Liindastering moo ho nepahala, lebelo le ho tenyetseha ha thepa ho leng bohlokoa, Li-Tungsten Carbide Rotary Burrs tse nang le Lihlooho tsa ho Sila tsa Tšepe e le 'Ngoe le e 'Meli li hlahella e le tse fetolang lintho. Li etselitsoe ho fihlela litlhoko tse matla tsa tlhahiso ea sejoale-joale, ho etsa hlobo le boqhetseke ba matsoho, lisebelisoa tsena tse tsoetseng pele tsa rotary li fana ka ts'ebetso e ke keng ea bapisoa ho pholletsa le litšepe le tse seng tsa tšepe ka ho tšoana. Ebang ke ho hloekisa tšepe e nang le khabone e ngata kapa ho bopa jade ka boqhetseke,Sete ea Carbide Rotary Burre kopanya ho tšoarella le ho nepahala, e leng se etsang hore e be tlatsetso ea bohlokoa bakeng sa li-workshop, lifektheri le li-studio tsa boqapi lefatšeng ka bophara.

Ho Feto-fetoha ha Lintho Tse sa Bapisoeng

Matla a hlalosang a tsenaLi-burrs tsa Rotary tsa Tungsten CarbideHo itshetlehile bokgoning ba tsona ba ho sebetsana le mefuta e sa tlwaelehang ya thepa. Ho tloha ditshepeng tse boima tse kang tshepe, tshepe e entsweng ka foreshe, tshepe e nang le khabone e ngata, tshepe e kopantsweng le tshepe e sa ruseng ho isa dinthong tse bonolo tse kang koporo, aluminium, mmabole, jade le lesapo, disebediswa tsena di ikamahanya le maemo ka ho hlaka. Ho tenyetseha hona ho fedisa tlhoko ya disebediswa tse ngata tse ikgethang, ho nolofatsa mesebetsi diindastering tse kang tlhahiso ya dikoloi, boenjiniere ba difofane, moralo wa mabenyane le ho betla majwe.

Mofuta wa Double Metal Grinding Head o ntlafatsa ho ikamahanya hona le maemo le ho feta. Ka ho kopanya dikereiti tse pedi tse fapaneng tsa carbide kapa dijiometri ka hara burr e le nngwe, basebedisi ba ka sebetsana le mesebetsi e kopantsweng—jwalo ka ho kgwahlapisa le ho qeta—ntle le ho fetola disebediswa. Tshebetso ena e habeli e bohlokwa haholo ho etseng hlobo, moo dikoti tse rarahaneng di hlokang ho tloswa ha thepa ka matla le ho hlahiswa ha dintlha tse ntle haholo.

Qetello e Phahameng le Bokhoni bo Nepahetseng bo Phahameng

Li entsoe ka bokhabane, li-rotary burrs tsena li hlahisa liphetho tse boreleli haholo ka boiteko bo fokolang. Meeli ea tsona ea ho seha ea tungsten carbide e sitsitsoeng ka nepo e netefatsa hore e kopana hantle le lintho tse sebetsang, e fokotsa lerata le ho fokotsa ts'ebetso ea kamora ho sebetsa. Sena se fella ka:

Boleng bo phahameng ba bokaholimo: Finyella liphetho tse kang seipone holim'a litšepe kapa u behe lintho tse se nang sekoli holim'a thepa e robehang joalo ka 'mabole le lesapo.

Dijiometri tse rarahaneng: Etsa dikoti tse rarahaneng tsa hlobo, ho fokotsa le ho etsa dibopeho tse fapaneng ka ho nepahala ha submillimeter.

Mosebetsi o fokoditsweng wa bobedi: Ho fedisa tlhoko ya ho sanda kapa ho polisha dikopong tse ngata, e leng se bolokang nako le ditjeo tsa basebetsi.

