I-HRC65 Black Nano-Tech Stainless Processing Flat End Mill

Uphawu:

1. Amasuntswana amancinci avela kwintsimbi yeTungsten + izixhobo zemveliso ezingenisiweyo.

Sisebenzisa izinto ezisisiseko ze-tungsten carbide eziyi-100%, kwaye asivumi ukusebenzisa izinto ezisetyenzisiweyo okanye izinto ezingcoliswayo.

2. Singenise oomatshini be-SACCKE abavela eJamani ukuze basilwe kakuhle ukuze sifumane ukuchaneka okuzinzileyo kunye nokugqitywa okuphezulu.

3.Ulwahlulo olungalinganiyo kunye ne-engile ye-helix engalinganiyo ukuze kuthintelwe ukurhawuzelelwa kunye nokunyusa ukugqitywa komphezulu weendawo ezicutshungulwayo.

4.HRC65.

5. I-ALoCa coating evela eSwitzerland, i-insulation yobushushu kunye nokumelana nobushushu obuphezulu, i-milling enobunzima obuphezulu.

Ubunzima bokugquma obuyi-~3500HV kunye nobushushu obuchasene neoksijini obuyi-950 degrees.

6. Inkqubo yenyathelo/iflute epheleleyo yokugaya ejikelezayo, ukususwa kweetshiphusi ezigudileyo ngexesha lokusika ngesantya esiphezulu, akukho kuqokelelwa kweetshiphusi/akukho kuqokelela kweetshiphusi, kuphucula kakhulu ukusebenza kakuhle kwemveliso kunye nokuphucula ukugqitywa kwemisebenzi.

| Iifluti | 4 | Izinto eziphathekayo | I-alloy ye-titanium, intsimbi engagqwaliyo | ||||||||||

| Uhlobo | Uhlobo lwentloko ethe tyaba | Ukuqina | I-HRC65 | ||||||||||

| Iphakheji |

| Uphawu | I-MSK | ||||||||||

| Ububanzi beFlute(mm) | Ubude beFlute (mm) | Ububanzi be-Shank(mm) | Ubude (mm) | ||||||||||

| 1 | 3 | 4 | 50 | ||||||||||

| 1.5 | 4 | 4 | 50 | ||||||||||

| 2 | 6 | 4 | 50 | ||||||||||

| 2.5 | 7 | 4 | 50 | ||||||||||

| 3 | 8 | 4 | 50 | ||||||||||

| 4 | 11 | 4 | 50 | ||||||||||

| 5 | 13 | 6 | 50 | ||||||||||

| 6 | 15 | 6 | 50 | ||||||||||

| 8 | 20 | 8 | 60 | ||||||||||

| 10 | 25 | 10 | 75 | ||||||||||

| 12 | 30 | 12 | 75 | ||||||||||

Sebenzisa:

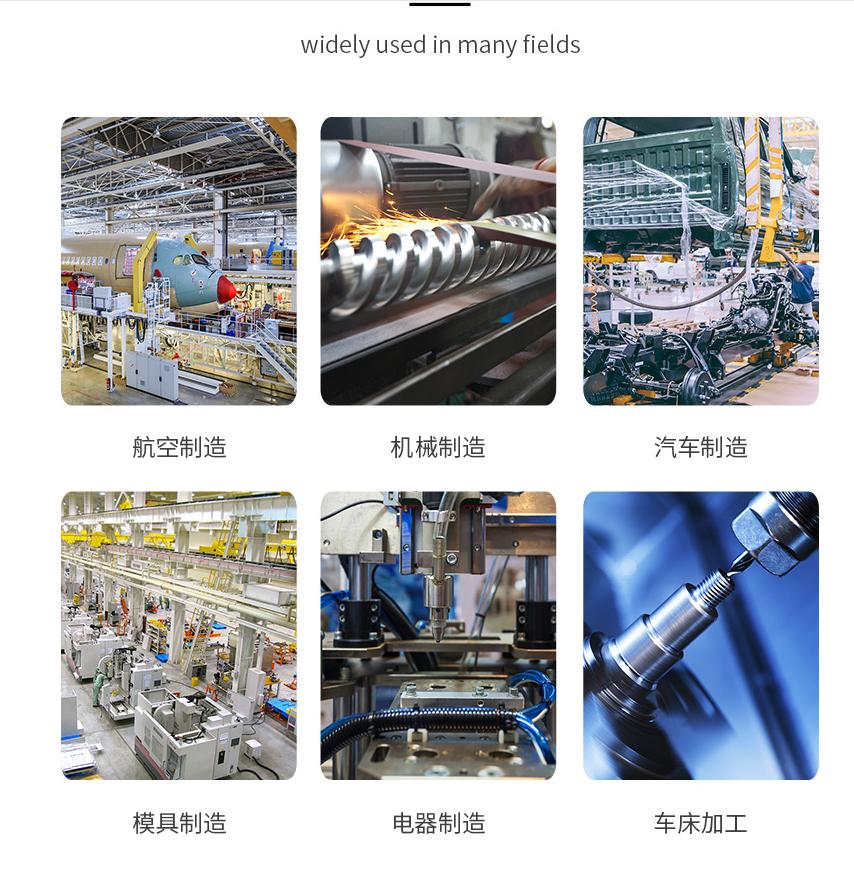

Isetyenziswa kakhulu kwiindawo ezininzi

Ukuveliswa kweenqwelo moya

Imveliso yoomatshini

Umenzi weemoto

Ukwenza isikhunta

Ukuveliswa koMbane

Ukucubungula nge-lathe