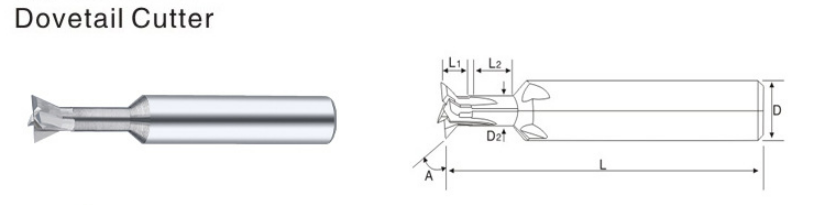

Chida Chodulira Miyala cha Tungsten Carbide Dovetail

Chinthu chonsecho chapangidwa ndi chitsulo cha tungsten chapamwamba kwambiri, cholimba kwambiri komanso cholimba kwambiri. Chimagwiritsa ntchito chitsulo cha alloy cholimba kwambiri, cholimba bwino komanso cholimba kwambiri. Chimapangidwa ndi mipiringidzo yatsopano yachitsulo cha tungsten, yomwe imakhala ndi mphamvu zambiri komanso yolimba kwambiri. Ndi mpeni wa dovetail wapamwamba kwambiri wogwiritsidwa ntchito podula mwachangu komanso molimba kwambiri. Chimatha kugwira ntchito mwachangu kwambiri pa chitsulo chosapanga dzimbiri, aluminiyamu, chitsulo chopangidwa ndi zinthu zina pansi pa HRC55 (kuphatikiza HRC55). Kukonza makina, kuchepetsa kuchuluka kwa kusintha kwa zida ndikuwongolera magwiridwe antchito.

Ubwino:

Yotsika mtengo ndipo timasankha chitsulo cha tungsten chapamwamba kwambiri chokhala ndi kuuma kwakukulu komanso kukana kuvala kwambiri

Kupanga makina molondola, kupukusa bwino. Kukonza bwino, kuchepetsa ma burrs pakukonza zinthu - kusalala kwambiri

Kuwongolera khalidwe kolimba, kulondola kwambiri komanso zinthu zomalizidwa bwino

Mbali:

1. Makona akuthwa kwambiri amathandiza kwambiri kudula bwino

2. Kapangidwe kowongoka kwa groove, kutulutsa chip chosalala popanda kumamatira ku mpeni

3. Pewani mpweya moyenera ndikuwonjezera moyo wa chidacho

4. Limbikitsani kulimba kwa m'mphepete mwachitsulo, ndipo lamba wa m'mphepete mwachitsulocho umayendetsa bwino m'mphepete mwachitsulo chakuthwa ndikuchotsa bwino m'mphepete mwake.

5. Mzere waukulu wochotsera ma chips umadula mphamvu, ndipo kudulako kumakhala kosalala, zomwe zimapangitsa kuti ntchitoyo ikhale yogwira ntchito bwino, ndipo ntchitoyo ndi yolondola komanso yodabwitsa.

| Mtundu | Chodulira Chodulira cha Tungsten Dovetail | Zinthu Zofunika | Chitsulo cha Tungsten |

| Zopangira Ntchito | Chitsulo chosapanga dzimbiri, aluminiyamu, chitsulo chofewa, chitsulo choponyedwa, aluminiyamu alloy, chitsulo chosakanikirana, titaniyamu alloy, ndi zina zotero. | Chida chogwiritsira ntchito makina | Malo opangira makina a CNC, chida cha makina a CNC, makina osemedwa, makina osemedwa, makina othamanga kwambiri |

| Phukusi Loyendera | Bokosi | Chitoliro | 3/4 |

| Kuphimba | No | Kuuma | <=55 |

| Chitoliro cha m'mimba mwake (mm) | D2(mm) | L2(mm) | Kutalika kwa chitoliro (mm) | Chimake cha Shank (mm) | Utali Wonse (mm) | Zitoliro |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 | 20 | 75 | 4 |

Gwiritsani ntchito:

Amagwiritsidwa ntchito kwambiri m'magawo ambiri

Kupanga Ndege

Kupanga Makina

Wopanga magalimoto

Kupanga nkhungu

Kupanga Zamagetsi

Kukonza lathe