Hauv lub ntiaj teb ceev ceev ntawm kev tsim khoom siv hluav taws xob, qhov twg micron-level precision txhais tau tias kev vam meej, qhov kev qhia txog Next-Gen PCB Board Drill Bits cim qhov kev dhia ceev hauv kev tsim khoom ntawm lub rooj tsavxwm. Tsim los rau kev khawb, kos duab, thiab micromachining ntawm cov laug cam luam tawm (PCBs) thiab lwm yam khoom siv ultra-thin, cov Tungsten Steel noPCB laum me meCov cuab yeej siv ua ke cov khoom siv hauv aerospace nrog cov thev naus laus zis tiv thaiv av qeeg los txhais dua qhov ua tau zoo thiab lub neej ntev hauv kev tsim khoom ntau.

Kev Ua Zoo Tshaj Plaws Hauv Kev Tsim Kho: Vim Li Cas Tungsten Steel Tseem Ceeb

Lub plawv ntawm cov laum no yog cov tungsten carbide (WC) uas muaj purity siab, ib yam khoom siv xaiv rau nws qhov sib xyaw ua ke ntawm qhov nyuaj (HRA 92), kev tiv taus hnav, thiab kev ruaj khov ntawm cov qauv. Tsis zoo li cov laum HSS (High-Speed Steel) ib txwm muaj, cov hlau tungsten no muab cov hauv qab no:

3X Lub Neej Ntev Dua: Tiv taus 15,000+ lub voj voog drilling ntawm FR-4 fiberglass boards yam tsis muaj ntug degradation.

Cov Qauv Me Me: Cov carbide nplej uas qis dua 0.5µm ua kom cov npoo txiav ntse heev, ua tiav qhov loj li 0.1 hli nrog kev kam rau siab ±0.005 hli.

Tsim Kev Tiv Thaiv Kev Tawg: Cov qauv ntawm cov ceg tawv uas muaj zog tiv thaiv kev tawg thaum lub sijhawm ua haujlwm siab-RPM (30,000–60,000), txawm tias nyob rau hauv cov ntaub ntawv PCB uas muaj cov khoom siv ceramic.

Kev sim los ntawm cov neeg thib peb los ntawm Precision Machining Institute of Technology lees paub tias cov khoom no tswj tau Ra 0.8µm qhov tiav tom qab 10,000 qhov - qhov tseem ceeb rau kev ua haujlwm ntawm lub teeb liab siab hauv 5G thiab IoT cov khoom siv.

Kev Ruaj Ntseg ntawm Av Qeeg: Txiav Tsis Muaj Kev Cuam Tshuam

Kev tho PCB xav tau kev ruaj khov kom tiv thaiv "kev taug kev" lossis qhov tsis sib xws. Tus Qauv Tsim Ntug Hniav Seismic Proprietary daws qhov no los ntawm:

Asymmetric Flute Geometry: Sib npaug ntawm kev tshem tawm cov chip thiab kev co, txo cov zog sab nraud los ntawm 40%.

Lub Nano-Coated Helix Angle: Lub 30° helix nrog TiAlN txheej txo qhov kub thiab txias (<70°C) thaum lub sijhawm ua haujlwm tas mus li.

Cov Qhov Rooj Tiv Thaiv Kev Sib Txuas Lus: Cov kab me me uas siv Laser-etched cuam tshuam cov zaus harmonic, ua kom muaj qhov tseeb ntawm qhov chaw hauv 5µm hla 10-txheej PCBs.

Hauv kev sim siab uas tau khawb cov qhov 0.3 hli los ntawm 2 hli txhuas-clad boards, cov khoom no tau qhia txog xoom qhov kev hloov pauv dhau 500 lub voj voog sib law liag - ib qho kev ua tiav uas cov neeg sib tw tsis muaj qhov sib piv.

Cov Ntawv Thov Thoob Plaws Kev Lag Luam

Cov Khoom Siv Hluav Taws Xob Rau Cov Neeg Siv Khoom

Rau cov chaw tsim khoom ntawm cov motherboard smartphone:

0.2 hli Micro-Vias: Ua tiav 99.9% cov txiaj ntsig ntawm 12-txheej HDI boards.

20% Kev Pub Noj Sai Dua: Ua kom muaj kev sib txhuam tsawg dua thiab kev txhaws ntawm cov chips.

Tsheb Khoom Siv Hluav Taws Xob

Hauv kev tsim cov khoom siv fais fab EV:

Kev Ntseeg Tau Los Ntawm Qhov: Tswj tau 100% kev sib txuas hluav taws xob hauv cov khoom siv thermal-conductive uas tuab 1.6 hli.

Kev Ua Haujlwm Tsis Muaj Dej Txias: Lub peev xwm khawb qhuav zam kev ua qias tuaj hauv cov kab ke tswj roj teeb kaw.

Kev Ua Si thiab Kev Tiv Thaiv Huab Cua

Kev khawb qhov 0.15 hli hauv cov voj voog polyimide flex:

Tsis muaj kev sib cais: Txawm tias nyob rau hauv 200 ° C qhov chaw muaj av noo siab.

EMI Shield Patterning: Kev kos duab meej rau cov txheej tiv thaiv RF raws li graphene.

