Mu isi yihuta cyane yo gukora ibikoresho by'ikoranabuhanga, aho ubuziranenge bw'urwego rwa micron bugaragaza intsinzi, ishyirwaho rya Next-Gen PCB Board Drill Bits rigaragaza intambwe ikomeye mu gukora circuit board. Yakozwe mu gucukura, gushushanya no gukoresha micromachine ku mbaho zacapwe (PCBs) n'izindi substrates nto cyane, izi Tungsten SteelPCB nto yo gucukuraIbikoresho bihuza ibikoresho byo mu kirere n'ikoranabuhanga ryo kudahungabana kw'imirasire kugira ngo bisobanure neza kandi birambe mu gukora ibintu byinshi.

Ubuhanga mu by'Ubwubatsi: Impamvu Tungsten Steel Ifite Ishingiro

Ishingiro ry'izi mashini zo gucukura ririmo tungsten carbide (WC) ifite isuku nyinshi, ibikoresho byatoranijwe kubera ubukana bwayo budasanzwe (HRA 92), kudashira kw'ingufu, no kuba imiterere yayo imeze neza. Bitandukanye n'imashini zisanzwe za HSS (High-Speed Steel), iyi mashini ya tungsten itanga ibi bikurikira:

Igihe kirekire cya 3X: Ishobora kwihanganira imiyoboro irenga 15,000 yo gucukura ku mbaho za fiberglass za FR-4 idasenyuka.

Imiterere y'uduti duto: Uduti twa karubide duto duto dupima impande zo gukata nk'urwembe, bigatuma habaho uburebure bw'umwobo bungana na mm 0.1 hamwe n'ubushobozi bwo kwihanganira ± mm 0.005.

Igishushanyo mbonera cy’ingufu zirwanya kuvunika: Imiterere y’ingufu zikomeje kurinda kuvunika mu gihe cy’ibikorwa bya RPM nyinshi (30.000–60.000), ndetse no mu bikoresho bya PCB byuzuyemo ceramic.

Isuzuma ryakozwe n’ikigo cya gatatu cy’ikoranabuhanga cya Precision Machining Institute of Technology ryemeza ko izi bits zigumana ubuso bwa Ra 0.8µm nyuma y’imyobo 10.000 - ikintu cy’ingenzi mu gutuma ibimenyetso birushaho kuba byiza mu bikoresho bya 5G na IoT.

Ubudahangarwa bw'imitingito: Gukata nta gutandukana

Gucukura PCB bisaba ubusugire busesuye kugira ngo hirindwe "kugenda" cyangwa kutagenda neza kw'umwobo. Igishushanyo mbonera cya Proprietary Seismic Blade Edge Design kibivuga muri ibi bikurikira:

Jometri y'Ifiriti Idahuje: Ipima uburyo bwo gukuraho uduce duto tw'imashini no kudatuma ibintu bitigita, ikagabanya imbaraga zo ku ruhande ku kigero cya 40%.

Inguni ya Helix ifite Nano-Coated: Helix ya 30° ifite TiAlN coating igabanya ubushyuhe bwinshi (<70°C) mu gihe cy'imikorere idahwema.

Imiyoboro Irwanya Gusubiramo: Imiyoboro mito ikozwe muri laser ibangamira umurongo wa harmonic, bigatuma ahantu hagaragara neza muri metero 5 kuri PCB zifite urwego 10.

Mu igeragezwa ryo gucukura imyobo ya 0.3mm mu mbaho za 2mm zipfundikiye aluminiyumu, utwo duce twagaragaje ko nta gutandukana na gato mu gihe cy’amasaha 500 yikurikiranya - ikintu kitagereranywa n’abandi bahanganye.

Porogaramu mu nganda zose

Ikoranabuhanga rikoreshwa n'abaguzi

Ku bakora motherboard ya terefone zigendanwa:

Micro-Vias ya 0.2mm: Yageze ku gipimo cya 99.9% cy'umusaruro ku mbaho za HDI zifite urwego rwa 12.

Igipimo cyihuse cya 20% cyo gutanga ibiryo: Biterwa no kugabanuka kw'ibiryo no kuziba kw'ibice by'amapine.

Ibyuma by'ikoranabuhanga by'imodoka

Mu gukora module y'amashanyarazi ya EV:

Kwizerwa mu mwobo unyura mu mwobo: Gukomeza 100% by'amashanyarazi mu bice bitwara ubushyuhe bifite ubunini bwa mm 1.6.

Gukora nta gikonjesha: Ubushobozi bwo gucukura bwumutse burinda kwanduzanya mu buryo bwo gucunga bateri zifunze.

Ibyerekeye Ikiresiteri n'Ubwunganizi mu by'Indege

Gucukura imyobo ya 0.15mm mu miyoboro ya polyimide flex:

Kudahindura imiterere y'ubutaka: Nubwo haba hari ubushyuhe bwinshi bwa 200°C.

Ibishushanyo bya EMI Shield: Gushushanya neza imiterere y'ibikoresho byo kurinda RF bishingiye kuri graphene.

