Munyika inokurumidza yekugadzira zvemagetsi, uko kunyatsojeka kwe micron-level kunotsanangura kubudirira, kuunzwa kweNext-Gen PCB Board Drill Bits kunoratidza kukwira kukuru mukugadzirwa kwe circuit board. Yakagadzirwa kuti iboore, inyore, uye igadzire micromachine pama printed circuit boards (PCBs) nedzimwe substrates dzakatetepa zvakanyanya, idzi Tungsten SteelMini Drill PCBZvishandiso zvinosanganisa zvinhu zvemhando yepamusoro yemuchadenga netekinoroji yekugadzikana kwepasi kuti zvitsanangure kushanda zvakanaka uye hupenyu hurefu mukugadzirwa kwezvinhu zvakawanda.

Hunyanzvi hweUinjiniya: Nei Tungsten Steel Ichikosha

Pakati pezvinhu izvi zvekuboorera pane tungsten carbide (WC) ine hutsanana hwakanyanya, chinhu chakasarudzwa nekuda kwekuoma kwayo kusingaenzaniswi (HRA 92), kuramba kupfeka, uye kusimba kwechimiro. Kusiyana nemabhora eHSS (High-Speed Steel) echinyakare, dhizaini iyi yesimbi yetungsten inopa:

Nguva Yehupenyu Hwakareba 3X: Inokwanisa kutsungirira mabhora ekuboorera anopfuura 15,000 pamapuranga eFR-4 fiberglass pasina kuora kwemucheto.

Maumbirwo eMicro-Grain: Sub-0.5µm carbide grains inoita kuti mipendero yekucheka ive yakapinza, zvichiita kuti dhayamita yemaburi ive diki se0.1mm ine ±0.005mm inoshivirira.

Dhizaini Inodzivirira Kutsemuka: Kusimbaradzwa kwehunde kunodzivirira kutsemuka panguva yekushanda kwe-RPM yakakwira (30,000–60,000), kunyangwe muPCB yakagadzirwa neceramic yakapfava.

Kuongororwa kwechitatu nePrecision Machining Institute of Technology kunosimbisa kuti mabhiti aya anochengetedza Ra 0.8µm surface finish mushure memaburi zviuru gumi - chinhu chakakosha pakuvimbika kwemasaini epamusoro mumidziyo ye5G neIoT.

Kugadzikana Kwepasi: Kucheka Pasina Kubvumirana

Kuboorwa kwePCB kunoda kugadzikana kwakakwana kudzivirira "kufamba" kana kusarongeka kwemaburi. Proprietary Seismic Blade Edge Design inotarisa izvi kuburikidza ne:

Flute Geometry isina kuenzana: Inoenzanisa kubviswa kwema chips uye damping vibration, ichideredza simba remativi ne40%.

Angle yeHelix Yakaputirwa Nesimbi: Helix ye30° ine TiAlN coating inoderedza kupisa (<70°C) panguva yekushanda nguva dzose.

Magoroo Anodzivirira Kurira: Ma micro-channels akachekwa neLaser anokanganisa ma frequency e harmonic, zvichiita kuti positional ikwane mukati me 5µm pa 10-layer PCBs.

Mukuyedza kwekumanikidzwa kwakaitwa pakuboora maburi e0.3mm kuburikidza nemabhodhi e2mm akafukidzwa nearuminiyamu, maburi aya haana kutsauka mukati memaawa mazana mashanu akatevedzana - chinhu chisingaenzaniswi nevakwikwidzi.

Mashandisirwo Mumaindasitiri Ese

Zvigadzirwa zvemagetsi zvevatengi

Kune vagadziri vemabhodhibhodhi emafoni:

0.2mm Micro-Vias: Yakawana mwero we99.9% wegoho pamabhodhi eHDI ane layer 12.

20% Kukurumidza Kudya Kwemhuka: Kunogoneswa nekudzikira kwekukweshana uye kuvharika kwemachipisi.

Zvemagetsi zveMotokari

Mukugadzirwa kwemodule yemagetsi emagetsi:

Kuvimbika Kwemaburi Anopinda Nepaburi: Kuchengetedza kuenderera mberi kwemagetsi 100% muzvikamu zvinofambisa kupisa zvine ukobvu hwe1.6mm.

Kushanda Pasina Kutonhodza: Kugona kuboora mabhatiri netsvina kunodzivirira kusvibiswa mumasisitimu ekuchengetedza mabhatiri akavharwa.

Ndege neDziviriro

Kuboora maburi e 0.15mm mumasekete e polyimide flex:

Kusabvisa ganda: Kunyangwe munzvimbo dzine hunyoro hwakawanda hwe200°C.

Kugadzira Mapatani eEMI Shield: Kunyora nemazvo machira ekudzivirira eRF akavakirwa pagraphene.

