Hauv kev nrhiav kev tsim khoom kom muaj zog dua, sib dua, thiab ua haujlwm tau zoo dua, thev naus laus zis hloov pauv tau txais kev txhawb nqa tseem ceeb: Thermal Friction Drilling (TFD). Cov txheej txheem tshiab no, uas muaj zog los ntawm kev tshwj xeebCov Khoom Siv Thermal Friction Drill Bits, tab tom txhais dua tshiab txog yuav ua li cas kev lag luam tsim cov kev sib txuas xov zoo hauv cov hlau nyias, tshem tawm qhov xav tau cov txiv ntoo ib txwm muaj, cov txiv ntoo vuam, lossis cov rivets cumbersome.

Lub Ntsiab Lus Tshiab: Kub, Kev Sib Txhuam, thiab Kev Ntsuas Tseeb

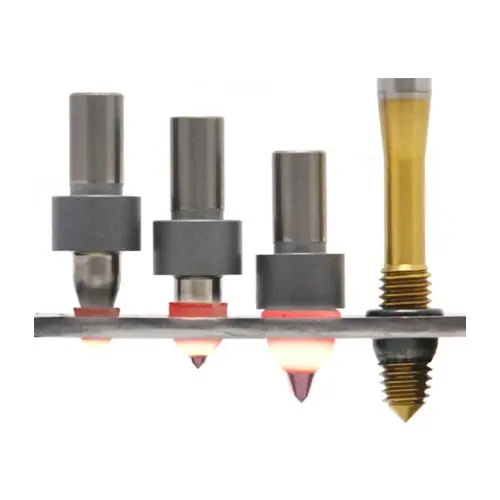

Lub hauv paus ntawm TFD yog lub hauv paus ntsiab lus ntawm kev tsim cov cua sov hauv zos los ntawm kev ua haujlwm ntawm lub tshuab. Lub Flow Drill ua haujlwm siab, feem ntau muaj lub taub hau carbide uas tsis yooj yim hnav, tig ntawm qhov ceev heev (feem ntau yog 2000-5000 RPM) thaum muaj kev nyuaj siab axial. Kev sib txhuam tsim ntawm Carbide Flow Drill Bit tig thiab cov khoom siv workpiece (hlau, txhuas, stainless hlau, thiab lwm yam) sai sai ua rau cov hlau kub ntawm qhov chaw sib cuag kom ze lossis dhau nws qhov kub plasticization - feem ntau ntawm 500 ° C txog 1000 ° C nyob ntawm cov khoom siv.

Dhau Qhov Kev Tshawb Fawb: Tsim Kom Muaj Zog Sib Koom Ua Ke

Qhov no yog qhov uas TFD hla dhau qhov kev khawb ib txwm muaj. Raws li cov khoom siv yas tsim tawm, cov qauv geometry tshwj xeeb ntawmKev Ntsuas Dejtsis yog tsuas yog txiav xwb; nws ua rau cov hlau molten txav mus rau sab nraud thiab sab hauv qab. Qhov kev ntws no tsim cov bushing zoo li tus thawj coj ncaj qha los ntawm cov khoom niam txiv nws tus kheej. Qhov tseem ceeb, lub bushing no yog kwv yees li 3 npaug ntawm qhov tuab ntawm cov hlau thawj. Qhov kev nce ntxiv ntawm cov khoom siv tuab nyob ib puag ncig lub qhov yog qhov tseem ceeb rau TFD lub zog kom zoo dua.

Kauj Ruam Kawg: Kev Sib Txuas Lus Zoo

Thaum lub bushing tau tsim thiab pib txias, Flow Drill rov qab los. Cov txheej txheem feem ntau hloov mus rau kev tapping seamlessly. Ib lub tap txheem (lossis qee zaum koom ua ke rau hauv cov cuab yeej ua ke) raug tsav los ntawm lub bushing tshiab tsim, tseem sov. Tapping rau hauv qhov seem tuab dua no, es tsis yog cov khoom siv nyias nyias, ua rau cov xov muaj kev kam rau siab thiab muaj zog tshwj xeeb. Cov qauv noob ntawm cov khoom hloov pauv thiab kho dua tshiab feem ntau pab txhawb kev tiv thaiv kev qaug zog piv rau cov xov txiav.

Vim li cas kev lag luam thiaj li txais yuav Flow Drills:

Lub Zog Tsis Muaj Qhov Sib Piv: Cov xov sib txuas cov khoom siv 2-3 zaug tuab dua li daim ntawv hauv paus, muab lub zog rub tawm thiab stripping ntau dua li cov qhov tapped ib txwm lossis ntau lub txiv ntoo clinch.

