Popanga ndi kupanga ma printed circuit board (PCBs), kulondola ndikofunikira kwambiri. Chimodzi mwa zinthu zofunika kwambiri pakupanga ma PCB ndi drill bit yomwe imagwiritsidwa ntchito kuboola mabowo a zigawo ndi zotsalira. Mu bukhuli, tifufuza mitundu yosiyanasiyana yaZidutswa za PC board drill, momwe amagwiritsidwira ntchito, komanso momwe mungasankhire chobowolera choyenera cha polojekiti yanu.

Dziwani zambiri za ma PC board drill bits

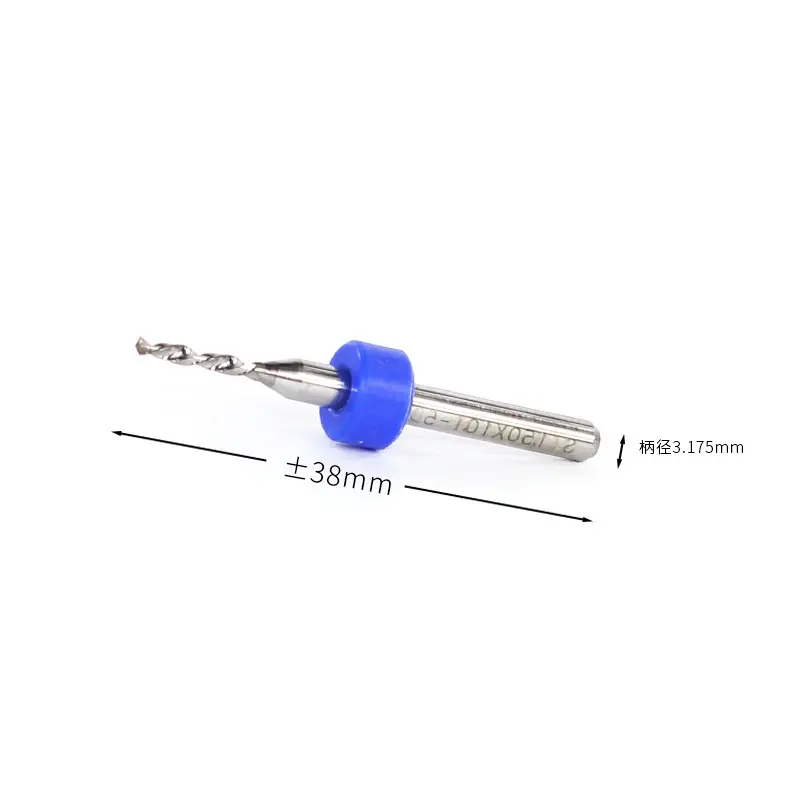

Chobowolera cha PCB ndi chida chopangidwira makamaka kubowola mabowo mu ma PCB. Zobowolera izi zimapangidwa kuti zigwire ntchito ndi zipangizo zapadera ndi makulidwe a ma PCB, zomwe nthawi zambiri zimakhala ndi fiberglass, epoxy, ndi zinthu zina zophatikizika. Chobowolera choyenera chingakhudze kwambiri mtundu wa PCB yanu, zomwe zimakhudza chilichonse kuyambira kukhulupirika kwa maulumikizidwe anu mpaka magwiridwe antchito onse a chipangizo chanu chamagetsi.

Mitundu ya Ma Drill Bits Osindikizidwa a Circuit Board

1. Chobowolera chopotoka: Uwu ndi mtundu wofala kwambiri wa chobowolera chomwe chimagwiritsidwa ntchito kwambiri pa ma PCB. Chili ndi kapangidwe ka spiral groove komwe kumathandiza kuchotsa zinyalala pobowola. Chobowolera chopotoka chimagwiritsidwa ntchito m'njira zosiyanasiyana ndipo chingagwiritsidwe ntchito m'mabowo osiyanasiyana, zomwe zimapangitsa kuti chikhale chosankhidwa chodziwika bwino pakati pa anthu osaphunzira komanso akatswiri.

2. Ma Micro Drill: Pa ntchito zomwe zimafuna mabowo ang'onoang'ono kwambiri, ma micro drill ndi ofunikira. Ma drill bits awa amatha kuboola mabowo ang'onoang'ono ngati 0.1 mm, zomwe zimapangitsa kuti akhale abwino kwambiri pama PCB okhala ndi malo ochepa. Komabe, amafunika kusamalidwa mosamala komanso njira zobowolera bwino kuti asasweke.

3. Ma Carbide Drill Bits: Opangidwa ndi tungsten carbide, ma drill bits awa amadziwika kuti ndi olimba komanso amatha kukhala okhwima kwa nthawi yayitali. Ndi othandiza kwambiri pobowola zinthu zolimba ndipo nthawi zambiri amagwiritsidwa ntchito m'malo opanga ma PCB akatswiri.

4. Ma Drill Bits Ophimbidwa ndi Daimondi: Kuti zinthu zikhale zolondola komanso zokhalitsa, ma drill bits ophimbidwa ndi daimondi ndi chisankho chabwino kwambiri. Ma drill bits ophimbidwa ndi daimondi amapangitsa kuti kubowola kukhale kosalala komanso kumachepetsa chiopsezo cha kusweka kapena kusweka kwa zinthu za PCB. Ma drill bits amenewa nthawi zambiri amakhala okwera mtengo, koma pama projekiti abwino, ndi oyenera kuyikamo ndalama.

Sankhani chobowola choyenera

Mukasankha chobowolera cha PC board choyenera pa polojekiti yanu, ganizirani zinthu zotsatirazi:

- Zipangizo: Mtundu wa zipangizo zomwe zimagwiritsidwa ntchito pa PCB udzakhudza kusankha kwa drill bit. Pa ma circuit board a FR-4, drill drill bit yopotoka kapena carbide drill bit nthawi zambiri imakhala yokwanira. Pazinthu zapadera kwambiri, monga ma PCB a ceramic kapena chitsulo, drill bit yophimbidwa ndi diamondi ingafunike.

- Kukula kwa Dzenje: Dziwani kukula kwa dzenje lomwe likufunika kubooledwa. Ngati kapangidwe kanu kali ndi mabowo wamba komanso ang'onoang'ono, mungafune kuyika ndalama mu zobowola zopotoka ndi zobowola zazing'ono.

- Njira Yoboolera: Njira yoboolera imakhudzanso kusankha ma drill bit. Ngati mukugwiritsa ntchito makina a CNC, onetsetsani kuti drill bit ikugwirizana ndi zida zanu. Kuboolera ndi manja kungafunike zinthu zosiyanasiyana, monga drill bit yolimba kuti ipirire kupsinjika.

- BAJETI: Ngakhale kuti n'kovuta kusankha chobowola chotsika mtengo kwambiri, kuyika ndalama mu chobowola chapamwamba kwambiri kungakupulumutseni nthawi ndi ndalama mtsogolo. Chobowola choyipa chingayambitse kuwonongeka kwa bolodi la circuit komanso zolakwika zokwera mtengo.

Pomaliza

Mu dziko la kapangidwe ndi kupanga ma PCB, zida zoyenera zingathandize kwambiri. Mukamvetsetsa mitundu yosiyanasiyana ya ma PC board drill bits ndi momwe amagwiritsidwira ntchito, mutha kusankha njira yabwino kwambiri pa projekiti yanu. Kaya ndinu wokonda zosangalatsa kapena katswiri, kuyika ndalama mu drill bit yabwino kudzaonetsetsa kuti ma PCB anu apangidwa molondola komanso modalirika. Kuboola kosangalatsa!

Nthawi yotumizira: Januwale-07-2025