhaphukhaphu, ezinamandla, nezisebenza kakuhle, ngakumbi ngokukhula okukhulu kweZithuthi zoMbane (ii-EV), kubeka uxinzelelo olukhulu kwimveliso yeemoto. Iindlela zemveli zokwenza uqhagamshelo oluqinileyo olunemisonto kwisinyithi esincinci - into ephambili kwimizimba yemoto yanamhlanje, iifreyimu, kunye nezivalo - zihlala ziquka izibophelelo ezongeziweyo ezifana neenkuni ze-weld okanye iinkuni ze-rivet. Ezi zizisa ubunzima, ubunzima, iindawo zokusilela, kunye namaxesha okujikeleza acothayo. Ngena kwi-Thermal Friction Drilling (TFD) kunye nezixhobo zayo ezikhethekileyo -I-Carbide Flow Drill Bits kunye neeThermal Friction Drill Bit Sets – itekhnoloji eguqula ngokukhawuleza imigca yemveliso yeemoto ngokuzenzekela ukudalwa kwemisonto edibeneyo, enamandla aphezulu ngqo ngaphakathi kwezinto ezincinci.

Umngeni Wokubopha Iimoto: Ubunzima, Amandla, Isantya

Iinjineli zeemoto zihlala zilwa nobunzima obufanayo. Iintsimbi ezincinci nezinamandla aphezulu kunye nee-aluminium alloys zibalulekile ekunciphiseni ubunzima bezithuthi kunye nokuphucula ukusebenza kakuhle kwepetroli okanye uluhlu lwe-EV. Nangona kunjalo, ukudala imisonto ethembekileyo ethwala umthwalo kwezi nxalenye zincinci kuyingxaki:

Ukubandakanyeka Okulinganiselweyo: Ukucofa okuqhelekileyo kwiphepha elincinci kunika ukubandakanyeka okuncinci kwimisonto, nto leyo ekhokelela ekubeni ingatsalwa ngamandla kwaye ithambeke lula.

Ubunzima Obongezelelweyo kunye Nobunzima: Ukuwelda amantongomane, amantongomane e-clinch, okanye amantongomane e-rivet kongeza iindawo, kufuna imisebenzi yesibini (ukuwelda, ukucinezela), ukwandisa ubunzima, kunye nokwazisa iindawo ezinokubakho zokugqwala okanye imiba yokulawula umgangatho.

Iingxaki zeNkqubo: Ukubhoboza okwahlukileyo, ukufakwa/ukufakelwa kwezincamathelisi, kunye namanyathelo okucofa acothisa imigca yemveliso ephezulu.

Ubushushu kunye nokuphambuka: Iinati zokuwelda zivelisa ubushushu obukhulu, ezinokujika iipaneli ezincinci okanye zichaphazele iimpawu zezinto ezikwindawo echaphazelekileyo kubushushu (HAZ).

Ukubhola Kombhobhos: Isisombululo Esizenzekelayo Esikwi-Line

Ukubhola i-Thermal Friction, okudityaniswe kwiindawo zoomatshini be-CNC, ii-robotic cells, okanye oomatshini abazinikeleyo be-multi-spindle, kunika impendulo echukumisayo:

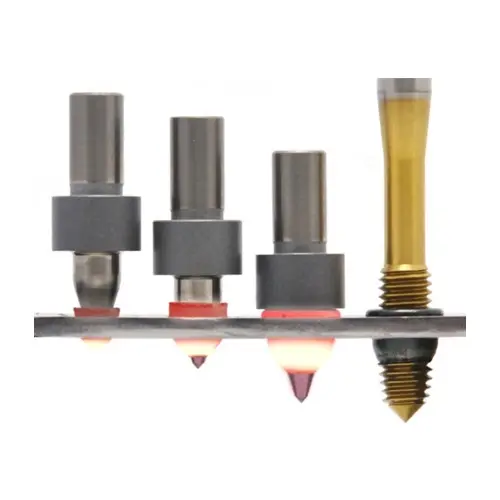

I-Powerhouse Yokusebenza Komnye: Umlingo oyintloko we-TFD ulele ekudibaniseni ukubhola, ukwakheka kwe-bushing, kunye nokucofa kwi-operation enye engenamthungo, ezenzekelayo. I-Carbide Flow Drill Bit enye, ejikeleza ngesantya esiphezulu (ngesiqhelo i-3000-6000 RPM yentsimbi, ephezulu kwi-aluminium) phantsi kwamandla amakhulu e-axial, ivelisa ubushushu obukhulu bokungqubana. Oku kwenza isinyithi sibe yiplastiki, sivumele i-geometry eyahlukileyo ye-bit ukuba ihambe kwaye isuse izinto, yenze i-bushing engenamthungo, edibeneyo malunga nobukhulu obuphindwe kathathu bephepha lokuqala.

