I-HRC55 Metric Carbide Step Drill yesinyithi

Iimbonakalo:

Ukubhola kunye nokuxovula

Ukususwa kweetshiphusi ngokutyibilikayo

Intsimbi ye-tungsten ekhethwayo

Ifanelekile ukugrumba umngxuma wenyathelo ngaxeshanye

Inzuzo:

1. Iifliti ezinkulu ze-chip zinokuqinisekisa ngokufanelekileyo ukususwa kwe-chip okugudileyo kwaye ziphucule ukusebenza kakuhle kwe-machining

2. I-AlTiN/TiSiN/AlTiSiN/TiN/ngaphandle kokugquma, zonke ziyafumaneka

3. Ikhabhayithi eqinisiweyo

Isebenzisa izinto ezisisiseko zentsimbi ye-tungsten ecolekileyo, inobunzima obuphezulu kunye namandla angcono okugoba, isixhobo asigugi kakhulu, kulula ukusiqhekeza nokusiqhekeza, kwaye sisebenza ixesha elide.

4. Kulula ukuyisebenzisa i-chamfering

Uyilo lwe-shank ene-chamfered kulula ukuyibamba.

Iingcebiso Zokunyamekela I-Step Drill Bit

Ukuba ungakwazi ukunyamekela isixhobo sakho ngokufanelekileyo, siya kusebenzela injongo yaso ixesha elide. Ngale ndlela, akuyi kufuneka uchithe imali eyongezelelweyo ekuthengeni ikhithi entsha kungekudala. Ngoku, ngaba kunzima kakhulu ukunyamekela ikhithi yokubhola ngonyawo? Akunjalo konke konke, kulula kangangoko kunokwenzeka. Ngoku, masifunde indlela yokwenza ngokuchanekileyo.

Inyathelo 1: Kufuneka ucoce iziqwenga rhoqo ngexesha lomsebenzi. Ngaphandle koko, kuya kuba lula ukonakala ngokukhawuleza kunokuba bekulindelwe.

Inyathelo lesi-2: Kuya kufuneka usule iqhekeza xa ugqibile umsebenzi.

Inyathelo lesi-3: Khuhla nayiphi na inkunkuma ekwiziqwenga usebenzisa ibrashi yamazinyo.

Inyathelo lesi-4: Ungafaka ioyile yomatshini emva koko kwiibhiti.

| Uhlobo lwesandla | Isibambo esithe tye | Izinto zokusebenzela | Izinto zesinyithi ezifana nentsimbi, ubhedu, i-aluminium, intsimbi ye-alloy, intsimbi ephosiweyo, njl. |

| Uphawu | I-MSK | Izinto eziphathekayo | I-Carbide |

| Umsebenzi | Ukubhoboza imingxunya enyukayo, ii-chamfers ezibophayo | Ububanzi beNtloko encinci (mm) | 3.4-14.0 |

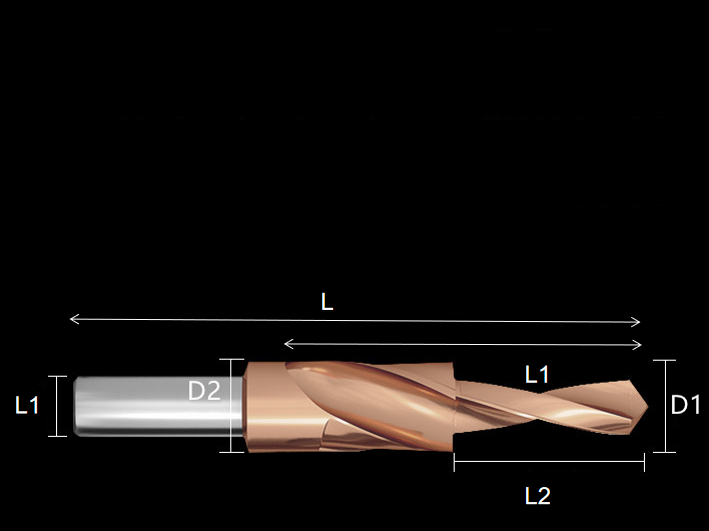

| D1(mm) | D2(mm) | L(mm) | I-L1(mm) | L2(mm) |

| 3.4 | 6.5 | 65 | 35 | 13 |

| 4.5 | 8.0 | 75 | 42 | 18 |

| 5.5 | 9.5 | 85 | 50 | 22 |

| 6.6 | 11.0 | 90 | 53 | 25 |

| 9.0 | 14.0 | 95 | 53 | 28 |

| 11.0 | 17.5 | 105 | 63 | 30 |

| 14.0 | 20.0 | 110 | 68 | 32 |