Leeto le sa khaotseng la ho ea likoloing tse bobebe, tse matla le tse sebetsang hantle haholoanyane, haholo-holo ka kholo e matla ea Likoloi tsa Motlakase (li-EV), le beha khatello e kholo tlhahisong ea likoloi. Mekhoa ea setso ea ho theha likhokahano tse matla tse nang le likhoele ka tšepe e tšesaane - e leng ntho ea bohlokoa ea 'mele ea likoloi tsa sejoale-joale, liforeimi le li-enclosure - hangata e kenyelletsa li-fasteners tse eketsehileng joalo ka linate tsa weld kapa linate tsa rivet. Tsena li hlahisa ho rarahana, boima, lintlha tse ka bang teng tsa ho hloleha, le linako tse liehang tsa potoloho. Kenya Thermal Friction Drilling (TFD) le lisebelisoa tsa eona tse khethehileng -Karolo ea ho Cheka ea Khabide ea Phallos le Thermal Friction Drill Bit Sets – theknoloji e fetolang mela ya tlhahiso ya dikoloi ka potlako ka ho iketsetsa tlhahiso ya dikgwele tse kopaneng, tse matla haholo ka ho toba ka hara thepa e tshesane.

Bothata ba ho Tiisa Likoloi: Boima, Matla, Lebelo

Baenjiniere ba likoloi ba lula ba loantšana le pherekano ea matla a boima le boima. Litšepe tse tšesaane, tse matla haholo le li-alloy tsa aluminium lia hlokahala bakeng sa ho fokotsa boima ba likoloi le ho ntlafatsa ts'ebetso ea mafura kapa mefuta ea EV. Leha ho le joalo, ho theha likhoele tse tšepahalang tse jarang mojaro likarolong tsena tse tšesaane ho na le bothata:

Ho Kopana ho Lekanyeditsweng: Ho kenya khoele ka tsela ya setso ho fana ka kgokelo e nyane haholo, e leng se etsang hore ho be le matla a fokolang a ho hula le ho ba kotsing ya ho hlobola.

Ho rarahana le Boima bo Eketsehileng: Ho tjheseletsa linate, linate tsa clinch, kapa linate tsa rivet ho eketsa likarolo, ho hloka ts'ebetso ea bobeli (ho tjheseletsa, ho tobetsa), ho eketsa boima, le ho hlahisa libaka tse ka bang teng tsa ho bola kapa mathata a taolo ea boleng.

Mathata a Ts'ebetso: Ho tjheka ka thoko, ho kenya/ho hokela sehokelo, le mehato ya ho thaepa e diehisa mela ya tlhahiso e nang le bophahamo bo hodimo.

Mocheso le ho Sotha: Linate tsa ho tjheseletsa li hlahisa mocheso o moholo, o ka 'nang oa sotha liphanele tse tšesaane kapa oa ama thepa ea thepa Sebakeng se Amehileng ke Mocheso (HAZ).

Phallo ea ho Sebetsas: Tharollo e Iketsang Moleng

Ho Cheka ha Thermal Friction, ho kopantsoeng le litsi tsa CNC machining, lisele tsa roboto, kapa mechini e inehetseng ea multi-spindle, ho fana ka karabo e khahlisang:

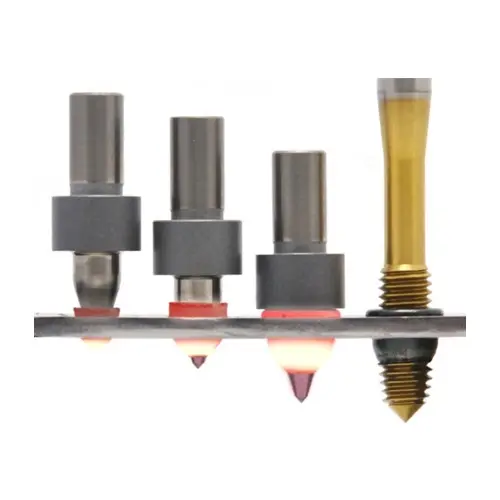

Matla a Ts'ebetso e le 'Ngoe: Boselamose ba mantlha ba TFD bo lutse ho kopanyeng ho tjheka, ho thehwa ha bushing, le ho kenya tshebetsong e le 'ngoe e se nang sekoli, e iketsahallang. Carbide Flow Drill Bit e le 'ngoe, e potolohang ka lebelo le phahameng (hangata 3000-6000 RPM bakeng sa tšepe, e phahameng bakeng sa aluminium) tlas'a matla a maholo a axial, e hlahisa mocheso o matla oa khohlano. Sena se etsa hore tšepe e be polasetiki, e lumelle sebopeho se ikhethang sa bits ho phalla le ho tlosa thepa sebakeng sa eona, ho etsa bushing e se nang sekoli, e kopaneng e ka bang makhetlo a 3 ho feta botenya ba lakane ea pele.

