Hauv cov lag luam uas qhov kev ua kom raug, kev ceev, thiab kev siv tau yooj yim yog qhov tseem ceeb, Tungsten Carbide Rotary Burrs nruab nrog Ib thiab Ob Lub Taub Hau Sib Tsoo Hlau tau tshwm sim los ua qhov hloov pauv kev ua si. Tsim los ua kom tau raws li qhov xav tau ntawm kev tsim khoom niaj hnub, kev ua pwm, thiab kev ua tes ua haujlwm, cov cuab yeej rotary siab heev no muab kev ua tau zoo tsis sib xws thoob plaws cov hlau thiab cov hlau tsis yog hlau. Txawm hais tias kev ua kom cov hlau carbon siab lossis kev ua kom zoo nkauj, lubCarbide Rotary Burr Teebua ke cov khoom siv ruaj khov nrog kev ua kom raug, ua rau nws yog qhov tseem ceeb ntxiv rau cov chaw ua haujlwm, cov chaw tsim khoom, thiab cov chaw ua yeeb yam thoob ntiaj teb.

Kev Siv Tau Ntau Yam Khoom Siv Tsis Sib Xws

Lub zog tseem ceeb ntawm cov noTungsten Carbide Rotary BurrsNws yog lawv lub peev xwm los ua ntau yam khoom siv zoo kawg nkaus. Txij li cov hlau hnyav xws li hlau, hlau cam khwb cia, hlau bearing, hlau carbon siab, hlau alloy, thiab hlau stainless mus rau cov khoom mos dua xws li tooj liab, txhuas, marble, jade, thiab pob txha, cov cuab yeej no hloov kho tau yooj yim. Qhov kev hloov pauv no tshem tawm qhov xav tau ntau yam cuab yeej tshwj xeeb, ua kom cov haujlwm ua haujlwm yooj yim dua hauv kev lag luam xws li kev tsim khoom tsheb, kev tsim kho aerospace, kev tsim cov hniav nyiaj hniav kub, thiab kev txiav pob zeb.

Lub Taub Hau Sib Tsoo Hlau Ob Chav ua rau qhov kev hloov pauv no zoo dua. Los ntawm kev sib koom ua ke ob qib carbide lossis geometries sib txawv rau hauv ib lub burr, cov neeg siv tuaj yeem ua cov haujlwm sib xyaw - xws li roughing thiab finishing - yam tsis tas hloov cov cuab yeej. Qhov kev ua haujlwm ob npaug no muaj txiaj ntsig zoo hauv kev ua pwm, qhov twg cov qhov sib xyaw ua ke xav tau ob qho tib si tshem tawm cov khoom siv hnyav thiab cov ntsiab lus zoo heev.

Kev Ua Tiav Zoo Tshaj Plaws & Muaj Peev Xwm Ua Tau Zoo

Tsim los rau qhov zoo tshaj plaws, cov rotary burrs no ua rau cov tiav du zoo kawg nkaus nrog kev siv zog tsawg kawg nkaus. Lawv cov hniav txiav tungsten carbide uas raug sib tsoo kom ntseeg tau tias muaj kev sib cuag tas li nrog cov workpieces, txo qhov sib tham thiab txo qhov kev ua tiav tom qab. Qhov no ua rau:

Qhov zoo ntawm qhov chaw: Ua tiav cov xim zoo li daim iav ntawm cov hlau lossis cov ntsiab lus zoo meej ntawm cov ntaub ntawv tawg yooj yim xws li marble thiab pob txha.

Cov qauv geometries nyuaj: Tsim cov pwm qhov, cov qhov hauv qab, thiab cov duab nrog qhov tseeb sub-millimeter.

Txo cov haujlwm thib ob: Tshem tawm qhov xav tau kev xuab zeb lossis txhuam hauv ntau daim ntawv thov, txuag lub sijhawm thiab cov nqi zog ua haujlwm.

