Katleho e kgolo tlhahisong e shebane le dikotwana tse ntjha tsa ho tjheka phallo (tse tsejwang hape e ledrill ea mocheso oa khohlano ea mochesos kapa flowdrill) e fetola tsela eo liindasteri li hlahisang likhoele tse matla le tse tšepahalang ka har'a tšepe e tšesaane le liphaephe. Theknoloji ena e thehiloeng khohlanong e felisa tlhoko ea ho cheka le ho thaepa ka mokhoa oa setso, e fanang ka melemo e meholo matla, lebelo le ts'ebeliso e ntle ea litšenyehelo, haholo-holo makaleng a likoloi, a lifofane le a elektroniki.

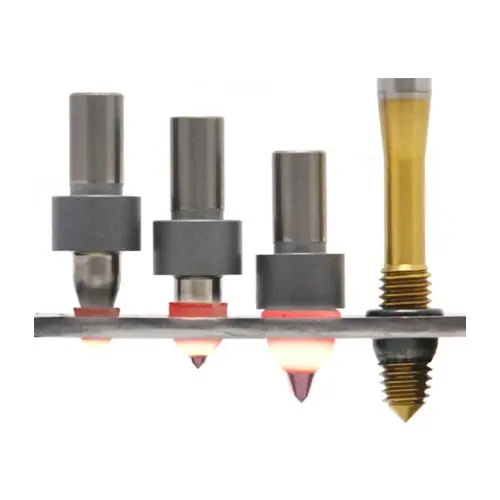

Boqapi ba mantlha bo lutse ts'ebetsong e ikhethang e nolofalitsoeng ke likarolo tsena tse ikhethileng. Ho fapana le li-drill tse tloaelehileng tse sehang le ho tlosa thepa, karolo ea drill e phallang e hlahisa mocheso o matla ka ho kopanya lebelo le phahameng haholo la ho potoloha le khatello e laoloang ea axial. Ha ntlha ea tungsten carbide e bōpehileng ka ho khetheha e kopana le bokaholimo ba mosebetsi, khohlano e futhumatsa ka potlako tšepe e ka tlas'a eona - hangata tšepe, tšepe e sa hloekang, aluminium, kapa li-alloy tsa koporo - ho ea boemong ba eona ba polasetiki (hoo e ka bang 600-900°C ho latela thepa).

Ho phunya hona ho entsoeng ka sekhomaretsi ke tšobotsi ea bohlokoa. Hangata ho atoloha ho fihlela makhetlo a mararo ho feta botenya ba pele ba thepa ea motheo. Mohlala, ho kenya khoele lakane e teteaneng ea 2mm ho fella ka khoele e tiileng e bolelele ba 6mm. Sena se eketsa botebo ba ho kenella ha khoele haholo ho feta seo ho ka khonehang ka botenya ba thepa e tala feela.

Kamora ho thehoa ha sehlahla, ts'ebetso hangata e tsoela pele hantle. Ho pompoa ho tloaelehileng ho latelakarolo ea ho phunya phallo, ebang ke hang-hang ka potoloho e tšoanang ea mochini (lisebelisoang tse lumellanang) kapa ts'ebetsong e latelang. Pompo e seha likhoele tse nepahetseng ka ho toba ka har'a sekhoeng se secha se entsoeng, se nang le mabota a teteaneng. Kaha sekhoeng ke karolo ea sebopeho sa pele sa thepa ea pele, eseng sehokelo se eketsehileng, likhoele tse hlahisoang li na le ho nepahala ho phahameng le matla a phahameng.

Melemo ea Bohlokoa ea ho Khanna ho Amohela Bana:

Matla a sa Bapisoeng le a Thepa e Nyenyane: Sekoti sa 3x se fana ka kgokelo e ntle haholo ya khoele ha se bapiswa le ho tobetsa botenya ba motheo ka ho toba kapa ho sebedisa di-insert.

Lebelo le Bokgoni: E kopanya ho etsa masoba le ho bopeha ha dithupa tshebetsong e le nngwe e potlakileng haholo (hangata metsotswana ka lesoba), e fedisa mehato e arohaneng ya ho tjheka, ho tlosa dithunya le ho kenya.

Poloko ea Thepa: Ha ho na li-chip tse hlahisoang nakong ea mohato oa ho cheka phallo, e leng se fokotsang litšila tsa thepa.

Manonyeletso a Tiisitsoeng: Thepa e tlositsoeng e phalla ka thata ho potoloha lesoba, hangata e etsa lenonyeletso le sa dutleng le loketseng bakeng sa ts'ebeliso ea metsi kapa khatello.

Lisebelisoa tse Fokolitsoeng: E felisa tlhoko ea linate, linate tsa weld, kapa li-insert tse nang le riveted, e leng se nolofatsang BOM le tsamaiso ea thepa.

Mokhoa oa ho Hloekisa: Li-chip tse fokolang 'me ha ho hlokahale ho khaola maro a mangata lits'ebetsong tse ngata (ka linako tse ling ho tlotsa ho sebelisoa bakeng sa bophelo ba bit kapa thepa e itseng).

Litšebeliso li Atile: Theknoloji ena e ntse e hohela ka potlako hohle moo thepa e bobebe e tšesaane e hlokang likhokahano tse matla tse nang le khoele:

Likoloi: Literei tsa betri ea koloi ea motlakase, likarolo tsa chassis, li-bracket, litsamaiso tsa mosi, liforeimi tsa litulo.

Sefofane: Diphanele tsa kahare, diphaephe tsa mokero, dibracket tse bobebe tsa meaho.

Lisebelisoa tsa elektroniki: Liraka tsa seva, liphanele tse koetsoeng, lisinki tsa mocheso.

HVAC: Likhokahano tsa li-duct tsa tšepe ea lakane, li-bracket.

Thepa ea ka tlung le Lisebelisoa: Liforeimi tsa mohaho tse hlokang lintlha tse patehileng le tse matla tsa ho khomarela.

Bahlahisi ba di-drill bits tsa phallo ba tswela pele ho ntlafatsa dijiometri, dikobo le dibopeho tsa thepa ho eketsa bophelo ba disebediswa, ho ntlafatsa tshebetso hodima di-alloy tse tswetseng pele, le ho ntlafatsa tshebetso ya boiketsetso. Ha diindasteri di ntse di phehella ho kganna le ho ntlafatsa bokgoni ba tlhahiso, ho tjheka ka motjheso, ho tsamaiswa ke boqapi bo botjha.seporo sa phallobit, e ipaka e le tharollo ea bohlokoa bakeng sa ho theha likhoele tse sebetsang hantle moo pele li neng li sa khonehe kapa li sa sebetse. Nako ea ho loana le likhoele tse fokolang maqepheng a masesaane e suthela matla le bonolo ba lihlahla tse entsoeng ka khohlano sebaka.

Nako ea poso: Phupu-30-2025