Ibisobanuro bya tekiniki

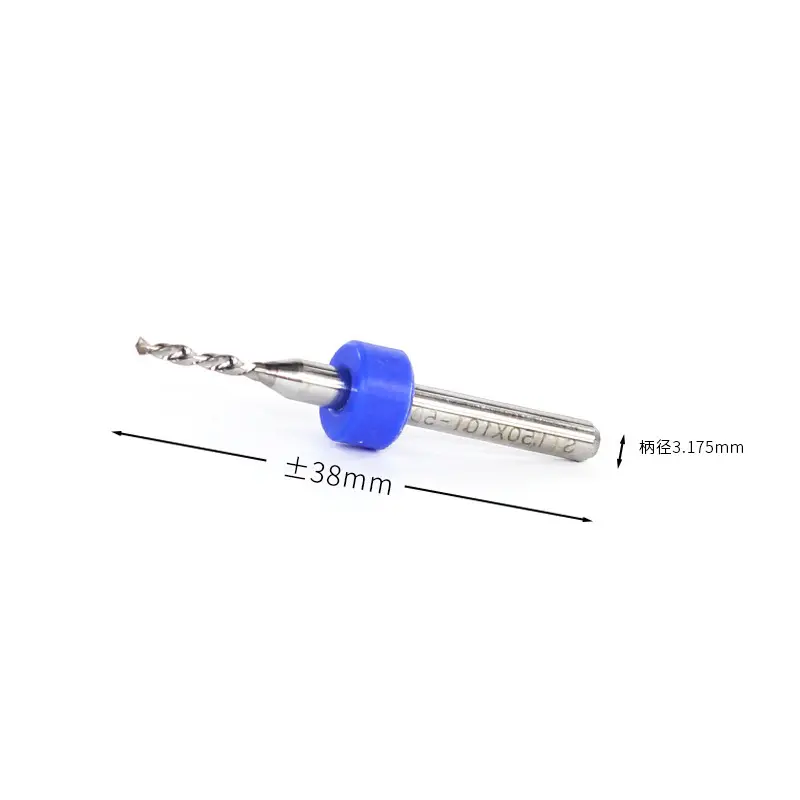

Ingano y'umurambararo: 0.1mm–3.175mm (0.004"–1/8")

Ubwoko bwa Shank: Ingano isanzwe ya 3.175mm (1/8") cyangwa ijyanye na ER collet yihariye

Amahitamo yo gusiga: TiN (izahabu), TiCN (ubururu), cyangwa Diyama nka Karuboni (DLC)

RPM ntarengwa: 80.000 (biterwa n'umurambararo)

Guhuza: Imashini zicukura za CNC, imashini zicukura za PCB zikora ku buryo bwikora, ibikoresho bizunguruka bikoreshwa mu ntoki

Uburyo bwo Kunoza Ikiguzi Bwongeye Gusobanurwa

Isesengura ry’inyungu n’ikiguzi ryakozwe n’umuhanga mu gukora PCB wo muri Tayiwani ryagaragaje:

Amafaranga 18,500 yo kuzigama ku mwaka: Kugabanya ikoreshwa ry’ibikoresho byo gucukura (kuva kuri seti 12 kugeza kuri 4 ku mwaka).

Kugabanya Ingufu 15%: Ibisabwa kugabanya imbaraga zo gukoresha spindle.

Nta Gusubiramo: Byakuyeho $220k/umwaka mu mbaho zashaje zavuye mu gucukura.

Uburambe bwubatswemo

Gupakira bishobora kongera gukoreshwa: Amasahani y'ifuro ashobora kubora 100%.

Kuyubahiriza RoHS na REACH: Nta lisansi, cadmium, n'ibindi bintu biteza akaga.

Igihe cy'ibikoresho biramba: 60% by'ikoreshwa rya tungsten ugereranije n'imyitozo isanzwe.

Ubuhamya bw'abakoresha

"Gukoresha utwo duce tw'icyuma cya tungsten byari impinduka," ibi ni ibyavuzwe na Hiroshi Tanaka, Umuyobozi ushinzwe umusaruro mu ruganda rukora sensor rukorera i Kyoto. "Turimo gucukura imyobo 20.000 kuri buri simburana nta gikoresho gihinduka - ikintu kidashoboka mu myitozo yacu ya HSS ishaje. Igishushanyo mbonera cya 'seismic' cyonyine cyagabanyije uburyo twanze imyobo ku kigero cya 95%.

Kuki wahitamo utu duce two gucukura uduce twa PCB?

Ubuziranenge Budacika: Ku bijyanye n'ubuziranenge nk'ubwa laser mu mbaho zifite ubucucike bwinshi (HDI).

Umuvuduko Udahenze: Gucukura imyobo ya 0.3mm ku myobo 400 ku munota nta kwangiza ubwiza bw'inkombe.

Ikorana na bose: Ikorana na FR-4, Rogers, aluminiyumu, ndetse na laminate zikomejwe n'ibirahuri.

Igishushanyo mbonera cy’ejo hazaza: Biteguye ibikoresho bya PCB byo mu gihe kizaza nka dielectric zidafite halogen na dielectric zitakaza cyane.

Umwanzuro

Mu nganda aho buri micron igena inyungu n'imikorere, izi Tungsten SteelUduce two gucukura uduce tw'imashini zo gucukura uduce twa PCBni ibirenze ibikoresho gusa - ni inyungu mu bya tekiniki. Mu guhuza ubumenyi bw'ibikoresho n'ubuhanga bwo gushimangira umutekano, biha imbaraga abakora ibikoresho kugira ngo barenge imipaka ya miniaturization mu gihe bagabanya

Igihe cyo kohereza ubutumwa: Werurwe-21-2025