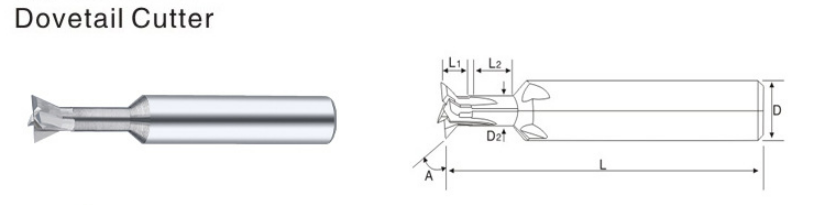

Qalabka Jarjarrada Shidaalka ee Tungsten Carbide Dovetail

Shayga oo dhan waxa laga sameeyay bir tungsten tayo sare leh, oo leh adkaysi sare iyo iska caabin sare oo xirasho. Isticmaalka agab bir ah oo tayo sare leh, oo leh iska caabin dhul gariir oo wanaagsan. Waxa laga sameeyay bir bir ah oo tungsten ah oo cusub oo tayo fiican leh, kaas oo leh iska caabin sare oo xirasho iyo xoog. Waa mindi dovetail tayo sare leh oo loogu talagalay codsiyada jarista xawaaraha sare ee adkaysiga sare leh. Waxa ay samayn kartaa farsamayn xawaare sare leh oo ku saabsan birta aan miridhku lahayn, aluminiumka dahaarka leh, birta la shubay iyo agab kale oo ka hooseeya HRC55 (oo ay ku jirto HRC55). Makiinadaha, yaraynta tirada isbeddellada qalabka iyo hagaajinta hufnaanta.

Faa'iidada:

Kharash ahaan waxtar leh waxaanan doorannaa birta tungsten tayo sare leh oo leh adkeysi sare iyo iska caabin sare oo xirasho ah

Dhismaha mashiinka saxda ah, shiidid fiican. Hagaajinta saxda ah, burrs yar oo ku jira habaynta badeecada - siman sare

Xakamaynta tayada adag, saxnaanta sare iyo alaabada la dhammeeyay oo fiiqan

Sifo:

1. Xaglaha geeska fiiqan si weyn ayay u hagaajiyaan hufnaanta jarista

2. Naqshad toosan oo jeexdin ah, daadgurayn siman oo jajab ah iyada oo aan lagu dhejin mindi.

3. Si macquul ah uga fogow hawada oo kordhi cimriga qalabka

4. Xooji adkaanta geeska jarista, suunka geeska qaansadana wuxuu u gudbiyaa geeska dhinaca fiiqan oo si wax ku ool ah uga saar burr-ka.

5. Godadka weyn ee ka saarista jajabka ayaa jaraya xoogga, jaristana waa mid si fiican u socota, taasoo gaareysa farsamayn hufan oo heer sare ah, shaqadana waa mid aad u saxsan oo aad u cajiib badan.

| Nooca | Mashiinka Mashiinka Mashiinka ee Tungsten Dovetail | Alaab | Bir Tungsten ah |

| Qalabka Shaqada | Bir aan daxal lahayn, aluminium, bir dhiman, bir la shubay, aluminium la shubay, bir daxal leh, titanium la shubay, iwm. | Qalabka mashiinka ee khuseeya | Xarunta mashiinka CNC, qalabka mashiinka CNC, mashiinka xardho, mashiinka xardho, mashiinka xawaaraha sare leh |

| Xirmada Gaadiidka | Sanduuqa | Fuul | 3/4 |

| Dahaarka | No | Adkaanta | <=55 |

| Dhexroorka Buundada (mm) | D2 (mm) | L2 (mm) | Dhererka Buundada (mm) | Dhexroorka Shank (mm) | Wadarta Dhererka (mm) | Foornooyinka |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 | 20 | 75 | 4 |

Isticmaal:

Si ballaaran ayaa loogu isticmaalaa goobo badan

Waxsoosaarka Duulista Hawada

Soo Saarista Mashiinka

Soo saaraha baabuurta

Samaynta caaryada

Waxsoosaarka Korontada

Habaynta mashiinka la dhaqo