Ukucofa Kwangoko: Njengoko iFlow Drill irhoxa, kulandela itephu eqhelekileyo (edla ngokuba kwisixhobo esinye esikwinkqubo yokutshintshiselana ngokuzenzekelayo okanye i-synchronous second spindle) ngoko nangoko, isika imisonto echanekileyo kakhulu kule bushing intsha, enodonga oluqinileyo. Oku kuphelisa ukuphathwa phakathi kwemisebenzi kwaye kunciphisa kakhulu ixesha lokujikeleza.

Ukuhlanganiswa kweRobhothi: Iiseti zeBit Drill Bit zeThermal Friction zifanelekile kwiingalo zerobhothi. Amandla azo okwenza yonke inkqubo yokudala intambo ngendlela enye yesixhobo (ukubhola phantsi, ukwenza i-bushing, ukurhoxa, ukucofa phantsi, ukurhoxa) kwenza kube lula ukuprograma kunye nokusebenza kwerobhothi. Iirobhothi zinokubeka ngokuchanekileyo isixhobo phezu kwee-contours ezintsonkothileyo kwizakhiwo zomzimba ezimhlophe (BIW) okanye ii-sub-assembly.

Kutheni Abavelisi beeMoto besebenzisa iiFlow Drills:

Amandla Omsonto Anyuswe Kakhulu: Le yeyona nzuzo iphambili. Imisonto ibandakanya i-bushing etyebileyo (umz., ukwenza i-bushing ende eyi-9mm ukusuka kwiphepha le-3mm), nto leyo ebangela ukuba amandla okutsalwa nokuhlutywa aqhele ukugqitha lawo e-weld nuts okanye i-rivet nuts. Oku kubalulekile kwiindawo ezibalulekileyo kukhuseleko (ii-ankile zebhanti yesihlalo, ii-suspension mounts) kunye neendawo ezinokungcangcazela kakhulu.

Ukunciphisa Ubunzima Okubalulekileyo: Ukususa i-weld nut, i-rivet nut, okanye i-clinch nut ngokwayo kususa ubunzima. Okubaluleke ngakumbi, kudla ngokuvumela abayili ukuba basebenzise izinto zokulinganisa ezincinci kuba i-bushing eyenziweyo inika ukuqina kwendawo apho kufuneka amandla khona, ngaphandle kokongeza ubunzima kwenye indawo. Iigram ezigciniweyo ngoqhagamshelo ngalunye ziphindaphindeka ngokukhawuleza kwisithuthi.

Ukusebenza kakuhle kwenkqubo kunye nesantya: Ukudibanisa imisebenzi emithathu ibe ngamaxesha omjikelo omnye wokusila. Umjikelo oqhelekileyo wokubhoboza nge-thermal friction kunye nokucofa ungagqitywa kwimizuzwana emi-2-6, ngokukhawuleza kakhulu kunoboboza ngokulandelanayo, ukubeka/ukuwelda iinati, kunye nokucofa. Oku kwandisa amandla okusebenza kwimigca ephezulu.

Umgangatho Ophuculiweyo Nokuhambelana: I-TFD ezenzekelayo inika ukuhambelana okugqwesileyo phakathi komngxuma nomngxuma. Le nkqubo iphindaphindwa kakhulu phantsi kwe-CNC elawulwayo okanye iiparameter zerobhothi, inciphisa iimpazamo eziqhelekileyo zomntu ekubekweni kwe-nut ngesandla okanye ekudibaniseni. I-bushing eyenziweyo idala umphezulu wemingxuma ogudileyo, ohlala uvaliwe, ophucula ukumelana nokugqwala kunye nokunamathela kwepeyinti.

Ubunzima beNkqubo kunye neendleko ezincitshisiweyo: Ukususa izixhobo zokondla iinati ezahlukeneyo, izitishi zokuwelda, abalawuli bokuwelda, kunye nokuhlolwa komgangatho okunxulumene noko kunciphisa iindleko zezixhobo ezinkulu, iimfuno zendawo yomgangatho, ubunzima bokugcinwa, kunye nezinto ezisetyenziswayo (akukho cingo/gesi yokuwelda, akukho nati).

Ukuphuculwa koBumbano oluHlanganisiweyo: I-integral bushing yenza inxalenye eqhubekayo yesinyithi kwisixhobo esisisiseko. Akukho mngcipheko wokuba i-nut ikhululeke, ijikelezwe, okanye iwe njengezinto zokubopha ezisebenza ngoomatshini, kwaye akukho ngxaki ye-HAZ efana nokuwelda.

Ukuguquguquka kwezinto: IiCarbide Flow Drill Bits ziphatha ngokufanelekileyo izinto ezahlukeneyo kwiimoto zanamhlanje: intsimbi ethambileyo, intsimbi yeHigh-Strength Low-Alloy (HSLA), i-Advanced High-Strength Steel (AHSS), ii-aluminium alloys (5xxx, 6xxx), kwanezinye izinto ezingenasici. Iingubo zezixhobo (ezifana ne-AlCrN ye-aluminium, i-TiAlN yentsimbi) ziphucula ukusebenza kunye nobomi.

