Ib qho kev tsim khoom tshiab uas tsom mus rau cov khoom siv laum tshiab (tseem hu ualub tshuab tho qhov thermal frictions lossis flowdrill) tab tom hloov pauv txoj kev lag luam tsim cov xov muaj zog, txhim khu kev qha hauv cov hlau nyias thiab cov raj. Cov thev naus laus zis no tshem tawm qhov xav tau kev khawb thiab tapping ib txwm muaj, muab cov txiaj ntsig zoo hauv lub zog, kev ceev, thiab kev siv nyiaj tsawg, tshwj xeeb tshaj yog hauv kev lag luam tsheb, aerospace, thiab electronics.

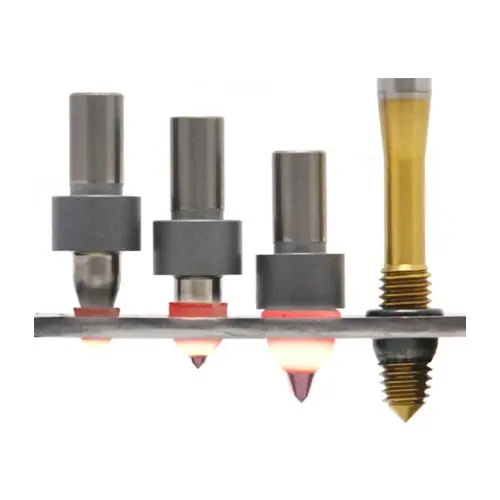

Lub hauv paus tseem ceeb ntawm kev tsim kho tshiab yog nyob rau hauv cov txheej txheem tshwj xeeb uas ua los ntawm cov ntsis tshwj xeeb no. Tsis zoo li cov laum ib txwm muaj uas txiav thiab tshem tawm cov khoom, cov laum ntws tsim cov cua sov hnyav los ntawm kev sib xyaw ua ke ntawm kev sib hloov ceev heev thiab kev tswj hwm axial siab. Thaum lub taub hau tungsten carbide tshwj xeeb kov qhov chaw ua haujlwm, kev sib txhuam sai sai ua rau cov hlau hauv qab - feem ntau yog hlau, stainless hlau, txhuas, lossis tooj liab alloys - kom nws lub xeev yas (kwv yees li 600-900 ° C nyob ntawm cov khoom siv).

Lub bushing no yog ib qho tseem ceeb heev. Feem ntau nws ntev txog li 3 npaug ntawm qhov tuab qub ntawm cov khoom siv hauv paus. Piv txwv li, kev xov ib daim ntawv tuab 2 hli ua rau muaj lub dab tshos siab 6 hli. Qhov no ua rau qhov tob ntawm kev sib txuas xov ntau dua li qhov yuav ua tau nrog cov khoom siv raw tuab ib leeg.

Tom qab tsim cov bushing, cov txheej txheem feem ntau txuas ntxiv mus seamlessly. Ib tug txheem kais ua raws li covqhov dej ntws, tam sim ntawd hauv tib lub voj voog tshuab (ntawm cov khoom siv sib xws) lossis hauv kev ua haujlwm tom qab. Lub kais txiav cov xov meej meej ncaj qha rau hauv lub bushing tshiab, phab ntsa tuab. Vim tias lub bushing yog ib feem ntawm cov qauv noob thawj, tsis yog ib qho ntxig ntxiv, cov xov uas tshwm sim muaj qhov tseeb siab thiab lub zog siab.

Cov Txiaj Ntsig Tseem Ceeb Uas Tsav Kev Txais Yuav:

Lub Zog Tsis Muaj Qhov Sib Xws Hauv Cov Khoom Nyias: Lub 3x bushing muab kev sib koom ua ke zoo dua piv rau kev kov lub hauv paus tuab ncaj qha lossis siv cov ntxig.

Kev Ceev & Kev Ua Haujlwm Zoo: Muab kev ua qhov thiab kev tsim bushing ua ke rau hauv ib qho kev ua haujlwm ceev heev (feem ntau yog vib nas this rau ib qhov), tshem tawm cov kauj ruam sib cais ntawm kev khawb, kev tshem tawm cov kab nrib pleb, thiab kev teeb tsa ntxig.

Kev Txuag Khoom Siv: Tsis muaj cov chips tshwm sim thaum lub sijhawm drilling, txo cov khoom pov tseg.

Cov Qws Kaw: Cov khoom siv uas raug tshem tawm ntws nruj nreem ncig lub qhov, feem ntau tsim cov qws tsis xau uas zoo tagnrho rau cov kua dej lossis cov ntawv thov siab.

Txo Cov Cuab Yeej Siv: Tshem tawm qhov xav tau cov txiv ntoo, cov txiv ntoo vuam, lossis cov ntxig riveted, ua kom yooj yim rau BOMs thiab kev xa khoom.

Cov Txheej Txheem Huv Si: Tsawg kawg nkaus chips thiab tsis tas yuav siv cov kua txiav hauv ntau daim ntawv thov (qee zaum siv lubrication rau lub neej me ntsis lossis cov ntaub ntawv tshwj xeeb).

Muaj ntau daim ntawv thov: Cov thev naus laus zis tau txais kev rub sai sai txhua qhov chaw uas cov ntaub ntawv nyias nyias xav tau cov xov sib txuas zoo:

Tsheb: Cov tais roj teeb tsheb fais fab, cov khoom chassis, cov brackets, cov pa tawm, cov thav rooj zaum.

Aerospace: Cov vaj huam sib luag sab hauv, cov kav dej, cov khoom siv sib zog.

Cov Khoom Siv Hluav Taws Xob: Cov racks server, cov vaj huam sib luag kaw, cov dab dej kub.

HVAC: Cov hlau ducting sib txuas, brackets.

Rooj Tog & Khoom Siv Hauv Tsev: Cov thav duab uas xav tau cov qhov khi uas zais thiab ruaj khov.

Cov chaw tsim khoom ntawm cov khoom siv laum txuas ntxiv txhim kho cov qauv geometries, coatings, thiab cov khoom siv sib xyaw kom ntev lub neej ntawm cov cuab yeej, txhim kho kev ua tau zoo ntawm cov hlau alloys siab heev, thiab ua kom zoo dua cov txheej txheem rau kev ua haujlwm tsis siv neeg. Raws li kev lag luam tsis tu ncua nrhiav kev ua kom lub cev hnyav thiab kev tsim khoom zoo, kev sib txhuam thermal, powered los ntawm cov tshiabkev khawb dej ntwsntsis, tau ua pov thawj tias yog ib qho kev daws teeb meem tseem ceeb rau kev tsim cov xov ua haujlwm siab uas lawv ib zaug tsis yooj yim sua lossis tsis siv tau. Lub sijhawm ntawm kev tawm tsam nrog cov xov tsis muaj zog hauv cov ntawv nyias nyias tab tom muab txoj hauv kev rau lub zog thiab yooj yim ntawm kev sib txhuam-tsim bushings.

Lub sijhawm tshaj tawm: Lub Xya Hli-30-2025