Isixhobo seLathe seCNC Isixhobo sokubhola isinyithi Isixhobo sokubhola esitsolo

Iibhithi Zokubhola Ezingama-90 Degrees Izixhobo Zokubhola Ezingama-90 zisetyenziselwa ukuqala umngxuma ogqojozwe ngokwesiko. Ngokusebenzisa iibhithi zokubhola ezima-engile ezifanayo nezo zebhithi yokubhola eqhelekileyo eza kusetyenziswa, kwenziwa ukubotshwa kwindawo echanekileyo yomngxuma. Oku kuthintela ukubhola ukuba kuhambe kwaye kuthintele umonakalo ongafunekiyo kwindawo yokusebenza. Iibhithi zokubhola ezima-spot zisetyenziswa kwimisebenzi yesinyithi efana nokubhola ngokuchanekileyo kumatshini we-CNC.

Uphawu:

1. Iimveliso ezikhoyo azigqunywanga, kukho iintlobo ngeentlobo zokugqunywa ezifumaneka ngokweemfuno zakho.

2. Ukubhola amabala kunokwenza zombini ukujika phakathi kunye nokujika. Ukujika phakathi kunye nokujika kwe-chamfer kwenziwa ngokuchanekileyo ngaxeshanye ukuphucula ukusebenza kakuhle kokucutshungulwa.

3. Ifanelekile kwintsimbi eqhelekileyo, intsimbi ye-alloy, iintsimbi eziqinisiweyo, intsimbi ephosiweyo, kunye ne-aluminium alloy, njl.njl.

Isaziso:

1. Ukugrumba okuneendawo ezizinzileyo kungasetyenziselwa kuphela ukukhomba okuzinzileyo, ukukroba, kunye nokukroba, kwaye akufuneki kusetyenziselwe ukugrumba

2. Qiniseka ukuba uvavanya ukugoba kwesixhobo ngaphambi kokuba usisebenzise, nceda ukhethe ukulungiswa xa sidlula i-0.01mm

3. Ukugrumba okune-fixed-point kwenziwa ngokugrumba okune-fixed-point + chamfering kube kanye. Ukuba ufuna ukugrumba umngxuma we-5mm, ukhetha ngokubanzi i-6mm fixed-point drill, ukuze ukugrumba okulandelayo kungaphambuki, kwaye kufumaneke i-0.5mm chamfer.

| Izinto zokusebenzela | I-Copper, i-aluminium, i-aluminium alloy, i-magnesium alloy, i-zinc alloy kunye nezinye izinto | Izinto eziphathekayo | I-Tungsten |

| I-engile | Idigri ezingama-90 | Iflethi | 2 |

| Ukwaleka | Yenzelwe wena | Uphawu | I-MSK |

| Ububanzi | Iflethi | Ubude obupheleleyo (mm) | I-engile | Ububanzi be-Shank(mm) | ||||

| 3 | 2 | 50 | 90 | 3 | ||||

| 4 | 2 | 50 | 90 | 4 | ||||

| 5 | 2 | 50 | 90 | 5 | ||||

| 6 | 2 | 50 | 90 | 6 | ||||

| 8 | 2 | 60 | 90 | 8 | ||||

| 10 | 2 | 75 | 90 | 10 | ||||

| 12 | 2 | 75 | 90 | 12 | ||||

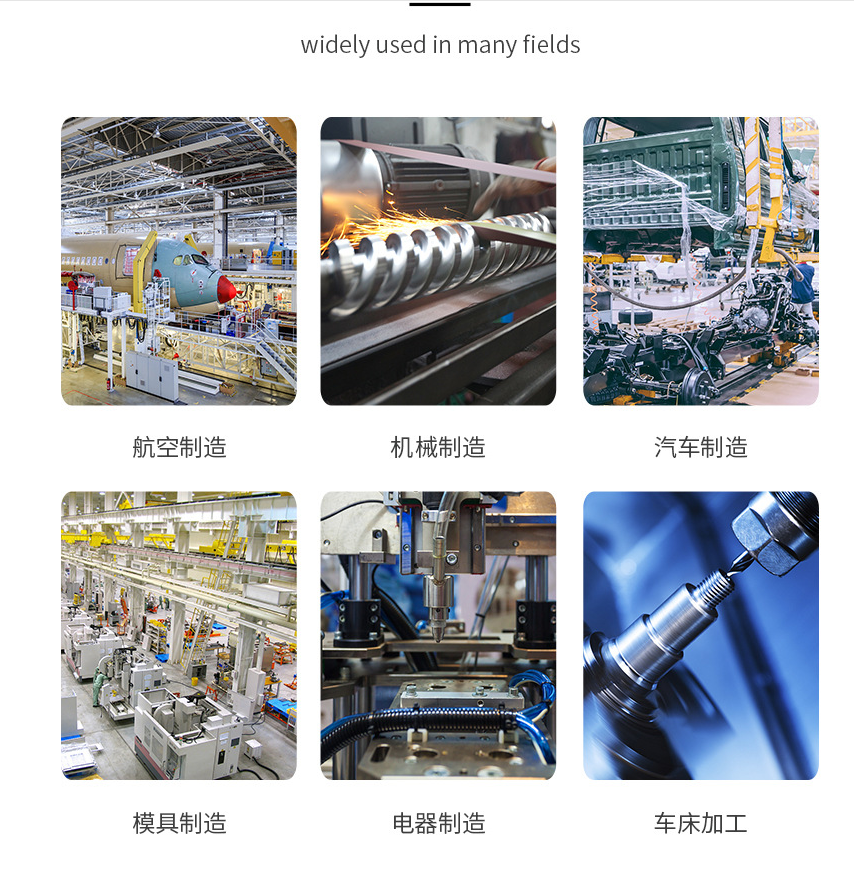

Sebenzisa:

Ukuveliswa kweenqwelo moya

Imveliso yoomatshini

Umenzi weemoto

Ukwenza isikhunta

Ukuveliswa koMbane

Ukucubungula nge-lathe