Ho Tlanya Hang-hang: Ha Flow Drill e hula morao, pompo e tloaelehileng (hangata e le holim'a sesebelisoa se le seng tsamaisong ea phapanyetsano ea othomathiki kapa spindle ea bobeli e lumellanang) e latela hang-hang, e khaola likhoele tse nepahetseng haholo ka har'a bushing ena e ncha e entsoeng, e nang le mabota a teteaneng. Sena se felisa ho sebetsana le ts'ebetso lipakeng tsa ts'ebetso 'me se fokotsa nako ea potoloho haholo.

Ho Kopanya Robotic: Li-Bit tsa Thermal Friction Drill Sets li loketse matsoho a roboto hantle. Bokhoni ba tsona ba ho etsa ts'ebetso eohle ea ho theha khoele ka tsela e le 'ngoe ea lisebelisoa (ho phunya fatše, ho etsa bushing, ho hula morao, ho kokota fatše, ho hula morao) bo nolofatsa lenaneo le ts'ebetso ea roboto. Liroboto li ka beha sesebelisoa hantle holim'a li-contour tse rarahaneng meahong e tšoeu ea 'mele (BIW) kapa likopanong tse nyane.

Hobaneng Bahlahisi ba Likoloi ba Amohela Mekgwa ya ho Fokotsa Phallo:

Matla a Khoele a Eketsehileng ka ho Fetisisa: Ena ke molemo o moholo ka ho fetisisa. Likhoele li kopanya sehlahla se teteaneng (mohlala, ho etsa sehlahla se bolelele ba 9mm ho tloha ho lakane ea 3mm), e leng se fellang ka matla a ho hula le ho hlobola ao hangata a fetang a linate tsa weld kapa linate tsa rivet. Sena se bohlokoa bakeng sa likarolo tsa bohlokoa tsa polokeho (liankora tsa lebanta la setulo, li-suspension mounts) le libaka tse thothomelang haholo.

Phokotso e Kholo ea Boima: Ho tlosa nate ea weld, nate ea rivet, kapa nate ea clinch ka boeona ho tlosa boima. Habohlokoa le ho feta, hangata ho lumella baqapi ho sebelisa thepa e tšesaane ea gauge ka kakaretso kaha bushing e entsoeng e fana ka matlafatso ea sebakeng seo moo matla a hlokahalang, ntle le ho eketsa boima libakeng tse ling. Ligrama tse bolokiloeng ka khokahano ka 'ngoe li ata ka potlako ho pholletsa le koloi.

Bokgoni ba Ts'ebetso bo sa Bapisoeng le Lebelo: Ho kopanya mesebetsi e meraro ka linako tse le 'ngoe tsa potoloho ea ho thiba. Potoloho e tloaelehileng ea ho cheka ka mocheso le ho thiba e ka phethoa ka metsotsoana e 2-6, e potlakileng haholo ho feta ho thiba ka tatellano, ho beha/ho tjheseletsa linate, le ho thiba. Sena se eketsa phallo ea matla meleng e nang le molumo o phahameng.

Boleng bo Ntlafalitsoeng le ho Tsitsisa: TFD e iketsang e fana ka botsitso bo ikhethang ho tloha lesobeng ho ea ho lesoba. Ts'ebetso ena e ka phetoa haholo tlas'a liparamente tse laoloang tsa CNC kapa tsa roboto, e fokotsang liphoso tse tloaelehileng tsa batho ho beheng linate ka letsoho kapa ho tjheseletsa. Sehlahla se entsoeng se etsa bokaholimo ba lesoba bo boreleli, hangata bo koetsoeng, bo ntlafatsang ho hanyetsa mafome le ho khomarela pente.

Ho Fokotsa Tharollo le Litšenyehelo tsa Sistimi: Ho tlosa li-feeder tse arohaneng tsa linate, liteishene tsa ho tjheseletsa, balaoli ba ho tjheseletsa, le liteko tsa boleng tse amanang le tsona ho fokotsa litšenyehelo tsa lisebelisoa tsa motse-moholo, litlhoko tsa sebaka sa fatše, ho rarahana ha tlhokomelo, le lintho tse sebelisoang (ha ho terata/khase ea ho tjheseletsa, ha ho linate).

Botšepehi bo Ntlafetseng ba Kopanelo: Sekotjana se kopaneng se etsa karolo e tsoelang pele ea tšepe ea thepa ea motheo. Ha ho na kotsi ea hore nate e tla hlepha, e phethohe, kapa e oe joaloka li-fasteners tsa mechini, 'me ha ho na matšoenyeho a HAZ a tšoanang le ho tjheseletsa.

Ho Feto-fetoha ha Thepa: Carbide Flow Drill Bits e sebetsana ka katleho le thepa e fapaneng likoloing tsa sejoale-joale: tšepe e bobebe, tšepe ea High-Strength Low-Alloy (HSLA), Advanced High-Strength Steel (AHSS), li-alloy tsa aluminium (5xxx, 6xxx), esita le likarolo tse ling tse sa hloekang. Liaparo tsa lisebelisoa (joalo ka AlCrN bakeng sa aluminium, TiAlN bakeng sa tšepe) li ntlafatsa ts'ebetso le bophelo.