Kev Txuag Khoom Siv: Tshem tawm qhov xav tau ntxiv cov khoom siv txuas xws li txiv ntoo, txiv ntoo vuam, lossis txiv ntoo rivet, txo cov khoom seem, qhov hnyav, thiab cov khoom muag.

Kev Ua Haujlwm Zoo: Muab kev tho qhov, kev tsim bushing, thiab kev tapping rau hauv ib qho kev ua haujlwm sai, ntawm cov tshuab CNC txheem lossis cov cell tshwj xeeb. Tsis tas yuav xuas ua ntej lossis kev ua haujlwm thib ob.

Cov Pob Qij Txha Kaw: Cov yas ntws feem ntau tsim kom muaj qhov chaw du thiab kaw, txhim kho kev tiv thaiv xeb thiab tiv thaiv cov kua dej xau.

Kev Siv Tau Ntau Yam: Zoo heev rau ntau yam hlau ductile, los ntawm cov hlau tsis muaj zog thiab txhuas mus rau cov hlau tsis xeb thiab qee cov alloys.

Thaj Chaw Txo Qhov Kub Cuam Tshuam (HAZ): Txawm hais tias muaj cua sov los xij, cov txheej txheem no nyob hauv thaj chaw tshwj xeeb, txo qhov kev cuam tshuam lossis kev hloov pauv ntawm cov hlau rau cov khoom siv ib puag ncig piv rau kev vuam.

Cov Ntawv Thov Tsav Tsheb Xav Tau:

Cov txiaj ntsig tshwj xeeb ntawm Thermal Friction Drill Bit Sets yog nrhiav tau cov ntawv thov tseem ceeb thoob plaws cov kev lag luam xav tau:

- Tsheb: Cov khoom ntawm lub chassis, cov thav rooj zaum, cov brackets, cov roj teeb (EVs), cov pa tawm - txhua qhov chaw uas muaj zog, cov xov txhim khu kev qha hauv cov hlau nyias yog qhov tseem ceeb.

- Kev ya dav hlau: Cov qauv sib dua, cov khoom sab hauv, cov khoom siv avionics - tau txais txiaj ntsig los ntawm kev txuag qhov hnyav thiab kev khi ruaj khov.

- HVAC & Khoom Siv: Cov ntawv hlau thaiv, cov kav dej, cov compressor mounts - xav tau cov pob qij txha ruaj khov, tiv taus qhov xau.

- Cov Khoom Siv Hluav Taws Xob: Cov txee server, cov txee tswj - xav tau cov ntsiab lus mounting muaj zog yam tsis muaj cov khoom siv kho vajtse ntxiv.

- Lub Zog Rov Ua Dua Tshiab: Cov thav duab vaj huam sib luag hnub ci, cov khoom siv cua tshuab - xav tau kev ruaj khov hauv cov khoom nyias nyias uas raug rau qhov chaw ib puag ncig hnyav.

Qhov zoo ntawm Carbide:

Cov xwm txheej hnyav ntawm qhov taub ntawm lub qhov tho - kev sib txhuam hnyav, kub siab, thiab kev nyuaj siab loj - xav tau cov cuab yeej uas muaj qhov nyuaj thiab kev ruaj khov thermal. Carbide Flow Drill Bits, feem ntau muaj cov txheej txheem tshwj xeeb (xws li TiAlN), yog tus qauv kev lag luam. Lawv qhov kev tiv thaiv kev hnav ua kom muaj qhov zoo sib xws, kev tsim bushing, thiab lub cuab yeej siv tau ntev, ua rau Thermal Friction Drill Bit Set yog qhov kev daws teeb meem pheej yig txawm tias pib nqis peev rau cov cuab yeej.

Xaus lus:

Kev Siv Thermal Friction Drilling, uas siv tau los ntawm cov Carbide Flow Drill Bits thiab cov txheej txheem Flow Drill zoo tshaj plaws, tsis yog tsuas yog ib txoj kev ua qhov xwb. Nws yog ib txoj kev hloov pauv khoom siv uas tsim lub zog ncaj qha rau hauv cov khoom nyias nyias. Los ntawm kev tsim cov bushings tuab, sib xyaw rau cov xov muaj zog siab hauv ib qho kev ua haujlwm zoo, TFD daws cov teeb meem kev sib txuas ruaj khov, txo cov nqi, thiab ua rau cov qauv tsim sib dua thiab muaj zog dua. Thaum kev thov tsim khoom rau kev ua haujlwm zoo thiab kev ua tau zoo zuj zus, kev siv cov thev naus laus zis Flow Drill tshiab no tau npaj rau kev loj hlob tseem ceeb, ua kom nws qhov chaw ruaj khov ua lub hauv paus ntawm kev ua haujlwm hlau niaj hnub.

Lub sijhawm tshaj tawm: Lub Yim Hli-07-2025