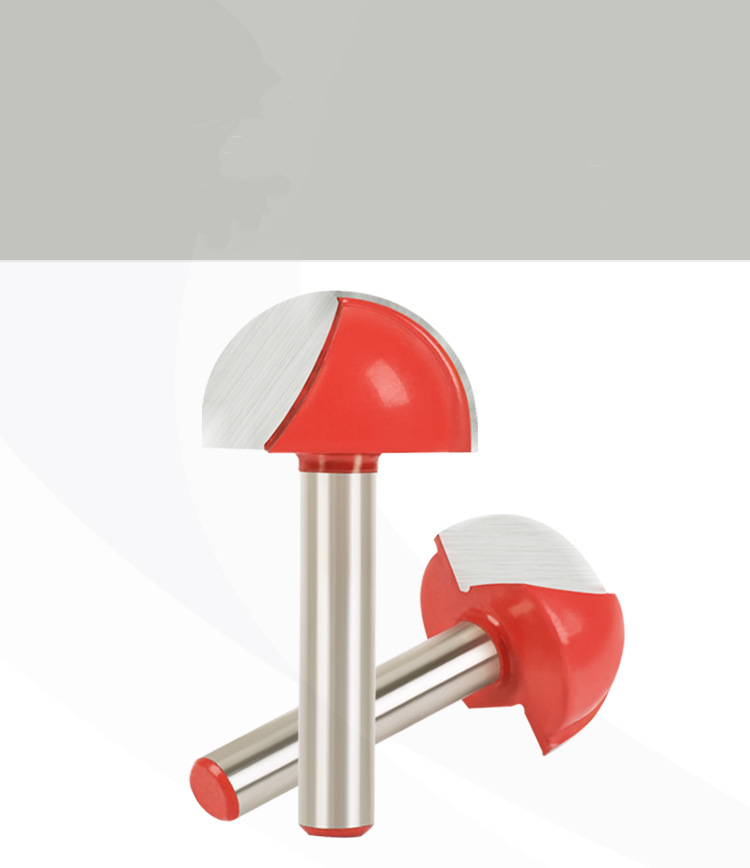

Isixhobo Sokusika Ibhokisi Engundoqo I-Router Bit Round Bottom Round Head Woodworking Cutter

IMBONAKALO

Inkqubo yokuWelda eQhelekileyo kakhulu

Ujongano lugcwele umoya, luqinile kwaye akulula ukuliqhekeza

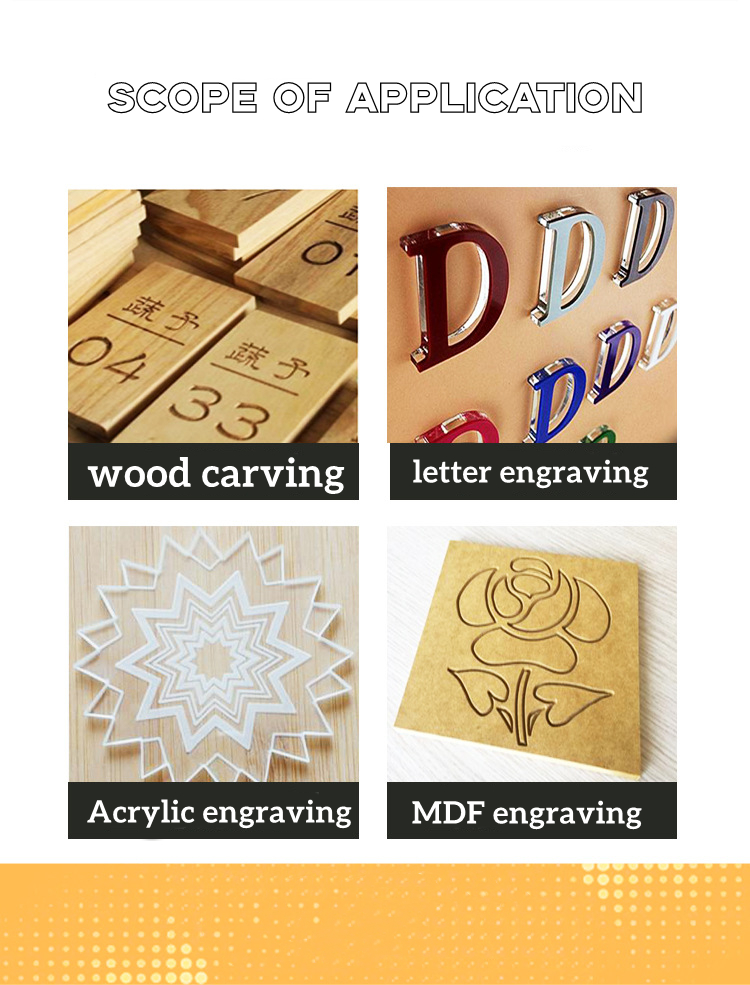

Ifanelekile ukukrola imithi

umbhalo woonobumba

Ukukrola nge-acrylic

Ukukrola kwe-MDF

Ukwenziwa kwentsimbi yeTungsten, ubomi benkonzo ende, ukuxhasa ukwenza ngokwezifiso