Tšepe e le 'NgoeHlooho ea ho SilaKhetho e ipabola mesebetsing e khethehileng e hlokang ketso e tšoanang ea ho seha, joalo ka ho tlosa libomo tse phuthetsoeng kapa ho ntlafatsa likarolo tsa enjene. Ho sa le joalo, moralo oa lihlooho tse peli o fana ka phetoho e ke keng ea lekanngoa bakeng sa merero ea mekhahlelo e mengata.

E Hahiloe bakeng sa Lebelo, E Entsoe bakeng sa Mamello

Li ntlafalitsoe bakeng sa ho sebelisoa le lisebelisoa tsa motlakase, lisebelisoa tsa pneumatic, kapa mechine ea CNC, lifaele tsena tse potolohang li sebetsa hantle ka lebelo le tlohang ho 6,000 ho isa ho 50,000 RPM. Mefuta ena e pharaletseng e netefatsa hore lia lumellana le lisebelisoa tse fapaneng, ho tloha ho li-grinder tsa die tse tšoaroang ka letsoho ho ea litsing tsa machining tsa indasteri. Likarolo tsa bohlokoa li kenyelletsa:

Ho hanyetsa mocheso: Ho mamella mocheso ha Tungsten carbide ho thibela ho fetoha ha mocheso esita le nakong ea tšebeliso e telele ea lebelo le phahameng.

Nako e Telele ea Bophelo: Lisebelisoa tsa HSS tse sebetsang hantle ka makhetlo a 20, li-burrs tsena li hanela ho tsofala, ho qhetsoha le ho bola.

Phokotso ea ho thothomela: Lihlooho tse silang tse leka-lekaneng li ntlafatsa botsitso, li fokotsa mokhathala oa mosebelisi le ho ntlafatsa taolo.

Likopo ho pholletsa le Liindasteri

Tlhahiso ea Hlobo le ho Shoa: E phethahetse bakeng sa ho etsa liforomo tsa ente tse nepahetseng haholo, li-dies tsa stamping, kapa lisebelisoa tsa sefofane.

Tlhahiso ea Tšepe: Likarolo tsa ho tlosa litšila, chamfer, le sebopeho mererong ea tšepe ea likoloi, ea kaho ea likepe, kapa ea meaho.

Bonono le Setšoantšo: Betla meralo e rarahaneng hore e be lejoe, lesapo, kapa litšepe tsa bohlokoa ntle le ho beha thepa e bonolo kotsing.

Tlhokomelo le Tokiso: Lokisa likarolo tsa mechini, lihlooho tsa enjene ea koung, kapa lokisa likarolo tsa motsoako ka ho nepahala ha opereishene.

Ho Etsa Mabenyane: Ngola dipaterone tse ntle hodima di-setting tsa kgauta, silefera, kapa majwe a bohlokwa.

Litlhaloso tsa Tekheniki

Thepa: Carbide ea tungsten ea boleng bo holimo e nang le cobalt binder bakeng sa ho tiea le ho hanyetsa ho tsofala.

Boholo ba Shank: 3mm (e lumellana le lisebelisoa tse ngata tse potolohang le li-collet).