Izicelo eziphambili zokwamkelwa kokuqhuba ngeMoto:

Ii-Enclosures kunye neeTray zeBhetri ye-EV: Mhlawumbi yeyona nto iphambili. Ezi zakhiwo zinkulu, zinodonga oluncinci (ngokuqhelekileyo i-aluminium) zifuna iindawo ezininzi ezinamandla aphezulu, ezingavuziyo ukuze zifakelwe, zigqunywe, zifakwe iipleyiti zokupholisa, kunye nezixhobo zombane. I-TFD inika amandla afunekayo ngaphandle kokongeza ubunzima okanye ubunzima. I-bushing evaliweyo inceda ukuthintela ukungena kwe-coolant.

I-Chassis kunye neeSubframes: Iibrakethi, amalungu anqamlezileyo, kunye neendawo zokufaka iisuspension zixhamla kumandla e-TFD kunye nokumelana nokungcangcazela kwiintsimbi ezibhityileyo nezinamandla aphezulu.

Iifreyimu zezihlalo kunye neendlela: Izinto ezibalulekileyo zokhuseleko ezifuna amandla aphezulu kakhulu okutsala ii-ankile zebhanti kunye neendawo zokufaka eziqinileyo. I-TFD isusa izibophelelo ezinkulu kunye nokuphazamiseka kwe-welding.

Umzimba Omhlophe (BIW): Iibrakethi ezahlukeneyo, izinto zokuqinisa, kunye neendawo zokufakela ngaphakathi kwisakhiwo sesithuthi apho amantongomane ongezelelweyo anzima kwaye ukuwelda akufuneki.

Iinkqubo zokukhupha umoya: Ii-hangers zokufaka kunye nezihlanganisi zokukhusela ubushushu kwintsimbi engagqwaliyo okanye intsimbi eyenziwe nge-aluminium ziyazuza kwimingxuma evaliweyo engamelani nokugqwala kunye nokumelana nokungcangcazela.

Iiyunithi ze-HVAC kunye ne-Ducting: Iindawo zokufakela kunye neephaneli zokufikelela kwinkonzo ezifuna imisonto eqinileyo kwiindawo ezixineneyo zesinyithi.

Imfuneko yeCarbide kwi-TFD yeeMoto:

Ukusebenza kwemveliso yeemoto kuthatha ixesha elide, kufuna ukuthembeka okupheleleyo kwezixhobo kunye nobude bexesha. IiCarbide Flow Drill Bits azixoxiswani. Zimelana namaqondo obushushu aphezulu okungqubana (adla ngokudlula i-800°C/1472°F encotsheni), isantya esiphezulu sokujikeleza, kunye namandla abalulekileyo e-axial adibana namawaka amaxesha ngokutshintsha. Ii-substrates ze-micro-grain carbide eziphucukileyo kunye neengubo ezikhethekileyo (iTiAlN, i-AlTiN, i-AlCrN) zenzelwe izixhobo ezithile zeemoto, ziphucula ubomi bezixhobo kwaye zigcina ukwakheka kwe-bushing okuzinzileyo kunye nomgangatho wemingxuma obalulekileyo kwiinkqubo ezenzekelayo. I-Carbide egcinwe kakuhleIseti yeBit yokuGqiba iThermal Frictioninokucubungula amawaka emingxunya ngaphambi kokuba ifune ukutshintshwa, nto leyo ebonelela ngoqoqosho oluhle kakhulu ngeendleko ngomngxuma ngamnye.

Ukuhlanganiswa kunye nekamva:

Ukuhlanganiswa okuphumelelayo kubandakanya ulawulo oluchanekileyo lwe-RPM, amazinga okutya, amandla e-axial, kunye nokupholisa (ngokudla ngokuba kuncinci ukuqhuma komoya endaweni yokukhukula ukuze kuthintelwe ukucima i-bushing). Iinkqubo zokubeka esweni zilandelela ukuguguleka kwezixhobo kunye neeparamitha zenkqubo zokugcinwa kwangaphambili. Njengoko uyilo lweemoto luqhubekela phambili kwizakhiwo zezinto ezininzi (umz., imizimba ye-aluminium kwizakhelo zentsimbi) kunye nokukhanya okukhulu, imfuno yetekhnoloji ye-Flow Drill iya kukhula ngakumbi. Amandla ayo okwenza imisonto yendawo, eqinileyo kakhulu kwizixhobo ezibhityileyo, ezahlukeneyo, ngokuthe ngqo ngaphakathi kokuhamba kwemveliso ezenzekelayo, ibeka i-Thermal Friction Drilling kungekuphela nje njengendlela eyahlukileyo, kodwa njengomgangatho wexesha elizayo wokuqinisa iimoto okusebenzayo, okunamandla aphezulu. Luguquko oluthe cwaka oludala izithuthi eziqinileyo, ezikhaphukhaphu, i-bushing enye ngexesha.

Ixesha lokuthumela: Agasti-21-2025