HRC65 Black Nano-Tech Stainless Processing Flat End Mill

Chinhu:

1. Zvidimbu zvakacheneswa zvakagadzirwa nesimbi yeTungsten + michina yekugadzira inounzwa kunze kwenyika.

Tinoshandisa 100% tungsten carbide base material, uye tinoramba kushandisa zvinhu zvinoshandiswazve kana zvinhu zvinogadziriswazve.

2. Takatora michina yeSACCKE kubva kuGermany kuti igayiwe zvakanaka kuti igare yakasimba uye ipedziswe zvakanaka.

3. Kupatsanurana kusina kuenzana uye kona isina kuenzana ye helix kudzivirira kurira uye kuwedzera kupedzwa kwepamusoro pezvikamu zvakagadziriswa.

4.HRC65.

5. Kuputira kweALoCa kwakatorwa neSwitzerland, kudzivirira kupisa uye kuramba kupisa kwakanyanya, kugaya kwakasimba.

Kuomarara kwekuputira ~3500HV uye tembiricha yekurwisa okisijeni ye950 degrees.

6. Maitiro ekuita matanho/flute inotenderera inokwesha, kubvisa chips zvakapfava panguva yekucheka nekukurumidza, hapana kuunganidzwa kwema chips/kusaunganidzwa kwema chips, zviri nani kuvandudza mashandiro ekugadzira uye kuvandudza kupera kwema workpiece.

| Nyeredzi | 4 | Zvinhu | Titanium alloy, simbi isina ngura | ||||||||||

| Rudzi | Rudzi rwemusoro wakatsetseka | Kuoma | HRC65 | ||||||||||

| Pasuru |

| Rudzi | MSK | ||||||||||

| Dhayamita yeFrute (mm) | Kureba kweFlute (mm) | Dhayamita yeShank(mm) | Kureba (mm) | ||||||||||

| 1 | 3 | 4 | 50 | ||||||||||

| 1.5 | 4 | 4 | 50 | ||||||||||

| 2 | 6 | 4 | 50 | ||||||||||

| 2.5 | 7 | 4 | 50 | ||||||||||

| 3 | 8 | 4 | 50 | ||||||||||

| 4 | 11 | 4 | 50 | ||||||||||

| 5 | 13 | 6 | 50 | ||||||||||

| 6 | 15 | 6 | 50 | ||||||||||

| 8 | 20 | 8 | 60 | ||||||||||

| 10 | 25 | 10 | 75 | ||||||||||

| 12 | 30 | 12 | 75 | ||||||||||

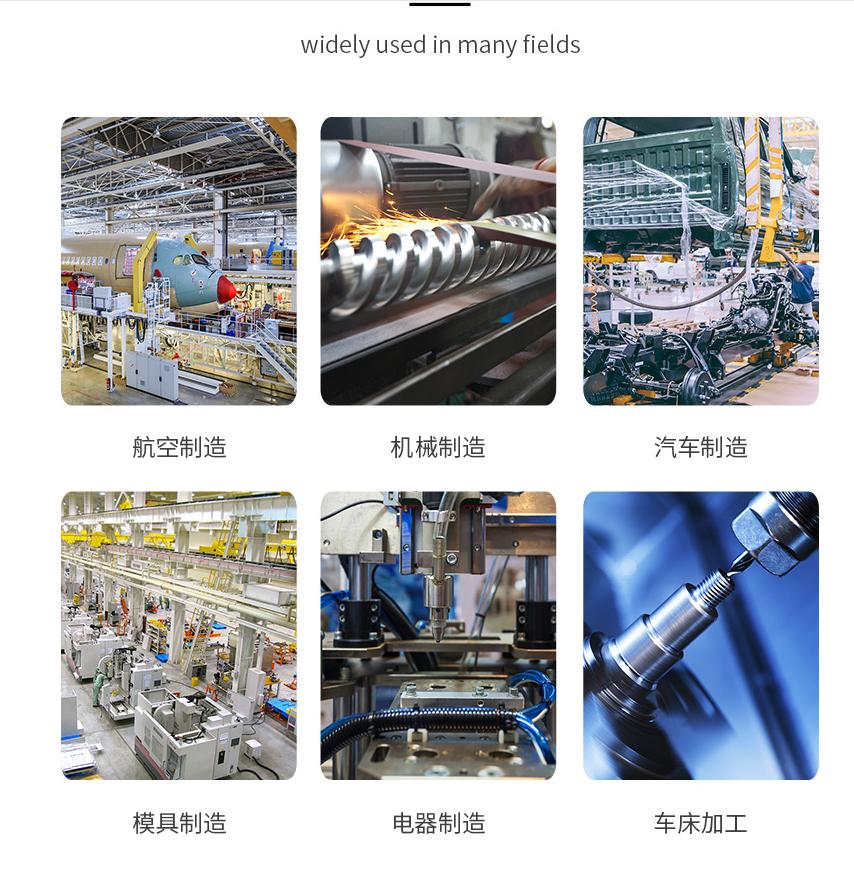

Shandisa:

Inoshandiswa zvakanyanya muminda yakawanda

Kugadzira Ndege

Kugadzirwa kweMichina

Mugadziri wemotokari

Kugadzira chakuvhuvhu

Kugadzira Magetsi

Kugadziriswa kwelathe