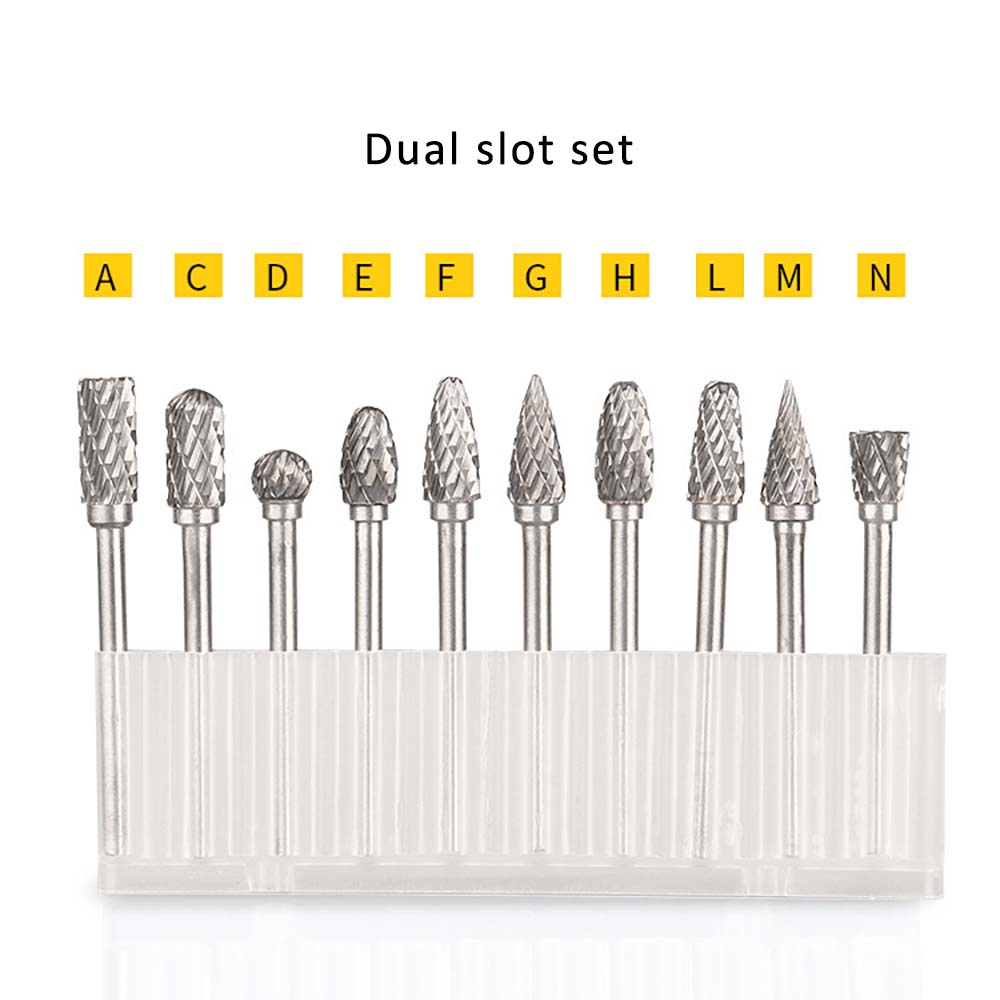

Mefuta ea Hlooho ea ho Sila: E khaotsoeng ka lesoba le le leng (bakeng sa ho qeta hantle) le e khaotsoeng habeli (bakeng sa ho tlosa setoko ka matla).

Ho Latela Melao ea Polokeho: E fihlela litekanyetso tsa ISO 9001 le ANSI, ka li-shank tse matlafalitsoeng ho thibela ho robeha.

Hobaneng o lokela ho khetha Carbide Rotary Burr Set?

Ho Bokgoni ba Ditjeo: Fokotsa ditjeo tsa pokello ya disebediswa ka sete e le nngwe e sebetsanang le thepa le mesebetsi e fapaneng.

Ho Boloka Nako: Fetoha pakeng tsa ho lokisa le ho qeta ka metsotsoana, ka lebaka la moralo oa lihlooho tse peli.

Moralo oa Ergonomic: Liaparo tse bobebe, tse thibelang ho thella, le botsitso bo ntlafalitsoeng li ntlafatsa boiketlo ba mosebelisi nakong ea tšebeliso e telele.

Ntlafatsa Seboka sa Hao sa Mosebetsi Kajeno

Fumana hore na li-Burr tsa rona tsa Rotary tsa Tungsten Carbide Rotary Head tse le 'Ngoe le tse peli tse Silang li ka phahamisa tlhahiso le ho nepahala ha hau joang.https://www.mskcnctools.com/ho hlahloba maqephe a data a tekheniki, ho kopa disampole, kapa ho ikopanya le sehlopha sa rona sa litsebi bakeng sa likhothaletso tse etselitsoeng uena.

Nako ea poso: Mots'eanong-12-2025