Magadzirirwo ehunyanzvi

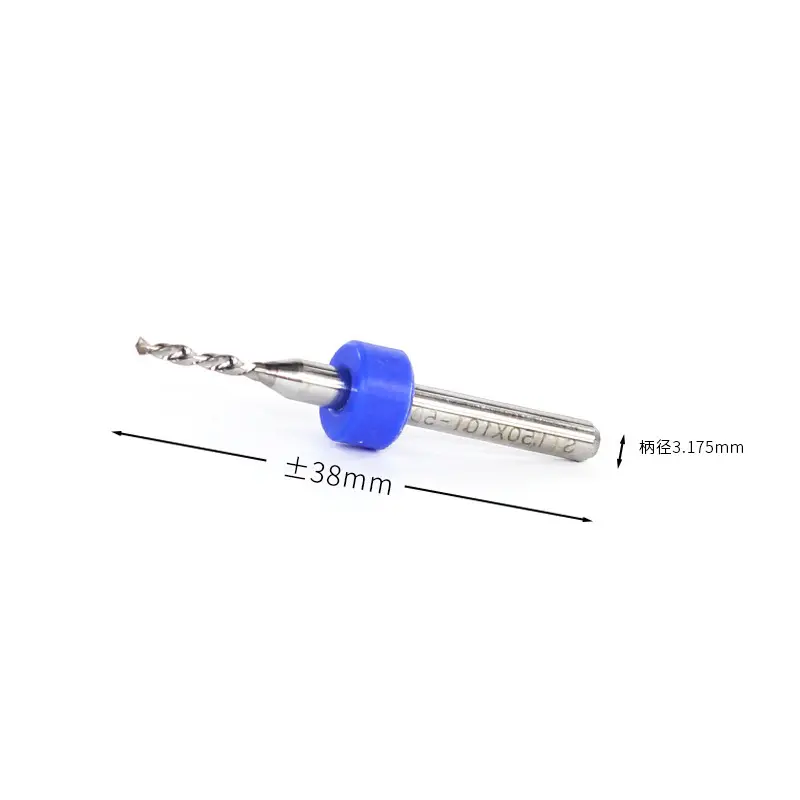

Dhayamita Range: 0.1mm–3.175mm (0.004"–1/8")

Rudzi rweShank: Standard 3.175mm (1/8") kana kuti custom ER collet compatibility

Sarudzo dzeKupfeka: TiN (goridhe), TiCN (bhuruu), kana Diamond-Like Carbon (DLC)

Kureba kweRPM: 80,000 (zvichienderana nedhayamita)

Kuenderana: Michina yekuboora yeCNC, michina yekuboora yePCB inongoerekana yagadzirwa, maturusi anotenderera anotorwa nemaoko

Kushanda Nemari Zvakagadziriswazve

Ongororo yemitengo nemabhenefiti yakaitwa nemugadziri wePCB wekuTaiwan yakaratidza kuti:

Mari Yegore Negore ye$18,500: Kuderedzwa kwekushandiswa kwezvidhinha zvechidhinha (kubva pa12 kusvika ku4 seti pagore).

Kuderedza Simba 15%: Zvinodiwa zvishoma zve spindle torque.

Kusashandazve: Kubvisa $220k pagore mumabhodhi akaraswa kubva mukutenderera kwedhiri.

Kugara Kuchigara Kwakavakirwa

Kurongedza: Matreyi efuro anoora 100%.

Kutevedzera RoHS & REACH: Hapana lead, cadmium, nezvimwe zvinhu zvine njodzi.

Hupenyu hweChishandiso Chakawedzerwa: Kushandiswa kwetungsten kwakaderera ne60% zvichienzaniswa nekuboorerwa kwakajairika.

Uchapupu hweMushandisi

"Kuchinja kushandisa tungsten steel bits idzi kwaichinja," anodaro Hiroshi Tanaka, Maneja weKugadzira paKyoto-based sensor. "Tiri kuchera makomba zviuru makumi maviri pakuchinjana pasina shanduko yemidziyo - chimwe chinhu chisingafungidzike neHSS drills yedu yekare. Dhizaini yekudengenyeka kwenyika chete inodzikisa maburi edu ne95%.

Sei Uchifanira Kusarudza Aya Mabhodhi EPCB Drill?

Kunyatsojeka Kusingaputsike: Kune kunyatsojeka kwakaita selaser mumabhodhi e-high-density interconnect (HDI).

Kumhanya Pasina Kurasikirwa: Boora maburi e 0.3mm pamaburi e 400 paminiti pasina kukanganisa kunaka kwemupendero.

Kuenderana Kwese: Inoshanda neFR-4, Rogers, aruminiyamu, uye kunyange magirazi-reinforced laminates.

Dhizaini Inodzivirira Remangwana: Yakagadzirirwa zvinhu zvePCB zvechizvarwa chinotevera zvakaita sema dielectric asina halogen uye ane kurasikirwa kwakanyanya.

Mhedziso

Muindasitiri umo micron yega yega inotungamira purofiti uye mashandiro, idzi Tungsten SteelMabhodhi ePCB ekuboorerahazvisi zvekushandisa chete - zvinobatsira pakugadzira zvinhu. Nekubatanidza sainzi yezvinhu neinjiniya yekugadzikana, zvinopa simba vagadziri kuti vapfuure miganhu yekushandiswa kwezvigadzirwa zvishoma uku vachideredza

Nguva yekutumira: Kurume-21-2025