Likopo tsa Bohlokoa tsa Likoloi Ho Amohela ho Khanna:

Li-enclosures le Literei tsa Betri ea EV: Mohlomong ke mokhanni a le mong e moholo ka ho fetisisa. Meaho ena e meholo, e nang le mabota a masesaane (hangata aluminium) e hloka lintlha tse ngata tse matla haholo, tse sa lutleng bakeng sa ho kenya, ho koahela, ho pholisa lipoleiti le likarolo tsa motlakase. TFD e fana ka matla a hlokahalang ntle le ho eketsa boima kapa ho rarahana. Sekoti se koetsoeng se thusa ho thibela ho kena ha sehatsetsing.

Chassis le Subframes: Li-bracket, litho tse tšekaletseng, le lintlha tsa ho kenya tse emisitsoeng li rua molemo matla a TFD le khanyetso ea ho thothomela litšepeng tse tšesaane, tse matla haholo.

Diforeimi le Mekgwa ya Setulo: Dikarolo tsa bohlokwa tsa polokeho tse hlokang matla a ho hula a phahameng haholo bakeng sa diankora tsa lebanta le dintlha tse tiileng tsa ho kenya. TFD e fedisa di-fasteners tse kgolo le ho sotha ho tjheseletsa.

'Mele o Mosweu (BIW): Li-bracket tse fapaneng, li-reinforcement, le libaka tsa ho kenya kahare ka har'a sebopeho sa koloi moo linate tse ekelitsoeng li leng boima 'me ho tjheseletsa ho sa ratehe.

Mekhoa ea ho ntša mosi: Li-hangers tsa ho kenya le lihokelo tsa tšireletso ea mocheso holim'a tšepe e tšesaane e sa hloekang kapa tšepe e entsoeng ka aluminiamo li rua molemo masobeng a koetsoeng a sa senyeheng le ho hanyetsa ho thothomela.

Diyuniti tsa HVAC le Diphanele tsa ho kenya: Dintlha tsa ho kenya le diphanele tsa phihlello ya tshebeletso tse hlokang dikgwele tse tiileng ka hara dikobo tse tshesane tsa tshepe.

Bohlokoa ba Carbide ho TFD ea Likoloi:

Mesebetsi ea tlhahiso ea likoloi e telele, e hloka ts'epo e felletseng ea lisebelisoa le bophelo bo bolelele. Li-Drill Bits tsa Carbide Flow ha li buisanoe. Li mamella mocheso o feteletseng oa khohlano (hangata o fetang 800°C/1472°F ntlheng), lebelo le phahameng la ho potoloha, le matla a bohlokoa a axial a kopanang le makhetlo a likete ka shift. Li-substrate tse tsoetseng pele tsa carbide ea lithollo tse nyane le liaparo tse khethehileng (TiAlN, AlTiN, AlCrN) li etselitsoe thepa e itseng ea likoloi, li eketsa bophelo ba lisebelisoa le ho boloka sebopeho se tsitsitseng sa bushing le boleng ba masoba bo bohlokoa bakeng sa lits'ebetso tse iketsang. E hlokometsoeng hantleSete ea li-Bit tsa Thermal Friction Drille ka sebetsana le masoba a likete pele e hloka ho nkeloa sebaka, e fana ka moruo o motle oa litšenyehelo ka masoba.

Kopanyo le Bokamoso:

Ho kopanngoa ka katleho ho kenyelletsa taolo e nepahetseng ea RPM, sekhahla sa phepelo, matla a axial, le pholiso (hangata ho phatloha ho fokolang ha moea ho fapana le ho futhumatsa sehatsetsi ho qoba ho tima sehatsetsi se etsang). Litsamaiso tsa tlhokomelo li latela ho tsofala ha lisebelisoa le liparamente tsa ts'ebetso bakeng sa tlhokomelo e boletsoeng esale pele. Ha moralo oa likoloi o ntse o sutumelletsa pele ho ea meahong ea thepa e mengata (mohlala, 'mele ea aluminium liforeiming tsa tšepe) le ho bobebe le ho feta, tlhoko ea theknoloji ea Flow Drill e tla eketseha feela. Bokhoni ba eona ba ho theha likhoele tse sebakeng seo, tse matla haholo ka thepa e tšesaane, e fapaneng, ka kotloloho ka har'a phallo ea tlhahiso e iketsang, e beha Thermal Friction Drilling eseng feela e le mokhoa o mong, empa e le tekanyetso ea nakong e tlang bakeng sa ho tiisa likoloi ka katleho le ka matla. Ke phetoho e thehileng ka khutso likoloi tse matla, tse bobebe ka sehatsetsi se le seng se kopaneng ka nako.

Nako ea poso: Phato-21-2025