Cov Lus Qhia Txog Kev Siv

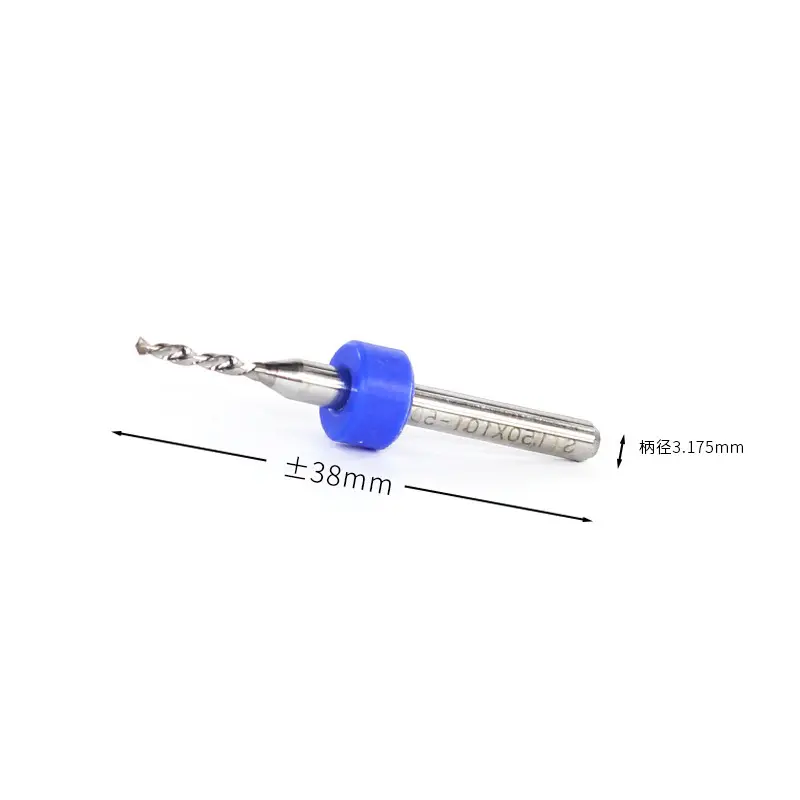

Qhov ntau thiab tsawg ntawm txoj kab uas hla: 0.1 hli–3.175 hli (0.004"–1/8")

Hom Shank: Txheem 3.175mm (1/8 ") lossis kev cai ER collet sib xws

Cov Kev Xaiv Txheej: TiN (kub), TiCN (xiav), lossis Pob Zeb Diamond-Like Carbon (DLC)

RPM siab tshaj plaws: 80,000 (nyob ntawm txoj kab uas hla)

Kev Sib Tw: CNC drilling tshuab, automated PCB laum presses, handheld rotary cov cuab yeej

Kev Siv Nyiaj Txiag Zoo Dua Tshiab

Ib qho kev tshuaj xyuas tus nqi thiab cov txiaj ntsig los ntawm tus thawj coj PCB Taiwanese tau qhia tias:

$18,500 Kev Txuag Txhua Xyoo: Txo cov kev hloov cov ntsis laum (los ntawm 12 mus rau 4 pawg/xyoo).

Txo Zog 15%: Qhov yuav tsum tau ua kom lub spindle torque qis dua.

Tsis Rov Ua Dua Tshiab: Tshem tawm $ 220k / xyoo hauv cov laug cam pov tseg los ntawm kev khawb av.

Kev Ruaj Ntseg Tsim Los Hauv

Cov Ntim Khoom Siv Rov Siv Dua: 100% cov tais ua npuas dej uas lwj tau.

RoHS & REACH Ua Raws Cai: Tsis muaj txhuas, cadmium, thiab lwm yam tshuaj lom.

Siv Tau Ntev Dua: Siv tungsten tsawg dua 60% piv rau cov laum txheem.

Cov Lus Pov Thawj ntawm Cov Neeg Siv

"Kev hloov mus siv cov tungsten steel bits no tau hloov pauv ntau heev," Hiroshi Tanaka, Tus Thawj Coj Kev Tsim Khoom ntawm lub tuam txhab tsim khoom sensor hauv Kyoto hais. "Peb tab tom tho 20,000 lub qhov rau ib qho kev hloov pauv yam tsis muaj kev hloov pauv cuab yeej - ib yam dab tsi uas peb xav tsis thoob nrog peb cov HSS drills qub. Tus qauv tsim seismic ib leeg txiav peb cov qhov-qhov chaw tsis lees paub los ntawm 95%.

Vim li cas thiaj xaiv cov PCB Board Drill Bits no?

Kev Ntsuas Tsis Tawg: Rau qhov raug zoo li laser hauv cov laug cam high-density interconnect (HDI).

Kev Ceev Tsis Muaj Kev Txom Nyem: Tho qhov 0.3 hli ntawm 400 qhov / feeb yam tsis muaj kev cuam tshuam rau qhov zoo ntawm ntug.

Kev Sib Tw Thoob Ntiaj Teb: Ua haujlwm nrog FR-4, Rogers, txhuas, thiab txawm tias cov iav-reinforced laminates.

Tsim Qauv Uas Ua Tau Yav Tom Ntej: Npaj Txhij Rau Cov Khoom Siv PCB tiam tom ntej xws li halogen-free thiab ultra-low-loss dielectrics.

Xaus lus

Hauv kev lag luam uas txhua lub micron dictates profitability thiab kev ua tau zoo, cov Tungsten Steel noPCB Board Drill Bitstsis yog tsuas yog cov cuab yeej xwb - lawv yog qhov zoo dua. Los ntawm kev sib koom ua ke ntawm kev tshawb fawb txog khoom siv nrog kev tsim kho kom ruaj khov, lawv ua rau cov tuam txhab tsim khoom muaj peev xwm thawb cov kev txwv ntawm kev ua kom me me thaum txiav.

Lub sijhawm tshaj tawm: Lub Peb Hlis-21-2025