Cov Hlau Ib LeegLub Taub Hau Sib TsooQhov kev xaiv no ua tau zoo heev rau cov haujlwm tshwj xeeb uas xav tau kev txiav sib xws, xws li kev tshem cov pob qij txha vuam lossis kev ua kom zoo nkauj ntawm cov khoom siv cav. Lub caij no, tus qauv tsim ob lub taub hau muab kev ywj pheej tsis muaj qhov sib piv rau ntau theem.

Tsim los rau kev ceev, Tsim los rau kev ua siab ntev

Zoo rau kev siv nrog cov cuab yeej hluav taws xob, cov cuab yeej pneumatic, lossis CNC tshuab, cov ntaub ntawv rotary no ua haujlwm tau zoo ntawm qhov ceev ntawm 6,000 txog 50,000 RPM. Qhov ntau yam no ua kom muaj kev sib raug zoo nrog ntau yam khoom siv, los ntawm cov tshuab sib tsoo tes mus rau cov chaw machining kev lag luam. Cov yam ntxwv tseem ceeb suav nrog:

Kev tiv thaiv thermal: Tungsten carbide lub zog tiv thaiv kub tiv thaiv kev hloov pauv txawm tias thaum siv ceev ceev ntev.

Lub neej ntev dua: Ua tau zoo dua li cov cuab yeej HSS txog li 20 npaug, cov burrs no tiv taus kev hnav, chipping, thiab corrosion.

Txo kev co: Cov taub hau sib tsoo sib npaug ua rau muaj kev ruaj khov, txo cov neeg ua haujlwm qaug zog thiab txhim kho kev tswj hwm.

Cov Ntawv Thov Thoob Plaws Kev Lag Luam

Kev Tsim Pwm & Tuag: Zoo meej rau kev tsim cov pwm txhaj tshuaj siab, cov pwm stamping, lossis cov cuab yeej siv hauv aerospace.

Kev Tsim Khoom Hlau: Tshem tawm, chamfer, thiab cov khoom zoo nkauj hauv tsheb, nkoj tsim, lossis cov haujlwm hlau.

Kos Duab & Duab Puab: Txiav cov qauv zoo nkauj rau hauv pob zeb, pob txha, lossis cov hlau muaj nqis yam tsis muaj kev cuam tshuam rau cov khoom siv zoo nkauj.

Kev Txij Nkawm & Kev Kho: Kho cov khoom siv tshuab, lub taub hau cav, lossis kho cov khoom sib xyaw nrog kev phais kom raug.

Kev Ua Khoom Siv Hniav Nyiaj Hniav Kub: Kos cov qauv zoo nkauj rau ntawm kub, nyiaj, lossis pob zeb diamond.

Cov Lus Qhia Txog Kev Siv

Khoom siv: Premium tungsten carbide nrog cobalt binder rau kev txhim kho toughness thiab hnav tsis kam.

Qhov Loj ntawm Shank: 3 hli (sib xws nrog feem ntau cov cuab yeej rotary thiab collets).