Akukho zibher, ukususwa kweetships kakuhle, umphetho wemela obukhali, ukumelana nokuguguleka kunye nokuqina

Uzinzo lwesakhiwo inkqubo evuthiweyo / entle kwaye ihlala ixesha elide

Umgangatho onokulungiselelwa ngokwezifiso uthembekile

Ubomi obude, ukuqina okuphezulu/ukusebenza kakuhle kweendleko

Inkonzo egqibeleleyo, inkonzo esondeleyo

Izinto zentsimbi yeTungsten

Ukusika nokusika iinkuni, i-MDF, njl.njl.

Ububanzi besicelo: imboni yeemoto, i-aerospace, imboni yesikhunta, imboni ye-IT

Ichaphazeke ngokupheleleyo

1. Ukwenziwa ngokwezifiso xa kuyimfuneko / ngaphezulu ngaphandle kweshelufu / umgangatho othembekileyo

2. Izinto ezikhethwayo: Ubunzima bentsimbi ye-tungsten yaseJamani / imela ebukhali kane

3. Ithambile ngaphandle kwe-burrs

Umphezulu uthambile kwaye ukhanya, inani leetships likhulu, kwaye umgca ukhawuleza

4. Ukumelana nokuguguleka kunye nokumelana nokugqwala okuphezulu

Akukho mhlwa kunye nokumelana ne-oxidation kwiindawo ezifumileyo

Indlela yokusebenzisa isixhobo somatshini wokukrola ngomthi:

1. Kucetyiswa izixhobo zokusika ezinemigca emininzi xa kusetyenzwa ibhodi ye-particleboard, njl.njl.

2. Kucetyiswa imela yokukrola idayimani xa kukrolwa isipili se-acrylic.

3. Isiphumo sokusetyenziswa kwesixhobo esisezantsi sokusika, umphezulu ophezulu wemveliso ecutshungulwayo awunazo ii-burrs, kwaye akukho rocker ngexesha lokucubungula.

4. Kwibhodi enezingqimba ezininzi kunye nokulungiswa kwe-splint, kucetyiswa ukusebenzisa i-groove milling cutter enemiphetho emibini ethe tye.

5. Kwibhodi enobunzima obuphezulu kunye nomthi oqinileyo, kucetyiswa ukusebenzisa isixhobo sokusika iintambo.

6. Ukuze ukusika kungabikho burr phezulu nasezantsi, kucetyiswa ukusebenzisa isixhobo sokusika esinomphetho omnye, esinomphetho ophindwe kabini phezulu nasezantsi.

7. Kwi-cork, MDF, virgin wood, PVC, acrylic large-scale deep relief processing, kucetyiswa ukusebenzisa i-single-edged helical ball end milling cutter.

8. Ukuze kulungiswe ngokuchanekileyo ukusika okuncinci, kucetyiswa ukusebenzisa isixhobo sokusika esijikelezileyo.

9. Xa kusikwa iipleyiti ze-aluminium, kucetyiswa ukuba kusetyenziswe isixhobo sokusika i-aluminium esikhethekileyo esinomphetho omnye. Akunakubambeka kwimela ngexesha lokucubungula, isantya esiphezulu kunye nokusebenza kakuhle okuphezulu.

10. Kwi-MDF cutting, kucetyiswa ukusebenzisa i-helical milling cutter enemiphetho emibini enokususwa kweetshiphusi ezinkulu. Inemiqolo emibini yokususa iitshiphusi ezinomthamo ophezulu kunye noyilo olunemiphetho emibini, olungenamsebenzi wokususa iitshiphusi ezilungileyo kuphela, kodwa lukwafezekisa ulungelelwaniso olufanelekileyo lwesixhobo. Xa kusetyenzwa iibhodi eziphakathi nezixineneyo, zineempawu zokungabi mnyama, akukho msi wesiciko, kunye nobomi obude benkonzo.

11. Kwi-acrylic cutting, kucetyiswa ukuba kusetyenziswe i-single-edged spiral milling cutter, ebonakala ngokulungiswa okungenamsi nokungenavumba, isantya esikhawulezayo, ukusebenza kakuhle, ukungabikho kweetships ezinamathelayo, kunye nokusingqongileyo okunobuhlobo ngokwenene. Inkqubo yayo ekhethekileyo yokuvelisa iqinisekisa ukuba i-acrylic ayizukuqhuma. , Ipateni yemela entle kakhulu (nokuba ingenayo ipateni yemela), umphezulu uthambile kwaye uthambile. Umphezulu ocudisiweyo kufuneka ufezekise isiphumo esibandayo, kwaye kucetyiswa ukuba kusetyenziswe i-double-edged three-edged spiral milling cutter.