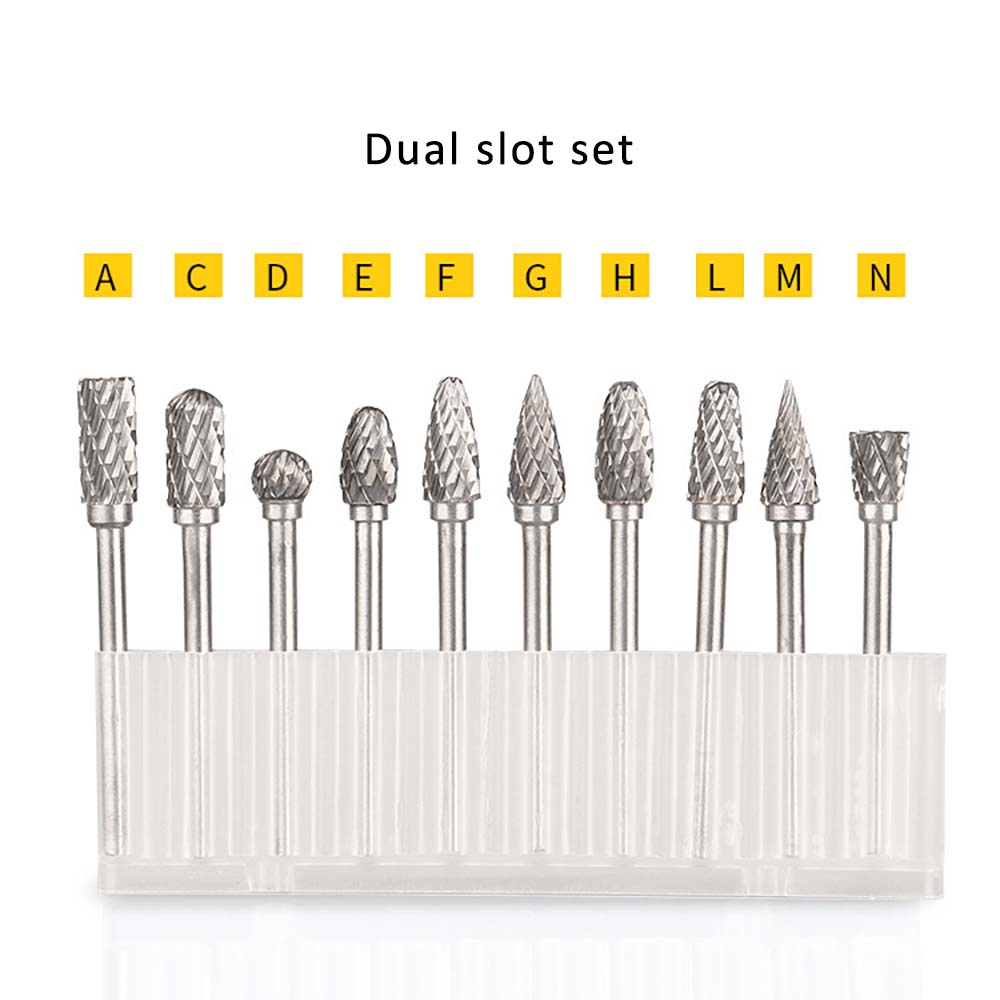

Hom Lub Taub Hau Sib Tsoo: Ib zaug txiav (rau kev ua tiav zoo) thiab ob zaug txiav (rau kev tshem tawm cov khoom lag luam hnyav).

Kev Ua Raws Cai Kev Nyab Xeeb: Ua tau raws li ISO 9001 thiab ANSI cov qauv, nrog cov shanks txhawb kom tiv thaiv kev tawg.

Vim li cas ho xaiv qhov Carbide Rotary Burr Set no?

Kev Siv Nyiaj Txiag Zoo: Txo cov nqi khoom siv nrog ib pawg uas tuav ntau yam khoom siv thiab cov haujlwm sib txawv.

Txuag Lub Sijhawm: Hloov ntawm kev ntxhib thiab kev ua tiav hauv vib nas this, ua tsaug rau qhov tsim ob lub taub hau.

Ergonomic Tsim: Lub teeb yuag, cov txheej tiv thaiv kev plam, thiab qhov sib npaug zoo tshaj plaws txhim kho kev nplij siab rau tus neeg siv thaum siv ntev.

Txhim Kho Koj Lub Rooj Sib Tham Niaj Hnub No

Tshawb nrhiav seb peb lub Tungsten Carbide Rotary Burrs uas yog ib lub thiab ob lub taub hau sib tsoo hlau tuaj yeem ua rau koj muaj peev xwm ua haujlwm tau zoo thiab raug dua li cas. Mus saibhttps://www.mskcnctools.com/los tshawb nrhiav cov ntaub ntawv qhia txog kev siv tshuab, thov cov qauv, lossis tiv tauj peb pab neeg kws tshaj lij kom tau txais cov lus qhia tshwj xeeb.

Lub sijhawm tshaj tawm: Tsib Hlis-12-2025